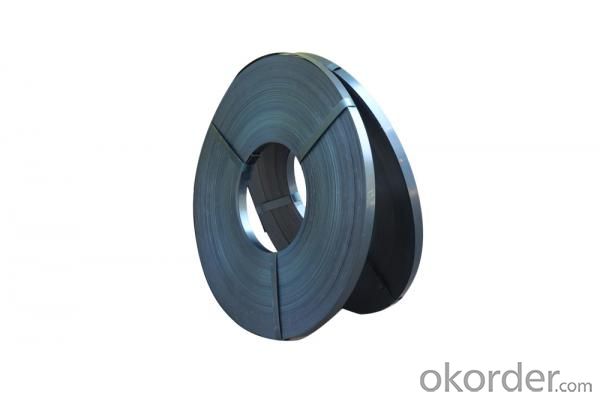

black/blue/galvanized steel packing strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

[Sort of steel packing strips]:

(1) White steel packing strips

(2) Blue steel packing strips

(3) Paintbaked steel packing strips(black,green,gray,yellow etc.)

[Mechanical properties]:

(1)Ordinary steel strips():

tensile strengthσb≥58-78Kg/mm2(580-780Mpa),elongation3%-5%.

(2)Ordinary steel strips():

tensile strengthσb≥78-90Kg/mm2(780-900Mpa),elongation3%-5%.

(3)High quality steel strips:

high high intesity,good capability,bearing impact.tensile strength: 90-100Kg/mm2 (900-1000Mpa) , elongation5%-10%.

[Specification]:

BWG28×3/8'' , 1/2'' ,5/8'' ( 0.36mm×9.5mm ,12.7mm ,16mm)

BWG27×3/8'' , 1/2'' ,5/8'' (0.40mm×9.5mm , 12.7mm ,16mm)

BWG26×1/2'' , 5/8'' , 3/4'' (0.45mm×12.7mm , 16mm , 19mm)

BWG25×1/2'' , 5/8'' , 3/4'' (0.50mm×12.7mm , 16mm , 19mm)

BWG24×1/2'' , 5/8'' , 3/4'' (0.55mm×12.7mm , 16mm , 19mm)

BWG23×1/2'' , 5/8'' , 3/4'' (0.60mm×12.7mm , 16mm , 19mm)

BWG22×3/4'' , 1'' , 5/4'' ( 0.70mm×19mm , 25.4mm, 32mm)

BWG21×3/4'' , 1'' , 5/4'' (0.80mm×19mm , 25.4mm, 32mm)

BWG20×3/4'' , 1'' ,5/4 '' , (0.90mm×19mm , 25.4mm , 32mm)

BWG19×3/4'' , 1'' , 5/4'' (1.0mm×19mm , 25.4mm, 32mm)

[Others]:

We can produce special specification as per customers request,and we can make the edge smoother of the steel packing strips.

Specifications

steel packing stripBlack or galvanized

Material:Q195 or Q235

Package:50kgs/coil,or as customer request

The steel packing strip has the following advantage:

Surface treatment | Black painted wax,Blue or Galvanized surface |

Size | thickness:0.3mm-1.0 mm,width:12.7-32mm or any width as your request.

|

Package | Ribbon & Oscillated,50kgs/coil,or as customers requirements

|

- Q: What is the difference between iron and wrought iron

- Generally less than 0.2% carbon content that wrought iron or iron, the content of 0.2-1.7% in the steel, content of more than 2% is iron. Iron soft, good plasticity, easy deformation, strength and hardness were lower, not widely used; iron carbon, hard and brittle, almost no plastic.

- Q: The difference between iron and wrought ironDon't say one is raw, the other is ripe

- Because the graphite is soft, with lubrication, so the cast iron has good abrasion resistance, cutting and casting performance. But it is not anti digital strength, it is not only used for producing all kinds of forging, casting, such as a variety of machine tool bed casting base, iron pipe. Ductile iron to carbon exists in spherical graphite morphology the mechanical properties of gray iron, far and close to steel, it has excellent casting, machining and wear resistance, has a certain flexibility, widely used in the manufacture of gear, crankshaft, piston and a variety of advanced casting machine parts. In addition to silicon, manganese, nickel or other elements of a particularly high amount of iron, alloy such as iron, ferrosilicon, ferromanganese, commonly used as raw material for steelmaking. In certain alloy steel-making pig iron, steel can improve performance.

- Q: Is the cast iron pot / pig iron pot good?

- From the material, the pot is divided into fine iron pot and cast iron pot two categories. Iron is made of gray iron casting made by melting model, slow heat transfer, uniform heat transfer, but the pot ring thick, rough texture, easy to crack; fine iron is made of black metal forging or hand hammer, the pan ring thin, fast heat transfer, the characteristics of beautiful appearance. It is understood that the iron pot has a characteristic, when the fire temperature exceeds 200 degrees, iron will send out through certain heat transfer to the food to control the temperature of 230 DEG C, and fine iron is directly to the temperature of fire to food. For the average family, use a cast iron pan. But the iron pot also has advantages, first, because it is a fine iron casting, less impurities, therefore, heat transfer is even, not prone to sticky phenomenon. Second, because the material is good, the pot can be made very thin, the pot temperature can be higher. Third, high grade, smooth surface, clean work, good to do.

- Q: What is cast iron? What is the difference between cast iron and ordinary iron?

- Pig iron and cast iron are two distinct and closely related concepts.Pig iron is a carbon iron containing carbon 2.11%-6.67% and contains many non iron impurities. The impurity elements of pig iron are mainly silicon, sulfur, manganese, phosphorus and so on. Raw iron is hard and brittle, lacks toughness, has almost no plastic deformation ability, so it can not be machined by forging, rolling and drawing. But with high silicon cast iron (gray iron casting) and good cutting performance.

- Q: The difference of ductile iron and gray iron manhole cover of manhole cover

- From the smelting method, ductile iron is in the smelting of iron in adding inoculant and spheroidizing agent that graphite by dispersing flocculent into spherical ferrite to reduce the fragmentation, increase strength, performance mentioned to arrive.5, is the gray iron manhole cover does not add any auxiliary materials, pig iron smelting directly into molten iron, then poured into the manhole cover. But ductile iron manhole cover is to add spherical agents, rare earth, magnesium and other metal alloys, so now the market and the relevant departments requested the use of ductile iron manhole cover. That is because ductile iron covers, in the bearing capacity is far beyond the gray iron manhole cover.

- Q: Why is cast iron used for motor end caps? Is regular iron OK?

- First of all, you should correct your statement. What you call ordinary iron should refer to the steel plate, because the material definition of "iron" refers to pure iron, which is rare. The end cover of the motor is cast iron because the shape of the end cover is more complicated. It is easier to process with cast iron. It is very troublesome to use steel plate. Followed by the cast iron has been fully able to meet the requirements of the motor to the end cap, and cast iron is not easy to deformation.

- Q: Pig iron electrode welding high speed steel is good?

- If it is high speed steel, welded by alloy steel electrode WE600 recommendations, is a low heat output, suitable for special nickel chromium alloy steel electrode welded all-round, universal design is extremely wide, the general strength of parent materials with high strength, excellent welding performance, stable arc, beautiful shape of seam, in oil, under the condition of water and rust can welding effect is excellent, can different welding steel.

- Q: How can the toilet iron pipe rupture be repaired?

- Go to the big plumbing shop and tell him what your pipe is, what the material is, how big it is, and what part of it leaks. Buy him a rush repair section (two kinds of straight tubes and big bags). Go back and screw your own;

- Q: What's the color of the pig iron?

- Iron carbon content is greater than 2% (2.11%) of the iron carbon alloy industry, iron carbon content is generally 2.5%--4%, Si, Mn, S and P, and other elements, is the use of iron ores in blast furnace products.

- Q: Pure iron, pig iron reacts with dilute acid that fast? Why?

- Pig iron is quick. Carbon, iron, dilute sulfuric acid in a pig iron form a battery

Send your message to us

black/blue/galvanized steel packing strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords