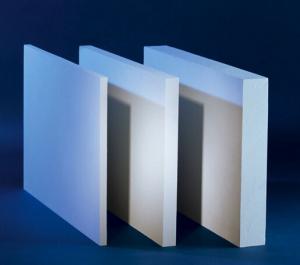

Ceramic Fiber Board with Alumina Plates and Disks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Application: | Liners Of Industrial Furnace | Thickness: | 6~80mm | Width: | 1000mm/600mm |

| Length: | 1200mm/1000mm | Grade: | ST (Standard) | Chemical Composition: | AL2O3:52-55% |

| Ultimate Strength (≥ MPa): | 0.5Mpa | Working Temperature: | 1200C | Fiber Diameter: | 3-5um |

| Thermal Conductivity: | 0.085-0.180w/m.k(400-1000... | Shrinkage (1800℉, 3h): | -3(24hours) | Place of Origin: | (Mainland) |

| Model Number: | FQ9- | Brand Name: |

Packaging & Delivery

| Packaging Detail: | Inside plastic bag.Outside carton box. 25mm 4pc/carton. 50mm 2pc/carton Big Package;8 cartons/pallet |

| Delivery Detail: | 15DAYS |

Specifications

Ceramic fiber manufacturer

Low thermal storage

Fire protection & Corrosion resistance

Long service life

Ceramic Fiber Board of 4 grades including standard, high pure, high

aluminium and zirconium adopt corresponding ceramic fiber bulk as raw material, vacuum

forming technology and dry process via drying machine guarantee our Ceramic Fiber

Board possesses delicate work. The 4 grades Ceramic Fiber Board also has close texture,

good tenacity, high intensity and anti wind-erosion nature except all the excellent

properties owned by Ceramic Fiber Bulk. We mainly export to UK, USA, GERMANY, ITALY TURKEY. The MIDDLE EAST , AFRICA etc.

Characteristic:

low thermal conductivity , low thermal capacity

High thermal stability ,resistance to thermal shock,flame and airflow attack

Resistance to corrosion,high compressive strength.

High toughness,easy to cut and install quickly

Accurate thickness and size

Application:

Available in the fields that require toughness , self-supporting and insulation ,with a good performance against mechanical damage

Furnace construction: high-temperature, insulation lining for a variety of industrial furnaces, such as pushed slab furnaces, ladle furnaces, bell-type furnaces, tunnel kilns, roller kilns, aluminium melting furnaces, heat treatment furnaces. Masonry insulation layer. The kiln liner, kiln cars, door baffles of high-temperature furnaces, furnace temperature divider plates. High-temperature thermal- block plate

Tech data:

Standard | High Pure | High Aluminum | Zirconium | ||

Classifition temperature(oC) | 1260 | 1260 | 1360 | 1430 | |

Work temperature(oC) | 1050 | 1100 | 1200 | 1350 | |

Color | Pure white | Pure white | Pure white | Pure white | |

Density(kg/m3) | 280 | 280 | 280 | 280 | |

480 | 480 | 480 | 480 | ||

Permanent linear shrinkage(%) (after24hours,density320kg/m3) | -3 | -3 | -3 | -3 | |

(1000oC) | (1100oC) | (1200oC) | (1350oC) | ||

Thermalconductivity(w/m.k) density285kg/m3) | 0.085(400oC) | 0.085(400oC) | 0.085(400oC) | 0.085(400oC) | |

0.132(800oC) | 0.132(800oC) | 0.132(800oC) | 0.132(800oC) | ||

0.180(1000oC) | 0.180(1000oC) | 0.180(1000oC) | 0.180(1000oC) | ||

Compressive strength (Mpa) (thermal shrinkage 10%) | 0.5 | 0.5 | 0.5 | 0.5 | |

Chemical composition (%) | AL2O3 | 46 | 47-49 | 52-55 | 39-40 |

AL2O3+SIO2 | 97 | 99 | 99 | - | |

AL2O3+SIO2+Zro2 | - | - | - | 99 | |

Zro2 | - | - | - | 15-17 | |

Fe2O3 | <1.0 | 0.2 | 0.2 | 0.2 | |

Na2O+K2O | ≤0.5 | 0.2 | 0.2 | 0.2 | |

Size (mm) | 1200x1000; 1200x600; 1000X1000, 900x600; 600x300 | ||||

Thickness | 6-80mm | ||||

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- Fiber board thermal conductivity of ceramic fiber board thermal conductivity information is mainly: ceramic fiber board thermal conductivity, thermal conductivity of ceramic fiber board price, thermal conductivity of ceramic fiber board wholesale, thermal conductivity of ceramic fiber board factory, discusses the protection method of hot plate test principle and method of MDF thermal conductivity and its relation with temperature; and analyzed the test error.

- Q: What are the standards for ceramic fiber boards?

- Ceramic fiber board currently only GB, and many production enterprises are also in accordance with GB to perform.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board density in conventional 300-350Kg/m over 350Kg/m to fand, fand fireproof plate series.

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- The biggest difference between the two is that:1, the coefficient of thermal conductivity is different, the nano ceramic plate is about three times of the ordinary ceramic fiber board2, temperature class is not the same, nano ceramic board maximum temperature of 1050 degrees, ceramic fiber board should be 1400 degrees temperature.3, the range of applications is different. Nano ceramic plate is mainly used in high, fine and sharp technical fields, and has strict requirements on thermal conductivity. Ceramic fiber boards are widely used and can be used wherever there is flame or temperature.

- Q: What are the uses of ceramic fiber boards?

- The ceramic fiber board, also called aluminum silicate fiber board or refractory fiber board, is divided into five grades according to the temperature grade:Fire dragon type ceramic fiber board HLGX-164Fire dragon standard ceramic fiber board HLGX-264Fire dragon high purity ceramic fiber board HLGX-364The dragon of high alumina ceramic fiber board HLGX-464Fire dragon contains zirconium type ceramic fiber board HLGX-564

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Distinguishing.Ceramic silicon fiber board by long fiber silica, clay, talc, glaze etc. after 1150 degrees high temperature sintering, twenty-first Century revolutionary high-tech building materials. Characteristics: flexibility, high toughness, high strength, anti wind pressure; with homogeneous magnetized light ceramic surface, disposable, pores, anti pollution, is not easy to dust, mildew, antibacterial, deodorant, anti slip, no static, not fear of chemical erosion, such as acid, alkali, or even sulfate; fire, smoke, high temperature resistance, easy processing, cutting a hole.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board divided by density, can be divided into ceramic fiber, ceramic fiber board density 250-260Kg/m fand; density, fand 300-350Kg/m;

Send your message to us

Ceramic Fiber Board with Alumina Plates and Disks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords