Butterfly Valve with Good Quality with Plastic Handle

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

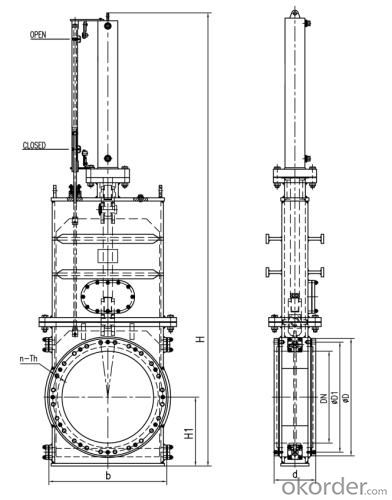

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: Where is the Shandong valve? How about joint valves in Shandong?

- Shandong valve factory is not much, but I know there is a good valve in Shandong area is doing the best, you can Baidu search Shandong valve factory in Shandong united, they do Weifang, the quality of the valve is good, the price is not high, I was with the valve dealer customers are from there I can purchase online, Baidu their company name Shandong valve contact him specific you

- Q: What's the meaning of the "single valve"?

- So called" screwed joint"Valve single order, refers to the valve with a live joint, is a more convenient valve assembly and disassembly.

- Q: What does valve J41H-16C mean?

- J- stop valve4- flange type connection1- structure typeH- alloy steel seal16- nominal pressure 16 kgC- body carbon steel

- Q: Why is copper used in cryogenic valves?

- The rigidity of copper is better, and the friction parts are not easy to produce adhesion. The influence of temperature on copper is smaller than that of steel. Especially in the valve stem, there is also the important gear part, copper!

- Q: Is there any problem with connecting the geothermal valves with other geothermal pipes?

- Can be universal,Material is the same, the fuse will not cause shrinkage when you can use

- Q: What is the valve?

- Is the switch, switch on the pipeline and can walk on water, air, oil and so on go. A lot of categories, you can control the on-off, control pressure safety valve, as well as a lot of filtering valves.

- Q: What does the valve specification "3/4CL150" mean?

- Size: DN20 pressure rating: 150 pounds American Standard

- Q: Is the filter also valve?

- Classification, filter does not belong to the valve filter is indispensable to a device on the pipe conveying medium, usually installed in the valve, pressure relief valve, inlet water valves or other equipment end, used to remove impurities in the medium, to protect the normal use of valves and equipment. When the fluid enters the filter cartridge has a certain size, the impurities are blocked, and clean filtrate from the filter outlet, when cleaning, as long as the removable cartridge is removed, you can reload after treatment, therefore, maintenance is extremely easy to use.

- Q: What valve is the YQZ45X-16Q?

- Specifically, YQ usually is the enterprise code, Z valve, 4 representative flange, 5 representatives of the dark bar, X (soft) rubber seal (gate coated with rubber material), nominal pressure 16 representative (PN) 1.6Mpa, Q on behalf of the valve body is made of ductile cast iron. If you add the valve bore (DN), it will be more detailed.

- Q: How can the material be checked by valve approach? What experiments do you need?

- May refer to the valve pressure test principle and the pressure test matters needing attention.(1) in general, the valve shall not be subject to strength test, but the body and bonnet shall be subjected to strength tests after the repair of the valve body and bonnet or corrosion damage. For the relief valve, the constant pressure and seat return pressure and other tests shall be in accordance with the specifications and the relevant regulations.(2) the installation of the valve should be done for strength and tightness test. Low pressure valve sampling 20%, if not qualified should be 100% of the inspection; medium and high pressure valve should be 100% of the inspection.(3) the installation position of the valve shall be in the direction of easy inspection during the test.(4) welding connection valve, not with blind plate pressure test can be used when the cone seal or O ring seal pressure test.(5) when hydraulic test, the valve air will be excluded as much as possible.(6) the pressure should be increased gradually during the test, and the pressure will not be sudden and sudden.(7) strength test and sealed test duration is generally 2~3min, important and special valves should last 5min. Small caliber valve test time can be a little shorter, large caliber valve test time can be longer. During the test, the test time can be extended if in doubt. Strength test, does not allow the body and bonnet sweating or leakage. Sealing test, the general rotor valve only once, the safety valve, high pressure valve and other raw valve to be carried out two times. When testing for the low pressure, large diameter valve is not important and there are provisions to allow leakage of the valve, allowing a small amount of leakage; the common valve, power station valve, marine valves and other valve requirements vary on leakage requirements according to relevant regulations.

Send your message to us

Butterfly Valve with Good Quality with Plastic Handle

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords