Clear OPP Adhesive Packaging Tape with Cold Heat and Aging Resistance Cloth Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Cloth Tape is of polyethylene cloth as the carrier, coating with hot melt adhesive, synthetic rubber adhesive or nature rubber. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Cloth Tape: widely used for pipe wrapping, gaffers and book binding etc.

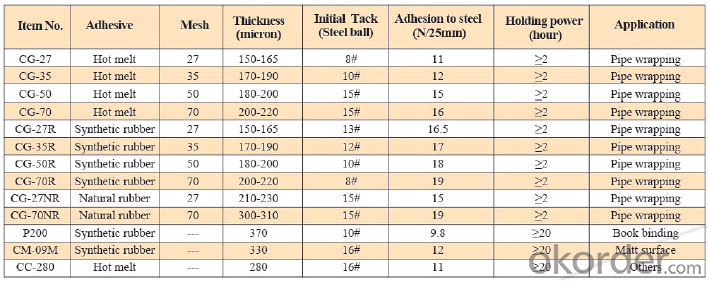

Typical Physical Reports of Bopp Tape

The thickness of the tape can be customized.

Log Roll: Length 1000mm; width 1060mm.

Cut Roll: As per customer’s requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Cloth Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Is packaging tape transparent?

- Yes, packaging tape can be transparent. Many types of packaging tape are made from clear materials such as polypropylene or acrylic, allowing them to be see-through. This transparency is beneficial as it allows users to easily see the contents of a package without having to open it. Additionally, transparent packaging tape is often preferred in situations where a clean and professional appearance is desired, as it blends in well with various types of packaging materials. However, it is important to note that not all packaging tapes are transparent, as there are also colored or printed options available for specific purposes or branding needs.

- Q: Can packaging tape be used for sealing plastic clamshell packaging?

- Indeed, plastic clamshell packaging can be effectively sealed using packaging tape. Tailored to securely seal a wide range of packaging materials, packaging tape boasts a robust adhesive bond that effectively binds the clamshell packaging, thereby preventing any unwanted opening during the transportation or handling stages. Moreover, the durability and tear resistance of packaging tape guarantee the continuous protection and sealing of the clamshell packaging throughout the entirety of its distribution journey.

- Q: What are the different types of packaging tape?

- For various packaging needs, one can find several types of packaging tape. 1. Clear Packaging Tape: The most commonly used packaging tape is clear. It is typically made from polypropylene or acrylic materials and is transparent, enabling easy visibility of labels or printed information on the package. Clear packaging tape is versatile and suitable for most general packaging applications. 2. Brown Packaging Tape: Another type of packaging tape is brown. It is also known as brown packing tape or brown carton sealing tape. This tape is made from strong and durable materials like polypropylene or paper. It is commonly used for sealing cardboard boxes or packages, providing a secure and tamper-evident seal. Brown packaging tape is ideal for shipping and general packaging purposes. 3. Masking Tape: Although not specifically designed for packaging, masking tape can be used for light-duty packaging tasks. It is made from thin and easily tearable paper. Masking tape is commonly used for holding, bundling, or labeling packages. However, it may not provide the same level of strength and security as dedicated packaging tapes. 4. Duct Tape: Similar to masking tape, duct tape is not primarily intended for packaging purposes but can be used in specific situations. It is a strong and durable tape, typically made from cloth or reinforced with fibers. Duct tape is known for its adhesive strength and versatility. It can be used for heavy-duty packaging tasks or for securing packages in challenging environments. 5. Specialty Packaging Tapes: There are various specialty packaging tapes available to cater to specific needs. Examples include fragile tape, which has a warning message to indicate delicate items inside the package, and double-sided tape, which allows for secure attachment of items or joining of materials. Additionally, there are tapes designed for specific industries, such as freezer tape for sealing packages in cold storage or electrical tape for insulating electrical wires during packaging. In conclusion, the choice of packaging tape depends on the specific requirements of the packaging task, including the type of materials being sealed, the desired level of security, and any specific conditions or considerations.

- Q: Is packaging tape safe to use on ceramic tiles?

- Yes, packaging tape is generally safe to use on ceramic tiles. Packaging tape is designed to adhere to a variety of surfaces, including ceramic tiles. However, it is important to ensure that the tape is removed carefully to avoid damaging the tile or leaving any residue behind. It is recommended to test a small inconspicuous area first to ensure that the tape does not cause any damage or discoloration. Additionally, it is always a good idea to follow the manufacturer's instructions and guidelines for using packaging tape on specific surfaces.

- Q: Can packaging tape be used for sealing cardboard boxes?

- Yes, packaging tape is commonly used for sealing cardboard boxes as it provides a strong and secure bond.

- Q: How does the electrician use waterproof insulation tape?

- Take off the film and wrap it upIf there is always water it well done so it is easy to loose ground short circuitIf the voltage is high, think of something else

- Q: Can packaging tape be used for securing pallet loads?

- Indeed, pallet loads can be secured using packaging tape. Although packaging tape is typically utilized for securing boxes and packages, it is also applicable for fortifying and securing pallet loads. It efficiently keeps the items on the pallet intact, averting any potential movements or accidents during transportation or storage. Nevertheless, it is essential to acknowledge that the efficacy of packaging tape in securing pallet loads might rely on the weight and stability of the transported items. There may be instances wherein additional strapping or banding is necessary to provide supplementary security.

- Q: Does packaging tape have an expiration date?

- No, packaging tape does not have an expiration date.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is typically designed to be easily removed without causing any harm to surfaces. However, the ease of removal can vary depending on several factors, including the type and quality of the tape, the surface it is applied to, and how long it has been in place. Most packaging tapes are created to stick firmly to surfaces during transportation or storage, ensuring that the package remains sealed and secure. Nevertheless, they are also formulated to be peeled off easily when necessary, without leaving any residue or causing damage. In most situations, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is generally developed to strike a good balance between sticking power and ease of removal. This allows for effortless removal without the need for excessive force or any sticky residue. However, there may be instances where the tape might be more challenging to remove, particularly if it has been in place for a long time or exposed to extreme temperatures. In such cases, using heat, such as a hairdryer, to soften the adhesive can be helpful, making it easier to peel off. It is important to note that the ease of tape removal can also be influenced by the surface it is applied to. Smooth and non-porous surfaces like glass or metal are generally easier to clean without causing any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to prevent any potential damage. In conclusion, while packaging tape is generally designed to be easily removed without causing damage, it is essential to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

- Q: Are there any safety precautions to consider when using packaging tape?

- Yes, there are several safety precautions to consider when using packaging tape. Firstly, it is important to ensure that you are using the tape in a well-ventilated area, as some adhesive fumes can be harmful if inhaled excessively. Additionally, it is crucial to handle the tape dispenser with care to avoid any injuries. Make sure to use proper hand placement and avoid placing your fingers too close to the cutting blade to prevent accidental cuts. Furthermore, when using packaging tape, it is advisable to wear appropriate protective gear, such as gloves, to protect your hands from any potential adhesive residue or cuts. Lastly, it is essential to store the tape in a safe and secure place, away from children or pets, to prevent any accidental ingestion or misuse. By following these safety precautions, you can ensure a safe and efficient use of packaging tape.

Send your message to us

Clear OPP Adhesive Packaging Tape with Cold Heat and Aging Resistance Cloth Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches