Scotch Heavy Duty Packaging Tape 8-Pack - BOPP Tape Tan Colour Resistance to Cold, Heat and Waterproof High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m

- Supply Capability:

- 2000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bopp Tape Water Based Acrylic Super Clear and Low Noice Thickness 50 Micron

Product Description

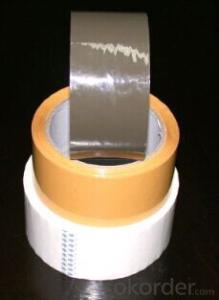

Bopp Tape is of Bopp film as the carrier, coating with water based acrylic adhesive. General purpose of Bopp Tape: widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

FEATURES:

l Excellent in adhesion and flame retardant

l Resistance to cold, heat and aging.

l High Temperature stability

l High mechanical strength and good impact resistance

l Ideal for use in dispensers

l Printable

Data Sheet

| Item NO. | BP-40 |

| Carrier | Bopp Film |

| Adhesive | Water Based Acrylic |

| Thickness (mm) | 40 |

| Intial Tack (14# mm) | ≥18# |

| Adhesion to Steel (N/25mm) | 5 |

| Holding Power (H) | ≥24h |

| Elogation (%) | ≤180 |

| Packing | Carton |

| Delivery | With 10-20 days after deposit |

| Payment | TT & LC |

Authorized Certificate

Production Line

Exhibition Domestic and Oversea

Company

China National Building Materials Group is a state-owned company. As World Top 500 companies, we have clients from over 160 countries and wholly-owned overseas subsidiaries and branches in 10 countries. We supply adhesive tape for over twenty years.

We supply various adhesive tapes: cloth tape, double sided tape, PVC tape, aluminum foil tape, Opp tape, masking tape and so on. All our products have been SGS and ISO9001 certified and exported with Grade AA approval. The quality and performance all meet the advanced international levels.

We not only own professional manufacturers in China, but also work with many famous brands as agents. We can provide OEM Design & Brand as you required.

FAQ

1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

2. What can we do for you?

Professional consultation on your local market

Custom-made advices for your need

Free samples

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Satisfactory sales service

3. Delivery time

7-25 days after receiving the deposit

4. Packing and Shipping

36 Rolls per Caron.

5. What is other specifications of bopp tape?

Type: Low noice Bopp packing tape.

Supper clear Bopp packing tape

- Q: Is packaging tape flammable?

- Yes, packaging tape is typically made from materials such as polypropylene or polyester, which are not highly flammable. However, it is important to note that some packaging tapes may have adhesive properties that contain flammable components. It is always best to refer to the specific packaging tape's safety data sheet or consult the manufacturer for accurate information regarding flammability.

- Q: What's the name of the sealing tape specification 40*50y y?

- Yard English words, yards. One yard equals 1 yards =0.9144 meters

- Q: Is packaging tape resistant to extreme temperatures or weather conditions?

- Packaging tape is typically constructed to endure extreme temperatures and diverse weather conditions, although the degree of resistance may fluctuate depending on the tape's specific type and quality. Most packaging tapes are composed of robust materials like polypropylene or PVC, renowned for their durability and ability to withstand environmental elements. These tapes are often treated with specialized adhesives that retain their stickiness even in harsh temperatures or humid surroundings. Concerning extreme temperatures, packaging tapes are generally engineered to withstand a broad spectrum, including both frigid and scorching extremes. They can typically endure temperatures as low as -20 degrees Celsius or as high as 60 degrees Celsius without compromising their adhesive properties or becoming brittle. Similarly, packaging tapes are designed to exhibit resistance against diverse weather conditions. They are formulated to repel moisture, humidity, and UV radiation, which are prevalent factors that can deteriorate tape quality. This resistance ensures that the tape remains intact and efficient, even when exposed to rain, snow, or direct sunlight. It is crucial to note that although packaging tape is generally resistant to extreme temperatures and weather conditions, prolonged exposure to such circumstances can still impact its durability. Therefore, it is advisable to store and utilize packaging tape in a controlled environment whenever feasible to guarantee maximum effectiveness.

- Q: Can packaging tape be used on all types of surfaces?

- When it comes to packaging tape, it generally works well on a wide variety of surfaces. However, it is crucial to take into account the specific characteristics of the surface. Packaging tape is specifically designed to stick to different materials like cardboard, paper, plastic, and even certain metals. Its common uses include sealing boxes and securing packages. Nevertheless, there are surfaces that may not be suitable for packaging tape, particularly those that are extremely smooth, oily, or coated with a non-stick substance. In such instances, the tape might not stick properly or could easily peel off. It is always recommended to test the tape on a small and inconspicuous part of the surface before applying it extensively. Furthermore, there are various types of packaging tapes available, each with its own unique adhesive properties. Therefore, it is crucial to select the appropriate tape for the intended surface in order to ensure proper adhesion and durability.

- Q: Can packaging tape be used for other purposes besides packaging?

- Yes, packaging tape can definitely be used for other purposes besides packaging. Due to its strong adhesive properties and durability, it can be used for a variety of tasks. For example, it can be used for household repairs such as fixing a broken book spine or securing loose cables. Additionally, it can be used for crafting projects like creating temporary or permanent decorations, making durable envelopes, or even in DIY projects like creating makeshift labels or organizing items. Furthermore, packaging tape can also be used for temporary fixes, such as sealing small leaks or cracks in pipes or containers until a permanent solution is found. The versatility of packaging tape makes it a handy tool to have around the house or office for various purposes beyond just packaging.

- Q: Is packaging tape resistant to chemicals or solvents?

- Yes, packaging tape is generally resistant to chemicals or solvents. Most packaging tapes are made from materials such as polypropylene or polyvinyl chloride (PVC) which have good chemical resistance properties. These materials are designed to withstand exposure to a wide range of chemicals and solvents commonly encountered in industrial or commercial environments. However, it is important to note that the specific resistance of packaging tape can vary depending on the brand, type, and quality of the tape. Therefore, it is always recommended to check the product specifications or consult the manufacturer for detailed information on the chemical resistance of a specific tape.

- Q: Can packaging tape be used for sealing wooden crates?

- Yes, packaging tape can be used for sealing wooden crates. It provides a strong and secure bond, ensuring that the crate remains sealed during transportation or storage. Packaging tape is designed to adhere to various surfaces, including wood, making it an effective choice for sealing wooden crates. However, it is important to consider the weight and size of the crate before solely relying on packaging tape. For heavier or larger crates, it may be necessary to reinforce the seal with additional methods such as nails or screws.

- Q: How does packaging tape perform on rough or uneven surfaces?

- Packaging tape generally performs well on rough or uneven surfaces. Its adhesive properties allow it to adhere securely to most surfaces, including those that are not perfectly smooth. The tape is designed to conform to the contours of the surface, ensuring a tight seal and preventing any potential lifting or peeling. However, it is important to note that the effectiveness of packaging tape on rough or uneven surfaces may vary depending on the specific type and quality of the tape being used. Some tapes may have stronger adhesion or more flexible backing materials, which can further enhance their performance on rough or uneven surfaces. In certain cases, it may be necessary to apply additional pressure or use multiple layers of tape to ensure a secure bond. Additionally, it is worth considering alternative packaging materials, such as stretch film or strapping, for particularly rough or irregular surfaces, as they may provide a more reliable solution.

- Q: Can packaging tape be used for sealing envelopes?

- Yes, packaging tape can be used for sealing envelopes. It provides a strong and secure seal that helps protect the contents of the envelope.

- Q: Can packaging tape be used for sealing packages with sharp or pointed objects?

- Indeed, packaging tape is capable of sealing packages that contain sharp or pointed items. Its purpose is to create a reliable seal for packages, effectively keeping together those that hold sharp or pointed objects. Nonetheless, it is crucial to ensure that the tape is tightly fastened and covers all edges and corners of the package to avoid any potential harm or damage during handling or transportation. Moreover, it is advisable to apply multiple layers of tape or employ supplementary protective measures, like cushioning materials, to reinforce the security and safeguard the sharp or pointed items enclosed within the package.

Send your message to us

Scotch Heavy Duty Packaging Tape 8-Pack - BOPP Tape Tan Colour Resistance to Cold, Heat and Waterproof High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m

- Supply Capability:

- 2000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords