China Supplier of Sublimation Heat Transfer Machine with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1000 Sets Per Year set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Detailed Product Description

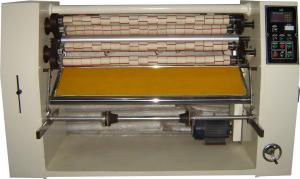

Sublimation Heat Transfer Machine

1. Professional supplier, quality guarantee

2. Easy to operate, solid structure

China Supplier of Sublimation Heat Transfer Machine with Best Price

Sublimation Heat Transfer Machine:

Mug Sublimation Heat Transfer Machine / Plate Sublimation Heat Transfer Machine / Cap Sublimation Heat Transfer Machine / Combo Sublimation Heat Transfer Machine.

- Q: Heat conduction oil furnace with coal or electricity?

- Electricity heat conduction oil furnace more economic and environmental protection, electric power can be adjusted by the use of heat conduction oil furnace, heating efficiency, save energy and reduce the cost, no pollution and environmental protection.

- Q: Use finned tube condenser and evaporator, its fin spacing of how to choose

- Example 3: steam generator, the tube is the boiling water, flue gas pipe outside, fin should add in the flue gas side. When, should be paid attention to in the design, should as far as possible on the side of the heat transfer coefficient of the tube, in order to add fin. (2) such as pipe on both sides of the heat transfer coefficient is very small, in order to strengthen heat transfer, should be in both at the same time adding fin, if there is difficulties, on the structure, both sides are without fin. In this case, if only on one side and fin, the increase of heat transfer is not have obvious effect. Case 1: the traditional tubular air preheater, air tube go, flue gas pipe outside. Because is gas for gas heat exchanger, on both sides of the heat transfer coefficient is very low, the tube and fin and difficult, have to light tube. Example 2: heat pipe air preheater, although is still a flue gas heating the air, but because of the flue gas and air are outside the pipe flow, so the flue gas side and air side can be conveniently used finned tube, the heat transfer is greatly increased. (3) if the tubes on either side of the heat transfer coefficient is large, it is not necessary to adopt finned tube. Case 1: water/water heat exchanger, heat cold water with hot water, on both sides of the heat transfer coefficient is high enough, there is no need to use the finned tube. But in order to further enhance the heat transfer, can use threaded pipe or corrugated pipe instead of light. Example 2: power plant, the condenser tube is water vapor condensation, the tube water. On both sides of the heat transfer coefficient is very high, in general, without using finned tube.

- Q: What is the working principle of heat pipe

- Heat pipe is a kind of high heat conduction performance of the heat transfer element, it through the closed tube shell substance in evaporation and condensation heat transfer, high thermal conductivity, excellent isothermal property, heat transfer area on either side of the hot and cold can be arbitrary change, heat transfer and temperature can be controlled and a series of advantages over a long distance. Made up of heat pipe heat pipe heat exchanger has high heat transfer efficiency, compact structure, small fluid resistance loss, is helpful to control the dew point corrosion, etc.

- Q: Industrial common heat transfer (heat transfer

- Heat conduction heat convection heat radiation, heat convection is divided into: natural convection and forced convection

- Q: Heat exchanger is what to do, have what use?

- Heat exchanger is refers to two different temperatures of fluid for heat exchange equipment. Heat exchanger heat transfer equipment is widely used in energy consumption as a large area. With the rapid development of energy-saving technology, more and more kinds of heat exchanger. Suitable for different medium, different conditions, different temperature and different pressure heat exchanger, structure is different also

- Q: how to prevent

- Scale compared to metal, is a poor conductor of heat, can reduce the heat transfer efficiency.

- Q: Now with wire mesh and steel net two kinds of choices, but the screen is the question of silicone coated on the surface it is difficult to clean, please answer

- We also encountered such a problem, we use fixed plate glass, see the stencil is not ideal. Our steel mesh on loud, is to provide the infineon opening files. I don't know how do you do?

- Q: What is heat transfer, heat transfer is wha

- Each point within the object or system, the temperature difference between heat conduction is the necessary condition. Caused by heat conduction heat transfer rate (hereinafter referred to as thermal conductive rate) is determined by the distribution of temperature within the object. Temperature field is as a flash object or the total temperature distribution of each point in the system.

- Q: The types of heat exchangers have?

- ?the classification of the non-metallic materials heat exchanger (1) graphite heat exchanger (2) the fluorine plastic heat exchanger (3) ceramic fiber composite heat exchanger (4) glass steel heat exchanger

- Q: Which is better for heat exchange equipment

- Thermal conductivity? Is the thermal conductivity copper effect will be better

As a leading manufacturer, all Microtec products are fully assembled by our state of the art manufacturing facility prior to shipment and released only after extensive testing and inspection by our qualified technicians, maintaining the strictest quality control procedures.Our mission is to be a world supplier of Heat Transfer Products and Consumables. We are committed to the principal of satisfying customer and market demands, pursing scientific administration and superior quality by using the latest technology grounded in a thorough understanding of the end-user's needs.

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2007 |

| Annual Output Value | |

| Main Markets | 7.69% North America 7.69% South America 7.69% Eastern Europe 7.69% Southeast Asia 7.69% Africa 7.69% Oceania 7.69% Eastern Asia 7.69% Western Europe 7.69% Central America 7.69% Northern Europe 7.69% Southern Europe 7.69% South Asia |

| Company Certifications | ISO 9001:2008;SGS; CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen,Guangzhou,Zhuhai |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

China Supplier of Sublimation Heat Transfer Machine with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1000 Sets Per Year set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords