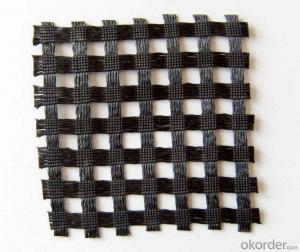

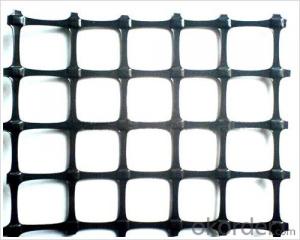

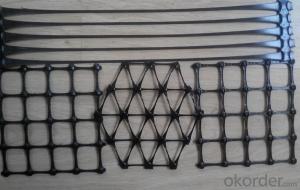

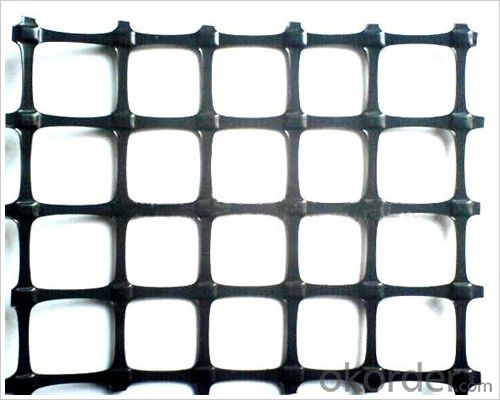

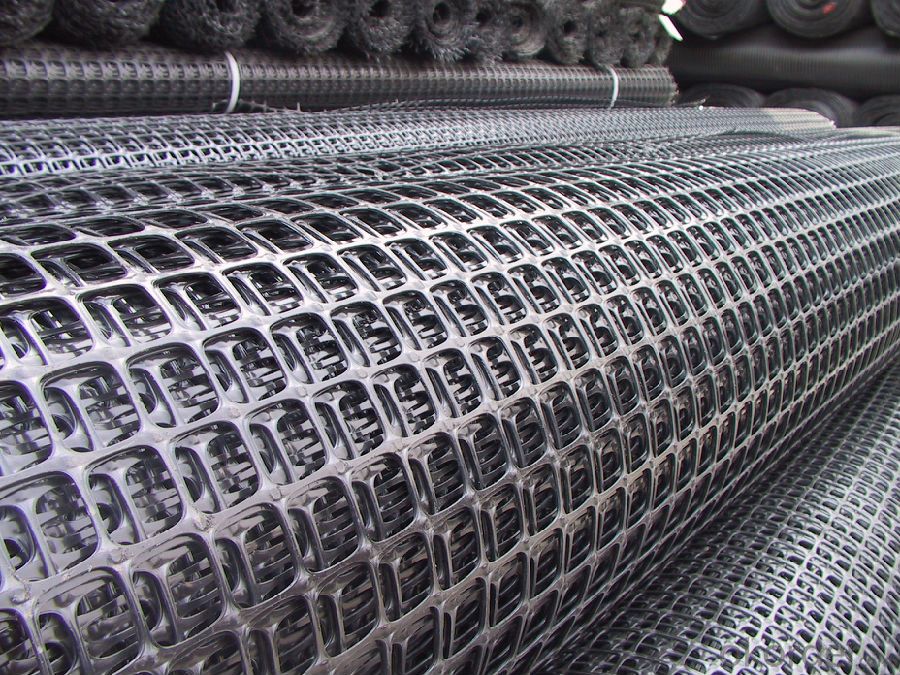

Geogrids for Tree Protection - BX Tensile Strength Biaxial Plastic Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

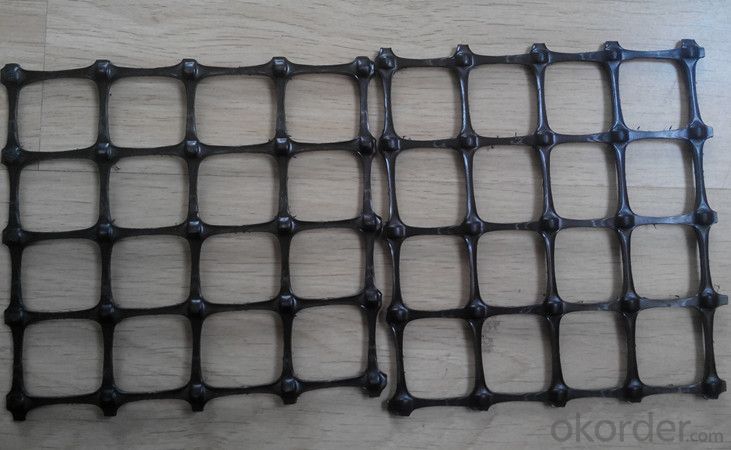

Applications:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

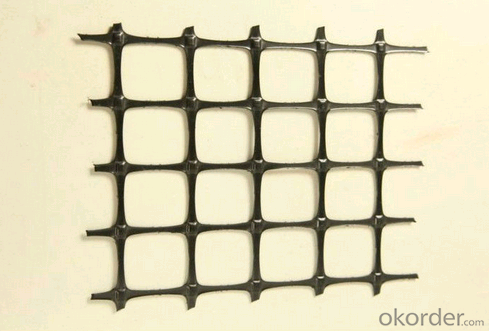

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

| Packaging Details: | according to your need |

| Delivery Detail: | 7days |

FAQ

Q:Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q:What is your minimum order quantity?

A:The minimum order is negotiable.

Q:What is your payment terms?

A: T/T or L/C

Q: What is your delivery time?

A:Production time usually cost 7-15 days.

Q: Why we choose you?

We have up to 15 years experience of geogrid manufacture. best quality of product is guaranteed!

- Q: What are the factors that influence the design and selection of geogrids for reinforcement?

- The factors that influence the design and selection of geogrids for reinforcement include the type and properties of the soil, the load and traffic conditions, the desired level of reinforcement, the project lifespan, the installation and construction method, and the environmental conditions.

- Q: What is a one-way plastic geogrid

- Uniaxial plastic geogrid is a high strength geosynthetics, with high density polyethylene (HDPE) as raw materials, pressure into a sheet by extrusion and punching network rules, and then the longitudinal stretch into the geogrid, widely used in dam, tunnel, highway, railway, port, construction etc. field

- Q: What are the physical properties of Geosynthetics

- 2, the quality of unit area: the quality of the unit area of the unit area of geosynthetics. It reflects the properties of materials in many aspects, such as tensile strength, bursting strength and mechanical properties such as porosity, permeability and hydraulic performance, usually expressed as g / m2, is one of the important physical properties of geosynthetics. The quality of geotextile and geomembrane per unit area is affected by the density of raw materials, and the influence of thickness, admixture and water content. The commonly used geotextile fabric area quality is generally in the range of 50 ~ 1200g / m2

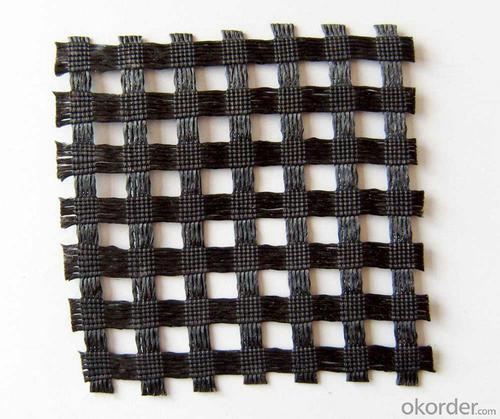

- Q: What is the difference between a woven and a non-woven geogrid?

- A woven geogrid is made by weaving polyester or polypropylene yarns together, creating a strong and stable grid structure. On the other hand, a non-woven geogrid is made by bonding polyester or polypropylene fibers together, forming a random network of filaments. This results in different characteristics and performance. Woven geogrids typically have higher tensile strength and are more rigid, making them suitable for applications requiring load distribution and soil reinforcement. Non-woven geogrids, while generally having lower tensile strength, offer excellent filtration and separation capabilities, making them ideal for erosion control, drainage, and subgrade stabilization.

- Q: Can geogrids be used in green roof applications?

- Yes, geogrids can be used in green roof applications. Geogrids provide reinforcement and stability to the green roof system, helping to prevent soil erosion and retain water. They can help distribute the load of the green roof evenly, ensuring structural integrity and longevity.

- Q: How to restore the plastic geogrid after being destroyed?

- 3 when laying geosynthetics, the direction of high strength should be placed in the main stress direction of the embankment.4 geosynthetic materials should be paved after the design requirements of the back section, and timely coverage with sand.

- Q: How to do a good job ah? How to start the sale of geotechnical materials

- It is a composite geomembrane. The production for the anti-seepage treatment of water conservancy and hydropower, highway, railway, generally two or three layers, a film of a film or a cloth cloth two, the cloth is polyester filament geotextile membrane, generally polyethylene geomembrane, a polyethylene particles blowing or calendering production of plastic film composite filament soil fabric, composite film than general strength more requirements are higher, the typical project is "using the specified diversion project. Specification is 150/0.3mm/150, weight requirements of more than 576g/ g /, stronger than 14kn/m, CBR greater than 2.8KN.

- Q: Where is the best geogrid to do?

- Plastic grille mold Huangyan Xuan Ya mold to do very good, the price is also very suitable!

- Q: What are the differences between geogrids and geonets?

- Geogrids and geonets are both geosynthetic materials used in civil engineering and construction, but they serve different purposes. Geogrids are typically used for soil reinforcement and stabilization, providing tensile strength to improve the stability of soil structures. On the other hand, geonets are primarily used for drainage applications, allowing the flow of water while retaining soil particles. In summary, geogrids enhance soil stability, while geonets aid in drainage.

- Q: How long do geogrids typically last?

- Geogrids typically have a lifespan ranging from 20 to 75 years, depending on various factors such as the quality of the material, environmental conditions, and the level of stress they are subjected to.

Send your message to us

Geogrids for Tree Protection - BX Tensile Strength Biaxial Plastic Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords