PPR Eblow Watering Irrigation used in Industrial Fields

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

Nowadays PPR pipes win more attention and have been used all over the whole world more widely with its excellent sanitization performance, high heat resistance, compression resistance, corrosion resistance, pliability and seismic performance which make PP-R the real environmental friendly pipe

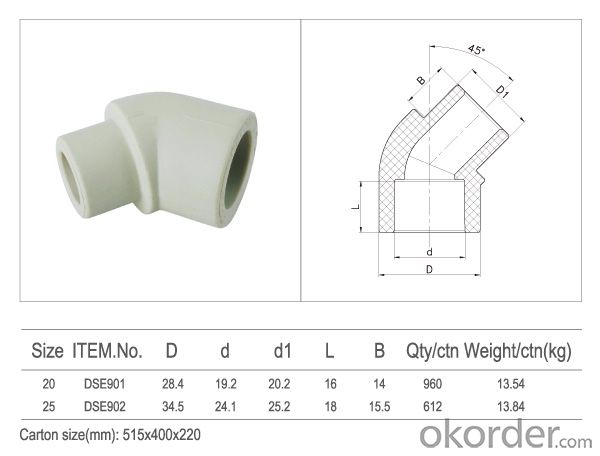

Specification

1. Light weight, easy and quick assembly

2. Most suitable for carrying drinking water

3. Excellent corrosion and chemical resistance

4. Bacteriologically neutral

5. Low thermal conductivity

6. Safe and watertight joints

7. Reduce heat loss

8. Resistance to scaling

9. Resistance to frost

10. Usable in seismic areas

11. Resistance to abrasion

12. Resistance to stray current

13. Eco-friendly

14. Long operational durability

Product Description

Product Show

Our Services

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.

- Q:Can plastic pipe fittings be used for water supply in remote areas?

- Yes, plastic pipe fittings can be used for water supply in remote areas. Plastic pipes and fittings are lightweight, durable, and resistant to corrosion, making them suitable for long-distance transportation and installation in challenging terrains. Additionally, plastic pipes are cost-effective and easy to handle, making them a practical choice for remote areas with limited resources and infrastructure.

- Q:How do you connect plastic pipe fittings to PVC pipes?

- To connect plastic pipe fittings to PVC pipes, you can use PVC cement or adhesive specifically designed for joining PVC materials. Simply apply the cement to the inside of the fitting and the outside of the PVC pipe, then push them together firmly. Allow sufficient time for the cement to dry and create a strong, permanent bond between the plastic pipe fittings and PVC pipes.

- Q:Are plastic pipe fittings resistant to waterborne bacteria?

- Yes, plastic pipe fittings are generally resistant to waterborne bacteria. They are non-reactive to water and do not provide a favorable environment for bacterial growth, making them an effective choice for preventing contamination in water systems. However, it is important to note that proper installation, maintenance, and regular cleaning are essential to ensure optimal resistance against waterborne bacteria.

- Q:Are plastic pipe fittings resistant to chemical corrosion?

- Yes, plastic pipe fittings are generally resistant to chemical corrosion.

- Q:Are plastic pipe fittings resistant to gasoline and oil?

- Yes, plastic pipe fittings are generally resistant to gasoline and oil.

- Q:Do plastic pipe fittings require regular maintenance?

- Plastic pipe fittings generally do not require regular maintenance. However, it is important to periodically inspect them for signs of wear, leaks, or damage. Regular maintenance might include checking for loose connections, replacing damaged fittings, and ensuring proper alignment.

- Q:How do you connect plastic pipe fittings together?

- Plastic pipe fittings can be connected together using a variety of methods such as solvent cementing, compression fittings, push-to-connect fittings, or heat fusion techniques. The specific method used depends on the type of plastic and the fitting type, but generally involves cleaning and preparing the surfaces, applying adhesive or inserting the pipe into the fitting, and allowing sufficient time for the connection to set or cool before applying pressure.

- Q:Can plastic pipe fittings be used in HVAC systems?

- Yes, plastic pipe fittings can be used in HVAC systems. Many modern HVAC systems utilize plastic pipes and fittings due to their durability, corrosion resistance, and ease of installation. Plastic fittings can be used for various applications such as connecting pipes, diverting airflow, and controlling the flow of fluids or gases within the HVAC system. However, it is important to ensure that the specific plastic material and fitting type chosen are compatible with the intended HVAC system requirements and operating conditions.

- Q:How do plastic pipe fittings compare to ABS fittings?

- Plastic pipe fittings and ABS fittings are both commonly used in plumbing systems. However, there are some key differences between the two. ABS fittings are made from a stronger and more durable material, making them resistant to impacts and chemicals. On the other hand, plastic pipe fittings are typically cheaper and easier to install. Ultimately, the choice between the two depends on the specific application and requirements of the plumbing system.

- Q:Can plastic pipe fittings be used for portable water systems?

- Yes, plastic pipe fittings can be used for portable water systems. However, it is essential to ensure that the fittings are made from materials approved for potable water use, such as those meeting NSF/ANSI 61 standards. Additionally, proper installation and regular maintenance are crucial to prevent any potential contamination risks and maintain the safety of the portable water system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR Eblow Watering Irrigation used in Industrial Fields

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords