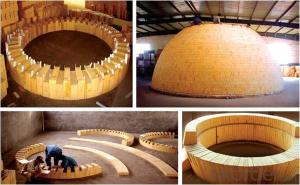

Silica Brick for Coke Oven - Best Seller

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

silica bricks for coke oven passed ISO certified

1.good resistance to acid slag and good heat conductivity

2.RUL 1620

best-selling silica bricks for coke oven passed ISO certified .it is made of quartz stone material,the content od Sio2 is above 93%,it has good resistance to acid glad and good heat conductivity,and the refractoriness is 1690-1710.C,RUL is beyond 1620.C

items | Furance bottom/ furancre wall | rests | allow deviation |

SiO2 % | ≥94.5 | - | |

Al2O3 % | ≤1.2 | - | |

Fe2O3 % | ≤1.2 | - | |

CaO % | ≤2.5 | - | |

0.2MPa RUL (°C) | 1650 | -10 | |

True density (g/cm3) | ≤2.33 | ≤2.34 | +0.01 |

Residual quarlz% | ≤1.0 | - | |

AP% | ≤22 | ≤24 | +1 |

CCS(MPa) | ≥40 | ≥35 | 10% |

PLC(1450°C *2h) % | 0~0.2 | - | |

Thermal expansion(1000°C) % | ≤1.28 | ≤1.30 | +0.03 |

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Different insulation methods can be adopted according to the length of the stop time and the location and equipment of the overhaul. Gold, refractory material factory specializing in the production of various specifications of brick

- Q: Common bond brick?

- Lime should contain a lot of active CaO, I decompose CaCO3 and MgCO3 not more than 5%, Al2O3+Fe2O3+SiO2 no more than 5%. When the content of large particles, burned Ca-CO3 and over burned lime, the product produced caves, affecting the quality of products.

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- The main damage of silicon carbide side wall brick is stress damage, not chemical erosion. Chemical damage is formed prior to the formation of the groove, and the damage to the chemical erosion is little after the formation of the groove.

- Q: Semisilica brick interpretation

- High temperature volume stability. Volume change is small.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- This is a kind of refractory material is divided into three types: semisilica brick (A12O315 ~ 30%), clay brick (A12O330 ~ 48%), high aluminum brick (A12O3>48%).

- Q: The brick is mainly used in the place?

- Open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts.

- Q: What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon, aluminum, clay and so on:

- Q: The chemical composition of silica brick and its physicochemical index?

- Brick refers to the refractory products in more than 93% of the content of SiO2

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

Send your message to us

Silica Brick for Coke Oven - Best Seller

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords