Brown Craft Paper Laminated with Plastic Film Used for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Brown Craft Paper Laminated with Plastic Film Used for Packing:

Brown Craft Paper Laminated with Plastic Film Used for Packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Brown Craft Paper Laminated with Plastic Film Used for Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Brown Craft Paper Laminated with Plastic Film Used for Packing:

Excellent quality control

Experienced factory produced

SGS passed

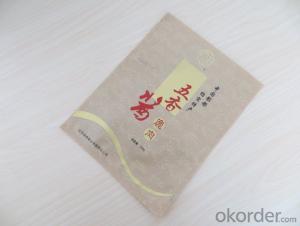

3. Brown Craft Paper Laminated with Plastic Film Used for Packing Photos:

4. Brown Craft Paper Laminated with Plastic Film Used for Packing Specification:

1. Material: PE, LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Brown Craft Paper Laminated with Plastic Film Used for Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How to evaluate the quality of a food packaging bag design? From what angle?

- Most importantly, the design of this package has a direct sensory connection to this product. Let's take a simple example, moon cake, which is a more common packing, is packed in a plastic bag and can only buy a few dollars, but it will appreciate a lot more when it is put into the gift box. It's in the bag. Moon cake is just food. In the gift box, it becomes a gift. Before consumers buy, the product is analyzed as a food or a gift, which is the most important message that the mooncake package conveys to the consumer.

- Q: Why a lot of the packaging bag surface is silver foil?

- Because candies are also considering moisture side so many sweets are wrapped in wax paper (because the wax paper can prevent water entering)For example, chocolate is a special kind of candy, its melting point is 36 degrees, it is very easy to get the temperature melting in the hand, so the reason is tin tin foil, the hands of the temperature can be very good to pass out to prevent the chocolate melts quickly.

- Q: How much is the 1 wire in the food packing bag printing industry?

- 1 wire =0.01 mm, refers to the thickness of the bag units!Custom food packaging bags, I recommend to have experience in custom food packaging bag manufacturers, because it can reduce the cost and time for many of you, can give you a lot of packaging design and customized recommendations.

- Q: The difference between a vacuum and a vacuum in a food package

- So, the difference is very clear, is the vacuum packaging bag of the air as much as possible out, but the inflation is the air in the bag is replaced by nitrogen or carbon dioxide and other inert gases, the purpose is as far as possible to reduce food and air contact oxidation process, slow food, avoid food rapid deterioration.

- Q: What are the soft and hard sides of plastic bags? Material or process technology?

- On the basic price will be a little higher, the brittle is generally PP or PET is done, some relatively low grade. Soft is generally made of multi-layer coextrusion film, barrier, and feel good. This soft about 27000 yuan / ton, while the PP film generally as long as 17000 yuan / ton, ten thousand tons a difference.

- Q: What material is the surface of the packing bag such as instant noodles, pickled mustard tuber, small bread and so on? Why should we add this layer?

- First, it is easy to heat seal, otherwise only aluminum foil can not be sealed;Two, high barrier plastic film preservation effect is also very good, can increase its number of layers, reduce aluminum foil thickness, thereby reducing costs

- Q: Dried fish vacuum packaging packing bag can not puncture

- Anti piercing vacuum packaging bags, first of all, choose the material of the bag to have toughness, followed by the thickness of the bag

- Q: Antistatic packaging bag with chip

- Then anti-static shielding bag, black is conductive electrostatic material, regular 1000 ohm resistance, or is translucent gray, middle layer aluminized bag, play an important role in shielding

- Q: What kind of packaging bag does polysilicon use?

- Disposable material into a double-layer polyethylene bag, and then packing bags into the packing box or packaging barrel. Block polysilicon packaging specifications are net 5000g or 10000g per bag.

- Q: What's bread packing? Polyethylene film, waterproof cellophane, etc.

- Currently, about 90% of the bags are packed in polythene plastic bags.

Send your message to us

Brown Craft Paper Laminated with Plastic Film Used for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords