B-XG Type Parallel Beam Structure Load Cell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

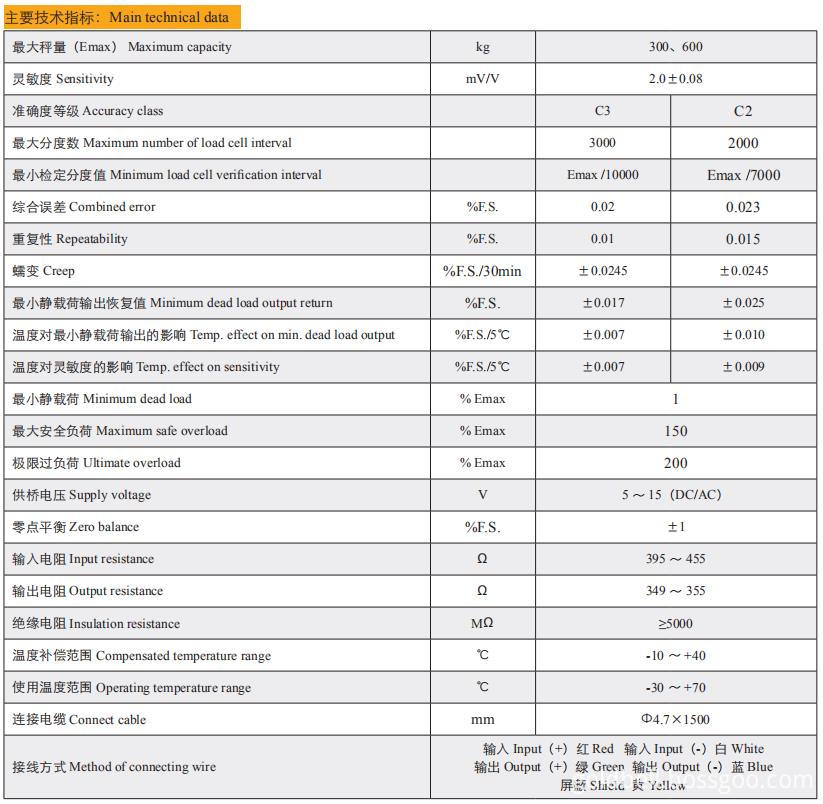

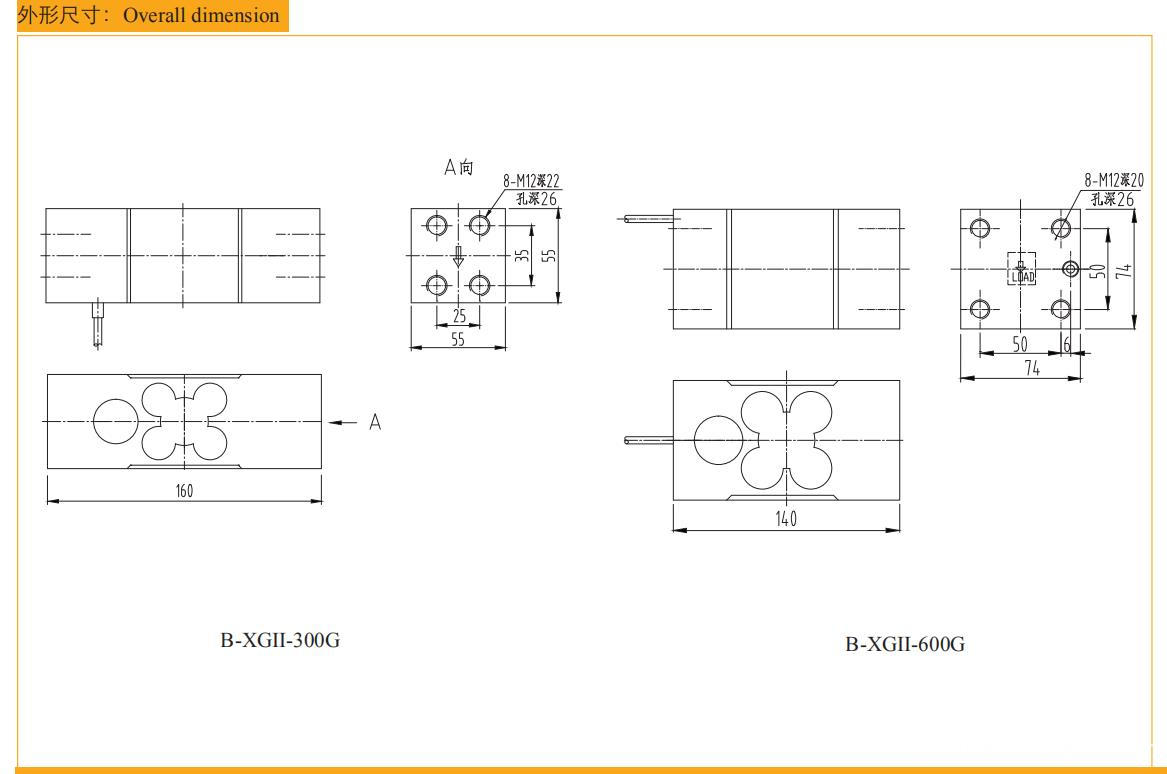

B-XG II -××G type load cell (made of alloy steel) is double parallel beam type with small size. The load cell (made of aluminum alloy) is double holed parallel beam type. It is through technology treatment of temperature compensation and adjusting four-corner error. It has low height and small size. It has been conducted four corners adjustment, has good anti-tilting-load, easily for installation and use.

The load cell has high quality and performance, long-term stability and safety. Our company uses the load cell in own platform scale and bench scale, and exports the load cell to various countries such as South Africa, Thailand, Indonesia and Phillipine.

It is suited to produce electronic price computing scale, electronic counter scale, electronic platform scale and other electric scales with small capacities.

The load cell has protection grade specified as IP67. It is able to be used in explosive dangerous circumstance, the explosion-proof symbol is Exia II CT6Ga; ExiaD20T85.

,

- Q: How to draw a pressure sensor in the hydraulic diagram

- It depends on your drawing. Is it a cutaway view or a circuit diagram? Ambiguous question

- Q: The intake manifold absolute pressure sensor is broken. What will happen to the car?

- Air flow can not be measured, will cause mixed gas dilution or too strong, knock will occur.

- Q: BYD F3 how to remove air pressure sensors

- It is easy to use the 8# sleeve or board just behind the throttle. This is very simple. Just what problem do you need to take out?

- Q: I use the analog module of Delta PLC, the signal of the sensor is 4-20mA standard signal, I received by PLC module is 0-20mA, how do I deal with, I consider a method, calculate the 4mA value of PLC is lower than this value, the value of the case, only, don't know I hope you handle this situation, the exchange, thank you

- You set the maximum range of 4-20mA in PLC, assuming that 100, then 4mA corresponds to 0, 0 Ma corresponding to -25

- Q: Druck (Drucker) how the pressure transmitter _ pressure sensor product quality, which Shanghai company agent of the product?

- Our company is also in use, the stability is good, although expensive point, I still recommend you use Druck (Drucker) pressure transmitter

- Q: A power positive, a power negative, a signal line, output 4 to 20 mA current, how to receive the signal line PLC?

- Pressure sensor output signal is 4-20mA, usually two wire system, it can not be 3 lines! The output of the 3 wire is a voltage signal

- Q: What are the sensors for measuring pressure?

- What you see is measured, the choice of diaphragm is not the same, the pressure transmitter, Beijing Wilvo, contact me, xuanggong

- Q: Automobile tire pressure sensor principle is how to work ah? Some cars don't have sensors installed in the tire valve. How do you detect low pressure? How do you monitor and alarm automatically?

- Detection principle1 、 direct tire pressure monitoringDirect tire pressure monitoring device is the use of pressure sensors installed in each tire to directly measure the tire pressure, using a wireless transmitter will send information from the tire to the central receiver module, and then the tire pressure data display. When the tire pressure is too low or leak, the system will alarm automatically.2 、 indirect tire pressure monitoringThe principle of indirect tire pressure monitoring is that when the pressure of a tire is lowered, the weight of the vehicle will reduce the rolling radius of the wheel, causing its speed to be faster than that of other wheels. By comparing the speed difference between the tires, to achieve the purpose of monitoring tire pressure. The indirect tire warning system actually monitors the air pressure by calculating the tire rolling radius.There are two main solutions to the tire pressure monitoring system, the direct system and the indirect system.Direct tire pressure monitoring system is the direct measurement of tire pressure by the pressure sensor is installed in every tire in, and the tire pressure display and monitoring, when the tire pressure is too low or when there is leakage, the system will automatically alarm.The indirect tire pressure monitoring system uses the wheel speed sensor of the automobile ABS system to compare the speed difference between the tires to achieve the purpose of monitoring the tire pressure:1, can not display accurate instantaneous pressure value of each tire;2, the same axle or the same side of the wheel or all tire pressure drop at the same time, can not alarm;3, can not take into account both speed, detection accuracy and other factors.

- Q: How to check whether the pressure sensor is normal or not?

- 1, no pressure power, test zero output is normal; 2, the pressure power to see whether the output changes. Normally, the sensor is normal, otherwise the sensor is damaged!

- Q: An instrument on the SMC pressure sensor will not be adjusted, the instructions do not understand too much, simple and clear instructions to adjust the pressure step.For example, only after opening out1 and adjusting the P-1 and P-2, how does the display pressure come from, and how can I get the pressure I want?

- Today, I happen to meet the debug SMC digital pressure reducing valve:There are three buttons on the panel: up, S (set) and downFirst press "S" to enter the setting mode, it will show "P1" or "N1", P1 is the ordinary output mode, N1 is an alternate output, and you have only one out1, only P1, N1 can ignore, ignoreP1 and a value alternately flashing, this is to press up, down key, adjust this value size, this value is our set value, for example, 5 bar is greater than this value, there is outputWhen the settings are complete, press the "S" button to complete the settingsIf there are two output out2, then set P2 or N2, none will be ignoredThen press "S" to appear "P1H" or "P1L", and a value, which is setting the upper and lower tolerances, such as 0.5 bar, which means that 4.5bar has outputIf you press "S" for more than 2 seconds, you go to the function setting "F0". "F1". Generally speaking, this doesn't work. Just one "F0" is fine. Ignore it anywayIf you see "HYS" is "hysteresis" means, that is greater than 5,0bar, there is an output, but if there is a leak, the pressure reduced to 4.5bar, there are outputsIf at the same time press "up", "down", about 1 second, will be cleared, the pressure clearedThe pressure shown is the pressure of the current pipeline. Take the top cover of the pressure reducing valve out and turn it clockwise. The pressure changes. Transfer to the pressure you need and press the top cover back

Send your message to us

B-XG Type Parallel Beam Structure Load Cell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords