Carrier Roller,Baffel Roller, Taper Roller, Comb-Type Roller, Embossing Roller, Friction Roller

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

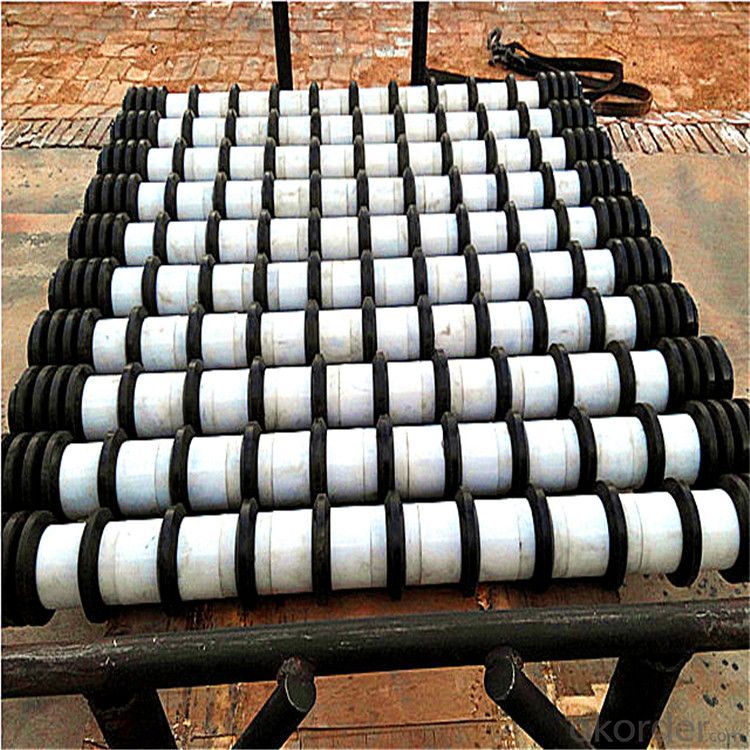

As an important component of belt conveyor, the carrier roller can effectively support the the belt conveyor and the materials on the conveyor belt and ensure that the belt conveyor will be in normal operation. According to GB/T10595 regulation, the carrier roller diameter shall be divided into:Φ76, Φ89, Φ108, Φ133, Φ159, Φ194, Φ219 and so on. In general, the roller diameter shall be selected according to the belt width, speed and other parameters. However, the length of carrier roller shall depend on the conveyor belt width and supporting roller form. The carrier roller bearing shall be selected according to the bearing capacity of the single roller and service life of bearing.

Performance Features

When the non-contact labyrinth seal is applied, the sealing channel length shall be 60~80mm; It has a favorable waterproof and dust proof performance.

Considering that the big clearance (C4) deep groove ball is applied, the bearing can be operated flexibly when the axis bending deflection is less than 12.In the meanwhile, please apply the two-sealing bearing (ZZ) to enhance the waterproof and dust proof performance.

The steel pipe which is manufactured by domestic well-known steel pipe plant for the carrier roller is applied to serve as the roller skin. However, its radial jump, ovality, straightness, other tolerance and appearance indexes shall satisfy the high-precision products requirements as specified in GB/T13973.

The bearing seats is manufactured by applying the high-quality cold-rolled steel sheet(material:08AL). Considering that the bearing seat is pressed in the pipe in interference way. It can reduce the welding deformation, guarantee the coaxiality between the bearing on both ends of carrier roller, reduce the rotational resistance of carrier roller, avoid the stress concentration when the seam allowance is processed and produced, as well as increase the service life of carrier roller.

It has excellent mechanical performance and rotational resistance factor of equal to or less than 0.022. Therefore, its service life can last for more than 50,000 hours, higher than the 20,000 hours as specified in GT/T10595。

Buffer roller

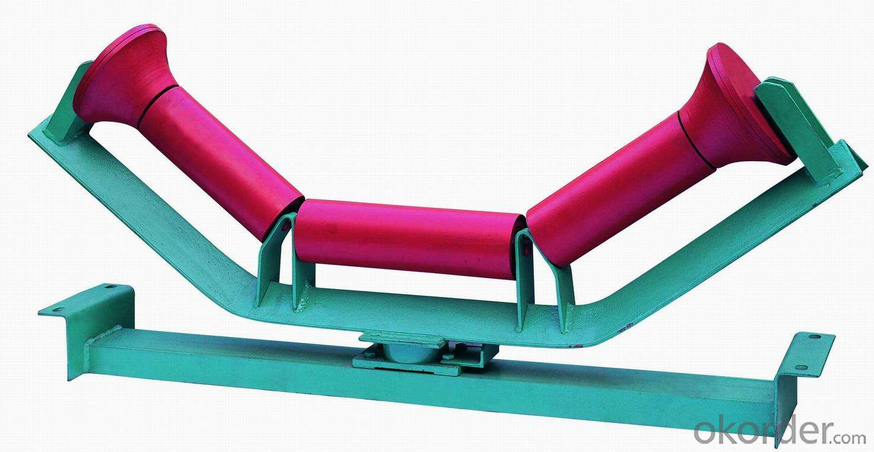

Buffer roller is a kind of common carrier idler that it is covered with a certain layer of rubber in the surface. It is mainly used in the bottom section of feed channel, which can absorb the impacting kinetic energy to the adhesive belt that causes by dropped materials during it is transported. It can prolong the service life of the belt of conveyor. The sets of buffer rollers has 30°,35°,45°.Groove-type rubber-ring buffer roller. In line with the bulk density, lumpiness and the height of blank, the distance among carrier rollers can be decided. Generally speaking, the space among the carrier roller is 1/2-1/3. When it transports the bigger bulk density materials and higher drop, it can adopts 1.2-1.5 times diameter of carrier roller. The diameter range of this series of carrier rollers are φ76-φ219. Range of length is 160-1120.

General carrier roller

The carrier roller refers to the smooth roll, which is the part to bear the conveyor and carried materials. Mainly, it is used in troughed idler, transition idler, paralleling upper supporting roller and others. Generally, the standard groove angle contains 0°、10°、20°、30°、35°、45°. The trough type carrier roller is divided into two pattern, standard type and proclined type. The standard type is mainly used in common ad reversible running conveyor. The prolined type is used to procline 1.5°toward the running direction of side roller of the troughed carrier roller. It has the great function of offset adjustment. It is mainly used in one-way traveling. Generally, it is used in the all line. It is not necessary that it can equipped with self-aligning carrier roller sets. Diameter range of this series of carrier roller is φ76-φ219. Range of length is 160-1120.

Friction carrier roller

The friction carrier roller is made up of common roller and circle friction gear. It has two structures, such as single friction wheel and dual friction wheel, which mainly uses to adjust the off tracking of the conveyor. The friction is mainly used in return friction self-aligning idler and carrier friction self-aligning idler. By means of the spinning of the transmission shaft unit in the middle, the self-aligning can correct the excessive off tracking during the operation of the belt conveyor. No matter which direction the conveyor is off tracking, the same directional roller will rotate along with the moving direction of adhesive belt, which can correct the off-tracking conveyor. Thus, it can ensure that the belt conveyor can run normally.

Comb Carrier Roller

Comb Carrier Roller is an ordinary light roller, which is covered with comb circle and isolating sleeve, it has cleaning effect on conveyor belt. Comb-Shaped Carrier Roller group is mainly used in the occasions where the material is bonded seriously. It can remove the sticky material attached to the conveyor belt, keep the belt clean, and has the function of running smoothly and preventing the deviation. Comb-Shaped Carrier Roller is often used in conjunction with the screw roller, mainly used at the starting point of the return belt. The series roller has a diameter range of φ76-φ219 and length of 465-3350.

Screw Roller

Screw Roller is an ordinary light roller, which is covered with left and right spiral parts twined spot welding round bar steel, it has cleaning effect on conveyor belt. Screw roller group is mainly used in the occasions where the material is bonded seriously. It can remove the sticky material attached to the conveyor belt, keep the belt clean, and has the function of running smoothly and preventing the deviation. Screw Roller is often used in conjunction with the Comb-Shaped Carrier Roller, mainly used at the starting point of the return belt. The series roller has a diameter range of φ76-φ219 and length of 500-3350.

Cone Roller

The roller skin of the Cone Roller is a conical structure with small outer and big inner, which is mainly used to automatically adjust the deviation of the conveyor belt. The same as the self-aligning roller, it mainly depends on the rotating shaft assembly of both sides of the roller to automatically correct the excessive deviation of the conveyor belt in the operation process, so that the belt deviation can be corrected to ensure the normal operation of the conveyor. The smaller end diameter range of the series roller is φ89-φ133, and the bigger end diameter is φ108-φ219. The length range is 315-980.

- Q: What does the general machine manufacturing include?

- General machinery manufacturing basic courses include: mechanical drawing, metal technology, electrical and electronic technology, theoretical mechanics, mechanics of materials, mechanical principle, mechanical parts, mechanical CAD, metal cutting machine design, metal cutting principle and tool design, manufacturing process and fixture design, CNC machine tools. Design and manufacture of machinery design and manufacture ability can use professional knowledge of machinery and equipment and industrial equipment.

- Q: Is the general machinery manufacturing industry the same as the general equipment manufacturing industry?

- The general machinery manufacturing industry includes welding, casting, forging, machining, forging, heat treatment, etc..General purpose equipment is relative to special equipment.

- Q: Connect to the logistics pipeline can not transport goods?. Is it because the colors don't match? What are the colors of the configuration page of the machine?

- Have the Redstone engine drive, the logistics pipeline can transport, Redstone engine to drive rod drive, after the engine will push and pull, the logistics pipeline to connect the box box [at the end of the shadow box or other storage, except for the adoption of], the input should be put in the engine Redstone pipeline, a pipeline cannot import or export goods back and forth.

- Q: Introduction of Hefei General Machinery Research Institute

- Hefei General Machinery Research Institute was renamed as General Machinery Research Institute of China in November 20, 2010. Hefei General Machinery Research Institute (formerly Hefei General Machinery Research Institute) is a multi - professional and comprehensive national and scientific research institute directly under the China National Machinery Industry Corp.

- Q: Business license written in the scope of business is engaged in general machinery and accessories sales, self-employed and agents of all types of imports and exports, we export printing equipment?

- That one can, the same kindAskCan we also export fire hoses, CNC machines and pet feeds? Is the drawback OK?Chasing the answerPet feed is no good,

- Q: Introduction to general machinery

- Dedicated to the hot issues in the dissemination of new ideas and new technology and new technology industry report concerned, progress tracking of national key engineering projects, provide dynamic information industry the most efficient, is the expert reader general machinery manufacture and use of the Department of engineering and technical personnel and management personnel.

- Q: What are the general mechanical bearings?

- Deep groove ball bearings, self-aligning ball bearings, cylindrical roller bearings, tapered roller bearings, angular contact ball bearings,

- Q: This is my 2 major. Why is my classmate only mechanical design, manufacture and automation without general mechanical direction?

- Choose professional ah, this profession now, very good, need two times to work hard, the future is good. Mechanical well, which is the general machinery;, is of course the popularization of machinery;

- Q: What about Hefei General Machinery Research Institute?

- That's not necessarily true. There must be some kind of care. And as I said, people in the feeling is very deep, because the house moved from Beijing to Hefei, we basically know, so there is a difficulty in what will certainly help, after all, here is a small village, just look at it this way.

- Q: State-owned enterprises? Or research institutes? Or something else?

- Mechanical department directly under a national comprehensive scientific research institute, mainly engaged in petroleum, chemical industry, energy, metallurgy, gas, environmental protection, national defense and military industry, general machinery, chemical equipment design and development, product development, project contracting, equipment, testing equipment and supervision etc..

Send your message to us

Carrier Roller,Baffel Roller, Taper Roller, Comb-Type Roller, Embossing Roller, Friction Roller

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords