Best Quality Cold Roll Zinc Glvanizing Steel Coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 23 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

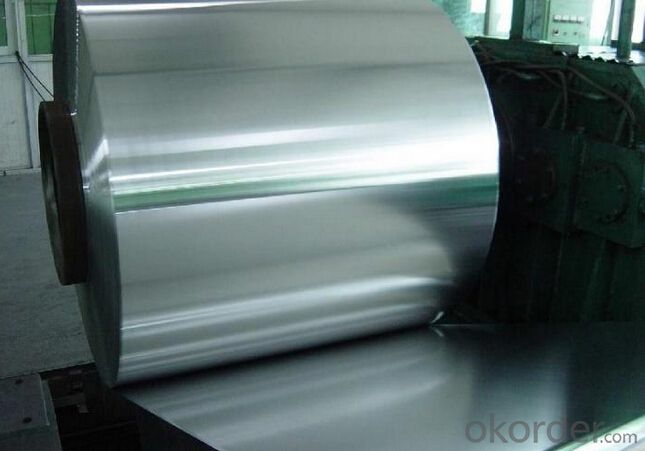

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Commodity | Hot dip galvanized steel coil and sheet |

| Techinical Standard: | JIS 3302 / ASTM A653 / EN10143 |

| Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

| Types: | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.14-3.0mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating: | galvanized |

| Zinc coating | Z30-275g/m2 |

| Surface treament | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

| Surface structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

| ID coil | 508mm or 610mm |

| Coil weight | 3-8 MT per coil |

| Package: | Properly packed for ocean freight exportation in 20''containers |

| Application: | Industrial panels, roofing and siding for painting |

| Price terms | FOB,CFR,CIF |

| Payment terms | 30%TT in advance+70% TT or irrevocable 70%L/C at sight |

| delivery time | 15-20 days after recepit of 30% TT |

| Remarks | Insurance is all risks |

| MTC will be handed on with shipping documents | |

| We accept the third party certificatation test |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of engine components?

- Steel coils are used in the manufacturing of engine components as they provide a strong and durable material for various parts. These coils are typically processed and shaped into specific components such as pistons, crankshafts, cylinder heads, and connecting rods, which are vital for the proper functioning of an engine. The high strength and heat resistance of steel make it an ideal choice for these critical components, ensuring the engine's reliability and performance.

- Q: What are the different types of steel coil finishes used in architectural applications?

- There are several different types of steel coil finishes that are commonly used in architectural applications. These finishes are applied to steel coils to enhance their appearance and provide additional protection against corrosion and weathering. Some of the most popular types of steel coil finishes used in architectural applications include: 1. Mill Finish: This is the most basic type of steel coil finish, where the coil is left untreated after being rolled. It has a dull, gray appearance and is often used in industrial and structural applications where aesthetics are not a primary concern. 2. Hot-Dip Galvanized: In this finish, the steel coil is immersed in a bath of molten zinc, which creates a thick layer of zinc coating on the surface. This finish provides excellent corrosion resistance and is commonly used in outdoor architectural applications such as roofing, gutters, and siding. 3. Galvalume: This finish is similar to hot-dip galvanized, but instead of pure zinc, it uses a combination of zinc and aluminum. Galvalume-coated steel coils offer superior corrosion resistance and are often used in high-end architectural applications, such as metal roofing and wall panels. 4. Pre-Painted: In this finish, a layer of paint is applied to the steel coil before it is shipped to the customer. This allows for a wide range of colors and finishes to be achieved, making it a popular choice for architectural applications where aesthetics are important. Pre-painted steel coils are commonly used in exterior cladding, garage doors, and decorative panels. 5. Stainless Steel: This finish is achieved by using a steel alloy that contains a high percentage of chromium. Stainless steel coils have excellent corrosion resistance and are often used in architectural applications where a clean, modern look is desired, such as handrails, elevator interiors, and kitchen appliances. Each type of steel coil finish offers unique advantages and is suitable for different architectural applications. The choice of finish depends on factors such as the desired appearance, level of corrosion resistance required, and the specific environmental conditions the steel will be exposed to.

- Q: What are the different grades of steel used in coil manufacturing?

- There are several grades of steel used in coil manufacturing, including but not limited to, low carbon steel (e.g., ASTM A36), high carbon steel (e.g., ASTM A684), stainless steel (e.g., AISI 304), and galvanized steel (e.g., ASTM A653). These grades are chosen based on the desired properties and requirements of the coil being manufactured.

- Q: I just got the game Red Steel for the Wii. I want to use the sword in multiplayer mode, but I can't find it. Is it only for single player?

- Dude i hate to break it to you but its only single player, and if your talking about the first Red Steel, you can only use the sword in special moments in the game or showdowns i think that's what its called, but i play Red Steel 2, and its a better game, and you can use the sword anytime you want to, but again no online play, but it would be kinda nice to have it, just a thought!!! LoL Hope that helps....

- Q: What are the different types of steel coil slitting techniques?

- There are several types of steel coil slitting techniques, including rotary slitting, loop slitting, and double slitting. Rotary slitting involves using circular blades to cut the coil into narrower strips. Loop slitting is a method where the coil is fed through a looped pit, and the blades cut the coil as it passes through. Double slitting is a technique where two sets of slitting knives are used simultaneously to cut the coil into multiple strips at once. These techniques are used in various industries to create narrower and more manageable steel strips for further processing.

- Q: i would like to make a dmascus steel knife, i have the cable but im not sure if its damascus steel or not, how do i tell? and if it isnt damascus steel how do i make a bar of it?

- Here's what you need, the cable should be a minimum of 9/16 with large wires. You need some borax (20 mule team from the store). A good hot coal, coke, or gas forge. If the cable has fiber rope in the center it will need to be removed. Fuse the ends of the cable to keep them from coming apart. I use my welder and while I'm at it I weld a handle to make it easier. Heat it in the forge when the forge is properly heated, rotate it. Some people will burn the oil out, but I've found that the forge does that just fine. Rotate the cable while it's heating. When it begins the turn red pull it out and sprinkle the borax over it, don't hold back use a lot. It will begin to melt and bubble into the steel. Put the cable back in the forge, rotate and watch. This is the critical part. When the steel starts to turn from orange/yellow to almost yellow/white take it out and lightly (I use a 2lb hammer) begin hammering the cable into a square or rectangle. If you do it right you'll notice that it will begin to fight the hammer, that's when you know the weld it taking place. You'll have to repeat the process down the length of the cable. Once you have the billet made you can begin the process of shaping the edge and tang. Once you have it shaped, follow proper forge procedure then grind all the yuck off and finish shaping. Then harden and temper and finish it out. Good luck. I almost forgot a very important part. Befor you start hammering put the cable in a vice while at welding temp (if you are strong you can use a couple of plyers) and twist it tight. On the next heat hold the cable in your left and and lay it on the anvil. Concentrate on your light hammer blows being on your side of the cable. This forces the cable strands together. If you are using smaller cable like 9/16 you can double the cable up and weld two peices together, it is easier and makes for a prettier blade. Doing this you don't have to worry about twisting the cable and you can hit it much harder to start with.

- Q: How are steel coils used in the production of steel framing systems?

- Steel coils are used in the production of steel framing systems as they are the primary raw material. These coils are unwound and fed into a roll forming machine, where they are shaped into the desired profiles and lengths. The steel framing systems, including studs, tracks, and joists, are then fabricated from these formed coils, providing structural support and stability to buildings and structures.

- Q: How are steel coils straightened?

- Steel coils are straightened using a process called leveling. This involves passing the coils through a series of rollers that gradually flatten and align the steel, resulting in straightened coils.

- Q: Are steel coils recyclable?

- Yes, steel coils are recyclable. Steel is a highly recyclable material, and steel coils can be melted down and reused in the production of new steel products, reducing the need for virgin materials and conserving resources.

- Q: What are the different surface treatments for steel coils?

- Steel coils can undergo various surface treatments to achieve different outcomes and applications. Some commonly used treatments include: 1. Hot-dip galvanizing: Steel coils are immersed in molten zinc, which forms a protective layer on the surface. This treatment provides excellent corrosion resistance for outdoor use. 2. Electro-galvanizing: A thin layer of zinc is electroplated onto the steel coils. It offers good corrosion resistance and is suitable for indoor applications. 3. Powder coating: Dry powder is applied to the surface and heated to form a durable coating. It provides excellent corrosion resistance and comes in different colors and finishes. 4. Paint coating: Steel coils can be coated with liquid paint, offering both corrosion resistance and aesthetic appeal. The thickness and finish can be customized according to the desired look and level of protection. 5. Phosphating: Steel coils are immersed in a phosphate solution, creating a thin layer that enhances paint adhesion and improves corrosion resistance. 6. Chromate conversion coating: Steel coils are immersed in a solution containing chromium salts, providing excellent corrosion resistance and acting as a primer for subsequent paint or powder coating. 7. Zinc-nickel plating: A layer of zinc-nickel alloy is electroplated onto the steel coils, offering superior corrosion resistance compared to pure zinc plating and is suitable for demanding environments. These are just a few examples of the many available surface treatments for steel coils. The choice depends on factors such as application, desired corrosion resistance, aesthetic requirements, and budget. It is important to carefully consider project needs and consult with experts to determine the most suitable treatment.

Send your message to us

Best Quality Cold Roll Zinc Glvanizing Steel Coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 23 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords