China top quality ISO2531 cement lined class K9 DN80 ductile cast iron DCI pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

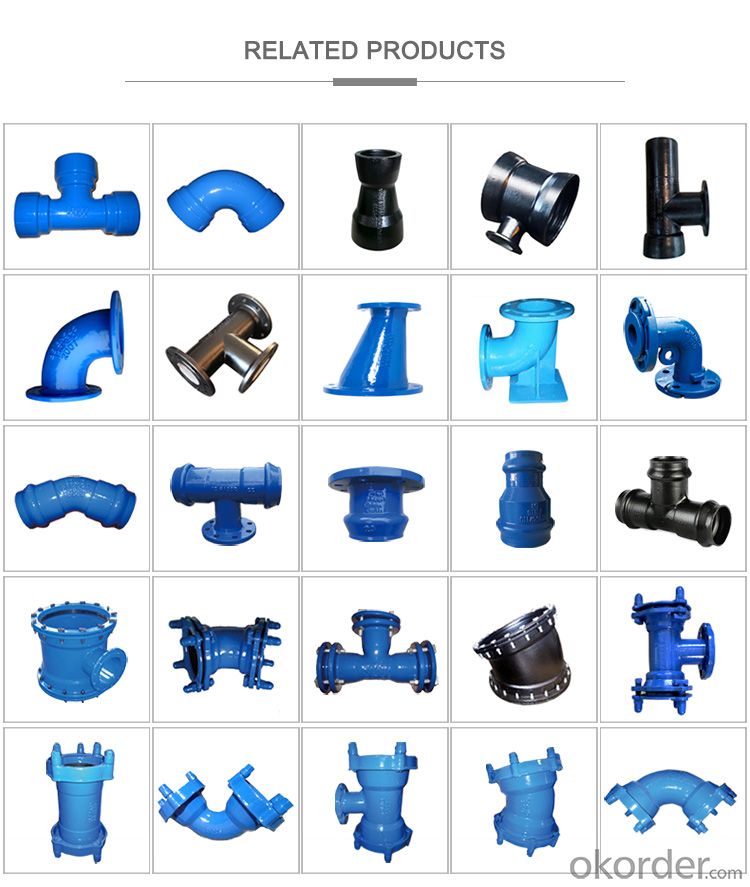

You Might Also Like

Specification

Type:

T-type Joint Pipe (Push-on)

Standard:

ISO2531

Material:

ductile iron ggg50

Pressure:

PN10, PN16, PN25,PN40

Wall Thickness:

K9, K8, C25, C30, C40

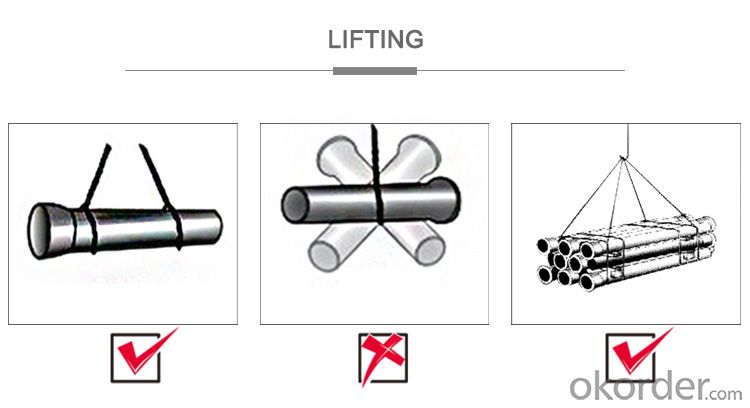

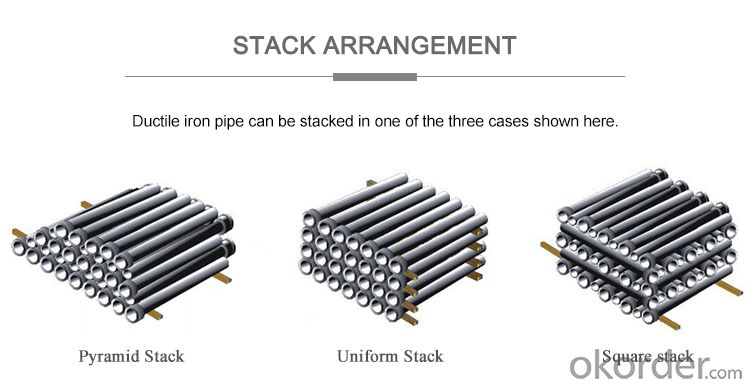

Packaging:

Bundle, in bulk

Yield (≥ MPa):

300MPa

Hardness:

≤230HB

Pull Strength:

≥420MPa

Processing Service:

Casting

Color:

Black, red, blue or as requested

Length:

6m, cut to 5.7m

China top quality ISO2531 cement lined class K9 DN80 ductile cast iron DCI pipe

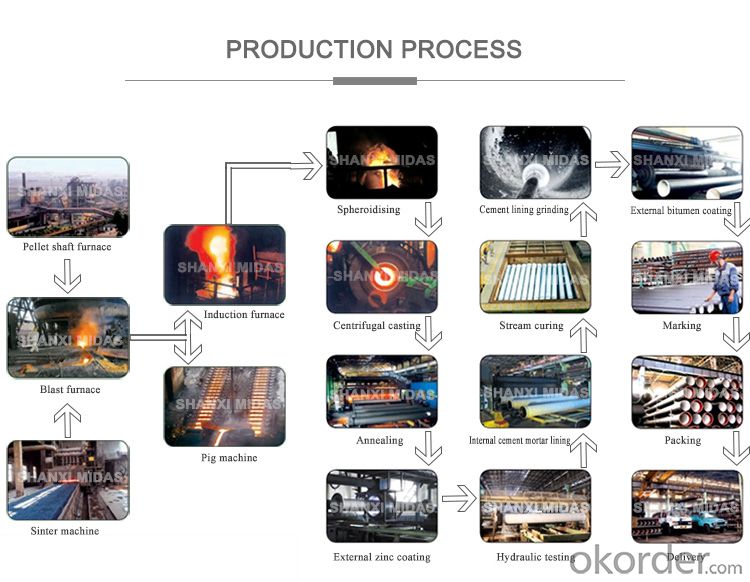

The T-type Joint Pipes (Push-on) produced by our company range from DN80mm to DN2600mm are flexibly jointed with sockets and spigots; they are the first choice in urban water pipe networks due to their convenient installation, strong seismic performances, seal ability and corrosion resistance.

Specifications

| Type | T-type Joint Pipe (Push-on) |

| Standard | ISO2531, EN545, EN598, etc |

| DN | DN80mm~DN2600mm |

| Material | Ductile Cast Iron GGG50 |

| Pressure | PN10, PN16, PN25,PN40 |

| Wall thickness | K9, K8, C25, C30, C40 |

| Length | 6m, cut to 5.7m |

| Application | Water supply project, drainage, irrigation, water pipeline system. |

| Internal Coating | a). Portland cement mortar lining |

| b). Sulphate Resistant cement mortar lining | |

| c). High-Aluminum cement mortar lining | |

| d). Fusion bonded epoxy coating | |

| e). Liquid epoxy painting | |

| f). Black bitumen painting | |

| External Coating | a). zinc+bitumen(70microns) painting |

| b). Fusion bonded epoxy coating | |

| c). Zinc-aluminum alloy +liquid epoxy painting | |

| Package | Bundles, in bulk |

| Note | The coating can also be accordance with customers' requirements. |

Product Images

- Q: Ways of connecting ductile iron pipes

- Ductile iron pipes are all made of flexible interfaces.

- Q: Ductile cast iron can replace copper sleeve

- Under dry friction conditions, we design a pre - formed synovial membrane on the surface of the bearing to ensure that the solid lubricant is transferred to the dual parts in the shortest possible time, and an effective solid lubricant film is formed

- Q: What are the different types of restrained joints for ductile iron pipe?

- Some of the different types of restrained joints for ductile iron pipe include mechanical joints, push-on joints, and restrained push-on joints. Mechanical joints use bolts and gaskets to create a tight seal, while push-on joints rely on a rubber gasket to provide a secure connection. Restrained push-on joints incorporate additional features such as external restraints or wedges to prevent pipe movement.

- Q: What is the expected service life of ductile iron pipe?

- The expected service life of ductile iron pipe can vary depending on various factors such as the environment, soil conditions, water quality, and the level of maintenance and corrosion protection measures implemented. However, on average, ductile iron pipe is designed to have a service life of 75 to 100 years. This is due to its superior strength, durability, and resistance to corrosion. Ductile iron pipe is known for its ability to withstand harsh conditions and has been used extensively in water and wastewater systems, industrial applications, and other infrastructure projects. Regular maintenance and proper corrosion protection can further extend the service life of ductile iron pipe, ensuring its continued reliability and performance over many decades.

- Q: What's the function of the cement mortar lining of ductile iron pipes?

- You may easily say that this statement is vague and there is no evidence that other manufacturers often do so when promoting other types of lining. However, in order to prove the truth of the above view, we have compiled sufficient examples to demonstrate the reliability of each of these statements from a scientific and logical point of view.We have stated each of these fields and other embedded systems as specious statements. There is only a reasonable conclusion that the cement mortar lining (CML) provides excellent protection for ductile iron pipes and steel tubes.Ductile iron pipe and steel pipe CML CML produces a synergistic effect of the incomparable.

- Q: How are ductile iron pipes joined to fittings and valves?

- Fittings and valves are commonly connected to ductile iron pipes using either flanged connections or mechanical joints. Flanged connections involve the use of circular discs called flanges, which have evenly spaced holes around the edge. These flanges are bolted together to create a tight seal between the pipe and the fitting or valve. To connect a ductile iron pipe to a fitting or valve using a flanged connection, the pipe end is first prepared by cleaning and removing any rough edges. Then, a gasket made of rubber or another suitable material is placed between the pipe end and the flange face. The flange is aligned with the pipe, and bolts are inserted through the holes in the flange, passing through corresponding holes in the fitting or valve. Once all the bolts are in place, they are tightened evenly, gradually applying pressure to compress the gasket and create a secure, leak-proof seal. To ensure proper alignment and sealing, the bolts are typically tightened in a specific pattern or sequence. Alternatively, mechanical joints can be used to join ductile iron pipes to fittings and valves. This involves inserting a rubber gasket or gland into a groove on the pipe end. The fitting or valve also has a corresponding groove, and when the two are brought together, the gasket is compressed to create a tight seal. Mechanical joints offer some flexibility, allowing for slight movement or expansion and contraction of the pipe. This is beneficial in applications where there may be thermal variations or ground movement, as it reduces the risk of pipe failure. Both flanged connections and mechanical joints are widely used in various industries and applications that require the connection of ductile iron pipes to fittings and valves. The choice of joining method depends on factors such as the specific application, pipe size, pressure requirements, and local codes and regulations.

- Q: Can ductile iron pipes be used for conveying gases?

- Yes, ductile iron pipes can be used for conveying gases. Ductile iron is a strong and durable material that can withstand high pressure and temperature variations, making it suitable for transporting gases. Additionally, ductile iron pipes have excellent corrosion resistance, which is important when dealing with potentially corrosive gases. However, it is crucial to ensure that the specific type of gas being conveyed is compatible with ductile iron to prevent any chemical reactions or damage to the pipes. Proper engineering design and material selection should be considered to ensure the safe and efficient conveyance of gases through ductile iron pipes.

- Q: Can ductile iron pipes be used for gas distribution systems?

- Yes, ductile iron pipes can be used for gas distribution systems. Ductile iron pipes are known for their strength and durability, making them suitable for carrying various types of fluids, including natural gas. These pipes have excellent corrosion resistance and can withstand the high pressure and stress typically associated with gas distribution systems. Additionally, ductile iron pipes are cost-effective and have a long lifespan, making them a reliable choice for gas distribution networks.

- Q: Is the water cast iron pipe 100% for hydrostatic test?

- Domestic manufacturers, such as steel group wing ductile iron pipe limited liability company, Xinxing Ductile iron pipes, Saint Gobain pipe is 100% factory test pressure, test pressure in 3.2-5.0MPa according to different specifications.

- Q: Are ductile iron pipes suitable for water distribution networks?

- Yes, ductile iron pipes are highly suitable for water distribution networks. They possess excellent strength, durability, and corrosion resistance, making them ideal for carrying and delivering water over long distances. Additionally, their flexibility allows for easy installation and adaptability to various terrains, ensuring reliable and efficient water distribution.

Send your message to us

China top quality ISO2531 cement lined class K9 DN80 ductile cast iron DCI pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords