Best Selling Products in Europe Vinyl PVC Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

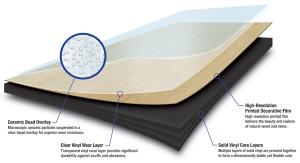

W/L: 0.5mm

Surface: Crystal Texture

Vinyl Plank

UV matt

Size: 1227*157*3.0mm

Why Choose Us

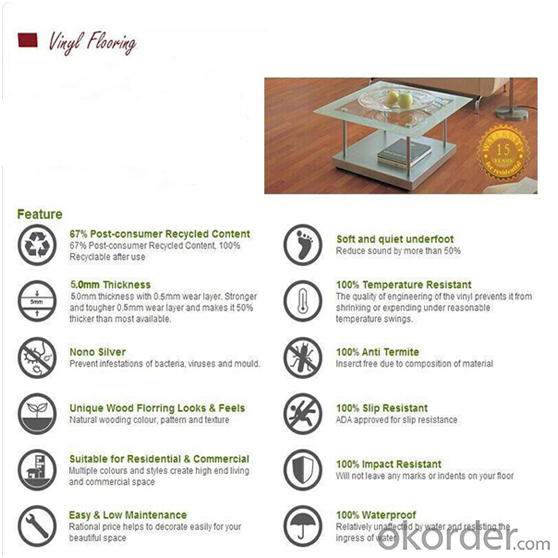

1. 15-Year professional experience in CNBM Flooring.

2. The Fastest Delivery Speed

3. Excellent After-sales Service

Technical Data

Safety Criteria | Standard | Value |

Flammability | EN 13501-1 | Bf1 |

Slip resistance | EN13893 | DS |

Formldehyde Emission | EN717-1 | None |

Color Fastness | ISO 105-BO2 | ≥ 6 |

Castor Wheel Test | EN425 | Pass |

How to install:

Vinyl tiles have always easy to install.but today's no-glue vinyl tile system are even easier.the tiles lock together at the edges to form the surface of the floor,with nothing attaching them to the subfloor, so you can lay them over any solid,flat aurface. Vinyl lock tiles,are formed to look like wood,with a patented locking system.

Instrctions:

1.Remove the floor trim fromt he perimeter of the floor with your hammer and prybar. Don't break it. Set it aside.

2. Lay the first row of this vinyl tiles alongside your starting wall, locking them together at the ends. Put shims between the tiles and the wall, to create a space that will allow for floor expansion. Lay all the full tiles that will fit.

3. Measure the space at the end of the first row of tiles. Use your utility knife to cut a tile to size, running the knife alongside a straight-edge to score it, and then snapping the tile. Lay it with the cut side facing the wall.

4. Lay the next courses of tiles alongside the first building out in courses. Start each course at the opposite end of the room as the previous course, so the ends of the tiles don't line up between courses. Lock the tiles together by their long edges,pushing them in at a downward angle, locking then, then dropping then into space. Cut the ends as necessary.

5. Cover the whole floor. Cut the final course of tiles length-wise, so they fit against the wall with a small gap there(about 1/4 inch).

6. Nail the floor trim back in place, using your hammer and finish nails, to seal off the spaces by the walls. Nail toe trim into the walls and not through the flooring.

- Q: Can the bathroom PVC plastic floor?

- 1, can shop. But do not use ordinary plastic floor, recommended with coil, and the surface should have a concave and convex non slip texture, glue to use two components of waterproof glue line, the construction of more stringent.

- Q: Floor mounted mats are not ordinary plastic films?

- But in the damp ground or geothermal conditions in tidal and geothermal temperature (especially geothermal temperature exceed the standard) under the action of the tape is extremely easy to cause the joint degumming, breathable, causing the floor bulge, Alice, sound or color etc.

- Q: Board PVC plastic floor plastic toxic

- PVC floor "refers to the use of polyvinyl chloride material production floor. Specifically to the polyvinyl chloride and its copolymerization resin as the main raw material, filler, plasticizer, stabilizer, coloring agent and other accessories, in the continuous sheet substrate, the coating process or by rolling or extrusion process and.

- Q: PVC plastic floor defects

- PVC, also known as polyvinyl chlorideAdvantages: corrosion resistance! Good tensile strength; compressive strength!Disadvantages: poor ventilation; flexible than other plastics; quality is not good PVC also has a small amount of toxicity; at low temperature is more brittle; smell is relatively large!Uses: agricultural water supply and drainage, irrigation, rainwater pipes, exhaust pipes, wire conduits, industrial anti-corrosion pipe, toys, stationery, plastic flooring, etc..

- Q: The home is all ceramic tile or plastic floor

- It is not necessary, the general plastic floor for the warehouse floor, fire and less dust

- Q: Ask how to install plastic floor

- Tools: a knife blade, remove the plastic floor flat at room temperature for at least 24 hours, two on each side of the wall to find the center point, draw the cross center line on the floor, the ground is divided into four areas, and then from the central to the laying of three four, clean the ground, make sure the ground can begin after the laying of four, clean (without gum floor) with a scraper coated plastic tile special adhesive, five (Beijiao floor) tore the floor backing off the paper, starting from the six floor of the center line laying in all directions, each piece of tile must be close to the junction, glued to the ground, to avoid the gap seven, laying to the wall the floor tile cutting required size

- Q: Classroom platform shop plastic floor with no need to do self leveling?

- For example: the stadium used (table tennis, gym, badminton, basketball), shopping malls, dance, stage, KTV, hotel, hospital, hotel, operation room, family, kindergarten, School

- Q: Worried about a long time, plastic aging, small ironExpose the floor.

- General furniture set foot nails, there is no problem.Because, in general, the furniture will not often move, feet nail support role, and the plastic nails are relatively thick, no problem

- Q: What are the hazards of plastic floor?

- Plastic floor leather, although difficult to burn, self extinguishing, but at high temperatures, will decompose harmful gases, excessive inhalation, suffocating. Floor leather containing lead compounds, in the use of the process, with the floor leather wear, lead content continues to spread, the formation of lead dust in the air, easy access to infants and young children.

- Q: What are the main construction process of laying plastic floor

- (2) soft plastic floor plate:Primary treatment, elastic line, plastic floor wax, degreasing, pre laying groove blanking, scraping, paste, welding, rolling, maintenance.

Send your message to us

Best Selling Products in Europe Vinyl PVC Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords