Full-automatic pressure testing machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The testing machine is mainly used for brick, stone, cement, concrete and other building materials, compressive strength test.

Production Summary:

300kN/10kN Full-automatic resist bending compression testing machine is mainly used for brick, stone,

cement, concrete and other building materials, compressive strength test.

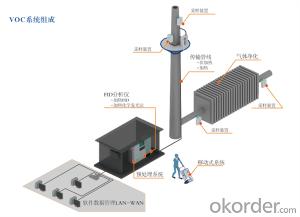

Hydraulic System:

The hydraulic oil tank driven by high-pressure pump into the motor oil, flows through the unidirectional valve,

high pressure filter, pressure valve, servo valve, into the cylinder.Computer control signals to the servo valve.

Control direction and opening of the servo valve ,to control the flow into the cylinder,achieve constant test

force control.

Control System:

System including digital servo valve, high-precision sensors, controllers and software, high control precision

and reliability.Meet GB, ISO, ASTM and other standards for cement, mortar, concrete and other materials

testing requirements.

System Has The Following Functions:

Closed-loop control with force;

Can achieved constant loading rate or constant stress loading rate;

Adopt computer for electronic measurement, automatic test;

Computer automatically calculates the results and print reports.picture 1 picture 2

Test reports can be to self-design and exported to Excel picture 3

Safety Protection Device:

When the test force more than 3% of the maximum test force, the overload protection, oil pump motor shut down.

Main Performance Technical Specification:

Model | HZ-008 Full-automatic resist bending compression testing machine |

Max load | 300kN/10kN |

Test force measuring range | 4%-100%FS |

Test force showed the relative error | ≤indicating value±1% |

Test force resolution | 0.01kN |

Hydraulic pump rated pressure | 25 MPa |

Loading rate | 0.3KN/S~10KN/S |

Error loading speed | ±5% |

Pump rated flow | 1.52L/min |

Upper and lower bearing plate size | φ155mm |

Maximum distance between the upper and lower plate | 260mm |

Piston diameter | φ130mm |

Piston stroke | 60mm |

Motor power | 3 phase 0.75 kW |

Outside dimension | 870×450×1400mm |

Weight | 450Kg |

- Q:Band sawing machines sometimes fail to rise, sometimes very slowly, and sometimes pressure gauges have no pressure

- There is no oil in the hydraulic system

- Q:Is the gauge thread metric or English?

- In domestic engineering, gauges generally use metric threads, such as M20*1.5, with M14*1.5 or M10*1 threads on some small gauges. In addition, some items may use inch threads, such as G1/2, small table diameter, G1/4 or G1/8. The above two are straight thread, is the end seal, installation needs to choose different gaskets according to different conditions. In addition, some use NPT thread by joint venture or foreign patent project, commonly used is 1/2 NPT, a small table size with 1/4 "NPT" NPT, 1/8, rarely used this is American Standard thread cone type buckle. This thread by thread sealing, without gasket. Domestic often winding Teflon belt, because the domestic NPT fastener processing accuracy is not high. The commonly used table diameter is 100150mm, and the small caliber is below 63mm.

- Q:Cutting acetylene bottles on how there are 2 pressure gauges, which is an adjustable, adjustable number, and oxygen. Thank you!

- The acetylene pressure reducing valve is provided with two tables, an air inlet and outlet, a pressure reducing mechanism and a fastening structure,Which is near the inlet of the high-pressure meter, measuring the pressure in the bottle, the numerical value of larger, 0-2.5 bar. Opening the valve of the bottle will cause pressure.Near the outlet of the low pressure table is cut (cutting) pipe pressure, the small number of 0-0.5.Usually use the first bottle to open the valve two laps, in the pressure reducing valve, low pressure meter to about 0.03, enough for 1 cm or so steel plate cutting.

- Q:How do remote pressure gauges receive frequency conversion?

- [1] inverter 10V, VF, GND point is the voltage control frequency of external contacts, is not directly connected to other signals, and can not be defined as other functions, in addition to voltage signals. As for the remote pressure gauge, one is divided into upper and lower limit, switch signal output, (also an instant signal, leaving the lower limit pointer is disconnected, cannot keep) called electric contact pressure gauge; there is no so-called resistance output, the upper and lower limit, through the pressure controller or by the PG board needs to transform into a voltage or current signal to control the frequency converter. Therefore, the remote pressure gauge can not be directly in the inverter 10V, VF, GND points, you need to control the inverter through some means.[2]: pressure gauge pressure gauge (English Name: pressure gauge) refers to the elastic element as the sensitive element, measuring and indicating higher than ambient pressure meter pressure gauge installation of Shanghai Wang ring is widely used, it almost all the industrial processes and scientific research. In the heat pipe network, oil and gas transmission, water supply system, vehicle repair and maintenance shop, and other fields can be seen everywhere. Especially in the control and measurement process, because the elastic sensitive element of mechanical pressure gauge has the characteristics of high mechanical strength and convenient production, the mechanical pressure gauge is widely used.

- Q:What is the function of the pressure gauge bend?

- The formal name of the table bend is called the buffer tube, which mainly has the function of reducing shock and shock. It can also play a certain role in heat dissipation of the medium with higher temperature, and protect the pressure gauge and reduce the temperature of the pressure gauge to affect the error. The damping screw at the orifice of the part of the pressure gauge has a throttling effect by reducing the flow area. Mainly useful for medium pressure pulses.

- Q:What pressure gauges are used in a pressure vessel?

- Under normal circumstances, the use of 0-0.1Mpa range of pressure gauges. If the pressure is small, you can use the Kpa table

- Q:In which industry does the pressure gauge use more?

- Oil and gas extractionoil refiningPetrochemical and chemical industrypowerwater treatmentPapermakingsteelPharmacyfood

- Q:How do you see a vacuum gauge?

- The units on the vacuum pressure gauge are bar, MPa, kPa, and the readings are mainly visible;The vacuum meter is divided into pressure vacuum meter and vacuum pressure gauge. Vacuum pressure gauge: Instrument Based on atmospheric pressure for measuring less than atmospheric pressure. Pressure vacuum meter: an instrument based on atmospheric pressure for measuring greater than or less than atmospheric pressure.There are two ways of expressing pressure. One is the absolute pressure, which is called absolute pressure, and the other is the pressure expressed on the basis of atmospheric pressure, which is called relative pressure. Since the pressure measured by most pressure gauges is relative pressure, the relative pressure is also called the gauge pressure. When the absolute pressure is less than the atmospheric pressure, the absolute pressure in the container is less than the value of one atmospheric pressure. Vacuum".They are as follows: the relationship between the absolute pressure = + atmospheric pressure relative pressure; vacuum degree = atmospheric pressure and absolute pressure; pressure units in China legal Pa (N/ m), known as Pascal, referred to as the PA. Since this unit is too small, it often uses its 10^6 times unit MPa (Zhao Pa).

- Q:How is the pressure gauge ABC divided?

- Pressure gauges belong to the category of safety protection, which belong to strong inspection items. According to the JJG52-1999 test procedure, the cycle is half a year.Enterprises may, according to the specific circumstances used, determine the test cycle by A/B/C.Class A is compulsory test, which is related to production safety and environmental monitoring. The test cycle must be only less than half a year according to the verification regulations. If the conditions are bad, the verification cycle must be shorter.The B class should in principle not exceed the requirements specified in the verification regulations.The C class can determine the cycle of verification according to the characteristics of the enterprise, but there should be a square for determining the period of verification

- Q:The difference and relation between the electric contact pressure gauge and the remote pressure gauge

- The use of the two is different. One is used to control the other, and the other is to send the signal to the farther end of the monitor.The electric contact pressure gauge consists of measuring system, indicating system, magnetic auxiliary contact device, shell, adjusting device and junction box (plug seat), etc.. The working principle of electric contact pressure gauge is spring pipe in the measuring system under the action of the pressure of the measured medium based on the force generated by the end of spring pipe corresponding elastic deformation displacement transmission rod through a gear transmission mechanism with the help and amplification by the fixed gear instructions (along with contact) by the measured value indicated in the table. At the same time, when the contact and set on the pointer (upper or lower) contact (break or close) instantaneous, resulting in the circuit control system can be switched on or off in order to achieve the purpose of automatic control and alarm.The remote pressure gauge is suitable for measuring the pressure of liquid, steam and gas which can not corrode the steel and copper alloy. Because the resistance transmission pressure gauge is arranged inside the sliding line resistance transmitter, so the measured values of two meters on electricity to far away from the measurement, in order to realize centralized monitoring and remote control. In addition, the pressure gauge is capable of indicating pressure in place so as to facilitate on-site inspection.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Full-automatic pressure testing machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords