Chinese Best Cold Rolled Steel Coil -Excellent Process Capability

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chinese Best Cold Rolled Steel Coil JIS G 3302 -in Low Price

1.Structure of Cold Rolled Steel Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling continuous rolling, degreasing, annealing,skin pass,slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied.

2.Main Features :

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

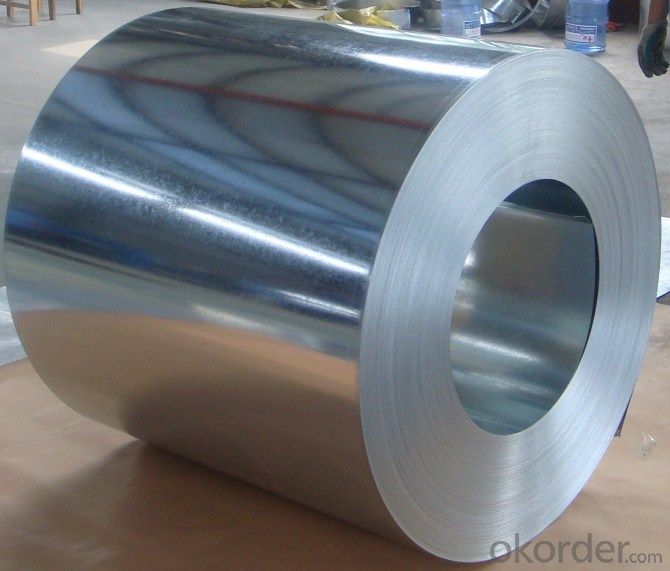

3. Cold Rolled Steel Images

4.Cold Rolled Steel Specification

Standard:AISI,ASTM,DIN,GB,JIS,JIS G3302 ASTM 653M EN10142

Grade: Q195~Q345

Thickness: 0.16mm~2.0mm

Width: 1250mm MAX

Coil weight:3-12 MT

Coil ID:508/610mm

5. FAQ of Cold Rolled Steel

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils transported and stored?

- Steel coils are typically transported and stored using specialized equipment and facilities. They are commonly transported by trucks, trains, or ships, secured with steel strapping or wire rope to prevent movement during transit. Once at the storage facility, steel coils are typically stacked in a secure and organized manner, either on the ground or on specially designed racks. The coils may be stored indoors or outdoors, depending on the specific requirements and conditions. To protect the coils from damage and corrosion, appropriate weather protection measures and coatings are applied.

- Q: benchmade mpr with m390 steel knife. Is it better than d2 s30v or 154cm steel?

- From what I understand m390 is a new steel (at least for benchmade) so there doesn't seem to be a consensus on how it performs. Looking at the table, it should be very corrosion resistant. I'd guess it could be classified as a stainless steel. Sorry I don't have more info for you. EDIT: here's a link from the steel manufacturer. I hope this info helps.

- Q: How are steel coils inspected for impact resistance using impact testers?

- Steel coils are inspected for impact resistance using impact testers, which are specially designed machines used to assess the ability of the steel coils to withstand impacts. The process involves subjecting the steel coils to controlled impacts and measuring the extent of deformation or damage caused by the impact. Firstly, the steel coils are securely placed on the impact tester, ensuring that they are in the correct position and orientation. The impact tester is equipped with a striking element, such as a pendulum or a falling weight, which is designed to deliver a specific amount of force upon impact. The striking element is carefully aligned with the steel coil to ensure accurate and consistent testing. Once everything is set up, the impact tester is activated, and the striking element is released to impact the steel coil. The force of the impact is carefully controlled and measured to ensure consistency across multiple tests. The impact tester records various parameters during the impact, including the force applied and the duration of the impact. After the impact, the steel coil is carefully examined for any visible deformation or damage. This can include checking for dents, cracks, or any other signs of structural compromise. The extent of the deformation or damage is recorded and compared to predetermined acceptance criteria to determine whether the steel coil passes or fails the impact resistance test. Impact testers can be equipped with various sensors and cameras to capture additional data during the testing process. High-speed cameras can be used to record the impact in slow motion, allowing for a detailed analysis of the coil's behavior during the impact. Strain gauges can be attached to the steel coil to measure the strain and stress experienced during the impact. Overall, the use of impact testers provides a reliable and standardized method for inspecting the impact resistance of steel coils. By subjecting the coils to controlled impacts and carefully measuring the extent of deformation or damage, manufacturers can ensure that their steel coils meet the required impact resistance standards for various applications.

- Q: All of my friends say that if a car made of mostly carbon fiber would crash into a full steel car, or vice versa, the steel car would be DESTROYED and the carbon fiber would drive away, if not, easily repairable.

- At a reasonably high speed, both cars would be undrivable. That's by design, not due to the strength/weakness of the materials. The energy in an impact needs to go somewhere. Cars are designed so the body and the frame will bend and break, reducing the impact on the occupants. If the car is too rigid the chances of the occupants being injured increases. Carbon fiber composites do have a better strength to weight ratio than steel but they're also a lot less dense, so the same volume of material will have a similar strength. The primary benefit to carbon fiber is that for a part of the same strength the carbon fiber part will weigh less than the steel part.

- Q: Eutectoid Steel

- Eutectic steel is used to produce pearlite, bainite, spheroidite and martensite steels. Those steels vary in strength, hardness and ductility. One uses martensite steel for example in razor blade manufacturing. Of course there is no end to the various uses of these steels.

- Q: Steel roofing info. Pros and cons on steel roofing?

- Steel roofing Pro...life of product is much longer then Asphalt shingles....Looks great...multi colors.......Just love the stuff... Cons....More costly then singles at first but since it last longer it is really a better buy.......

- Q: What are the different grades of steel used for making coils?

- When making coils, various grades of steel are commonly utilized, depending on specific requirements and applications. Some frequently employed grades are: 1. Mild steel, also referred to as low carbon steel, is often employed for coil production due to its favorable characteristics of formability, weldability, and machinability. It is suitable for diverse applications where strength and durability are not the primary concerns. 2. High carbon steel, which contains elevated carbon levels, offers increased strength and hardness. This grade is commonly used for coils that require high strength and resistance to wear, such as springs and automotive components. 3. Stainless steel, characterized by a high chromium content, exhibits excellent corrosion resistance. Coils made from stainless steel are commonly utilized in applications where resistance to rust and staining is critical, such as kitchen appliances, automotive trim, and medical equipment. 4. Galvanized steel, coated with a layer of zinc, provides exceptional corrosion resistance. Galvanized steel coils find common use in outdoor applications that involve exposure to moisture and other elements, including roofing, fencing, and HVAC ductwork. 5. Electrical steel, specifically designed for electrical applications like transformers, motors, and generators, possesses low impurity levels and is optimized for high magnetic permeability and low core loss. 6. Advanced high-strength steel (AHSS), engineered to offer exceptional strength while maintaining good formability, is frequently employed in the automotive industry. AHSS coils contribute to lightweighting vehicles while ensuring structural integrity and crashworthiness. These examples represent only a fraction of the steel grades employed in coil manufacturing. The choice of a specific grade depends on factors such as the intended application, desired properties, and cost considerations.

- Q: What are the common surface treatments for steel coils?

- The common surface treatments for steel coils include galvanization, which involves coating the steel with a layer of zinc to protect against corrosion, as well as painting or powder coating to provide additional protection and enhance aesthetics.

- Q: How can I owe a Pre-engineered Steel Building?

- You just have to do small efforts for owing a steel building: Firstly you have to finalize a steel building company for construction work. After finalizing the steel building company, the next step is the paperwork - the agreements and contracts. Some steel building companies may also ask for a verbal approval for the factories to get the work started.

- Q: Search the internet for 'Frost Clipper Knife'. This knife comes in either stainless or carbon steel. I have a friend who has one (stainless steel) and he is very impressed with it, but I have heard that Carbon Steel blades are better? Discuss...

- If your talking about a folding pocket knife, I think that it's basically six one way and a half dozen the other. I actually do prefer stainless for my pocket knives. I don't want to oil a knife to the degree I feel carbon requires, only to then stick it my pocket to attract dirt to the knife and oil to my pants. I'm the exact opposite on sheath knives though. I like 1095 carbon steel, plain edge sheath knives. I'll thrash on them HARD, and I rarely have major edge problems. Of course, I require them to be coated with some kind of powder coat or the like, because they can rust, but I do try and keep them clean and dry when in the sheath, so they won't pit the uncoated edge. My reasons for this sheath knife preference is multi-fold. First, these knives are simply affordable. I don't spend $80 dollars on a outdoors sheath knife. I use the tool too hard to want to spend more. I don't like the more traditional stainless steels such as AUS-8, 420HC, and 440C (not to mention the HORRENDOUS 440A) because I feel that the all else being equal, a stainless blade will bend before a carbon blade will break. I also think that carbon holds an edge at least as well, if not better, than traditional stainless, and it's much easier to hone. I don't know much about these new laminates, other than the very hard, but not so tough. They seem to be POSSIBLY too brittle for my use. That, combined with the fact that they cost a FORTUNE, means that I just won't be considering them.

Send your message to us

Chinese Best Cold Rolled Steel Coil -Excellent Process Capability

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords