Black Film Faced Plywood Marine Plywood Poplar Core 4*8ft 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

SIZE:1220X2440;1250X2500 , ETC.

2.BLACK/BROWN/RED FILM

3.CORE:POPLAR/COMBI/HARDWOOD

4.GLUE:MR/MELAMINE/WBP/REAL PHENOLIC

Goods Description

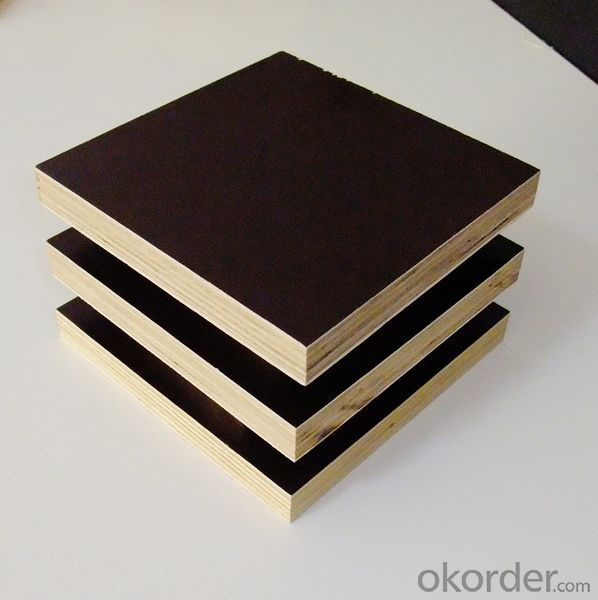

Plywood size: | 1220*2440mm , 1830*915mm,4*8 ft,3*6ft | |||

Glue | Melamine glue/MR WBP | |||

Core | pine,hardwood,eucalyptus,combi etc | |||

F/B | Black film, brown film, anti-slip film | |||

Application | High-rise construction, building construction, forming concrete, can be widely used for building concrete. | |||

Thickness range | 12mm~20mm | |||

Thickness tolerance: | +/-0.5mm | |||

Standard quality | natural wood face, one time hot pressing | |||

High quality | double side film faced,twice hot pressing and sanding | |||

thickness: | gross weight ( kg/pcs) | 20ft container(pcs) | 40ft container(pcs) | Using times |

13mm | 25.16 | 690 | 870 | 6~15times |

14mm | 27.12 | 640 | 810 | 6~15times |

15mm | 29.05 | 600 | 750 | 6~15times |

Product Features

1. Light Weight: We choose the high grade eucalyptus and poplar as the basic material, they

are very light, so our faced plywood is convenient for transporting, and only one per-

son could delivery single formwork by hand.

2. Easy To Cut: according to the construction, the formwork could be cut into the required size.

3. Re-used: film faced plywood could be used 8-12 times.

4.Multi Using: film faced plywood could be used for wall, slab, column, beam and bri-

dge concrete pouring etc..

FAQ

1.free samples are available

2.MOQ is one 40HQ container

3.delivery time 30 days after getting deposit

4.payment term T/T or L/C at sight

- Q: Class I resistant weather plywood Class II water resistant plywood

- Medium density fiberboard: density fiberboard is a kind of man-made sheet, it is the plant fiber as raw material, the chipping, fiber separation

- Q: Selection of plywood in plywood production

- Artificial veneer is the use of relatively low prices of logs cut into veneer, made by a certain process pressure made of wood, and then cut into a beautiful pattern decorated veneer.

- Q: How do you choose plywood in plywood production?

- Another problem is the growing number of furniture produced by the panel, although these furniture, "cypress" and other grain appearance,

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q: What is the best way to fix multi-layer plywood?

- The main tree species are: camphor, willow, poplar, eucalyptus and so on.

- Q: The Decorative veneer veneer plywood grade classification

- for example,such as some manufacturers logo level "AAA", which is corporate behavior.

- Q: Ordinary plywood is divided into four categories

- According to different density, divided into 80, 70, 60 three categories. Quality level for the premium, one, two three

- Q: What is the amount of construction works used for this plywood?

- Three types of plywood for moisture-resistant plywood, can be immersed in cold water for a short time, suitable for indoor use at room temperature. For furniture and general construction purposes;

- Q: Plywood in the processing of defects

- Separation delamination The separation of two adjacent veneers due to lack of glue or poor glue.

- Q: What are the shortcomings of plywood

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides

Send your message to us

Black Film Faced Plywood Marine Plywood Poplar Core 4*8ft 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords