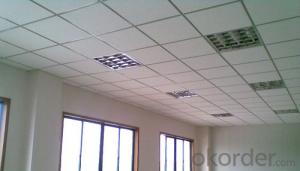

Astral Mineral Fiber Board False Ceiling

- Loading Port:

- Xingang China

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 1×40HQ m²

- Supply Capability:

- 20000 m² per day m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

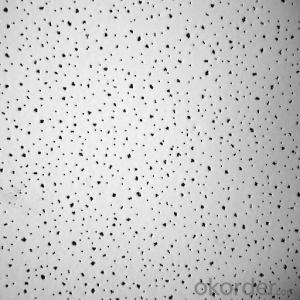

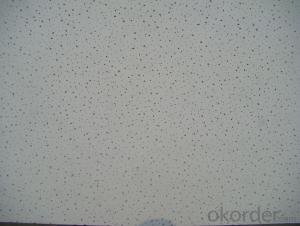

Standard Size: 595mm*595mm, 605mm*605mm

Standard Thickness: 8, 9, 10, 12, 14, 15mm

Edge Detail: Square Edge, Tegular Edge (≥12mm)

Technical Data of Acoustic Mineral Fiber Ceiling:

Density: 260-320kgs/m3

NRC: ≥0.50

Fire resistance: Class B1 (standard GB 8624-1997)

Moisture rate (%): ≤3.5 (40℃,70%RH)

Light reflect: 0.70-0.80

Sagging resistant properties: ≤0.35mm

Humidity Resistance: ≥85%

Main advantages of Acoustic Mineral Fiber Ceiling:

Wonderful sound-absorption

High humidity resistance properties

Excellent light reflectance

Environment-friendly

No content of asbestos

Zero release of CH2O

Economical Choice

Standard Thickness: 8, 9, 10, 12, 14, 15mm

Edge Detail: Square Edge, Tegular Edge (≥12mm)

Technical Data of Acoustic Mineral Fiber Ceiling:

Density: 260-320kgs/m3

NRC: ≥0.50

Fire resistance: Class B1 (standard GB 8624-1997)

Moisture rate (%): ≤3.5 (40℃,70%RH)

Light reflect: 0.70-0.80

Sagging resistant properties: ≤0.35mm

Humidity Resistance: ≥85%

Main advantages of Acoustic Mineral Fiber Ceiling:

Wonderful sound-absorption

High humidity resistance properties

Excellent light reflectance

Environment-friendly

No content of asbestos

Zero release of CH2O

Economical Choice

- Q: How to use the wall decoration board

- The use of decorative wall panels is simple, generally do not need special technology to operate. The size of the entire decorative plate is 2440 mm × 220 mm. Install the first size according to the design of cutting, the board cut into the required specifications, the cutting point must be straight. The wall and decorative panels on the back of the brushing adhesive, pay attention must be fully coated, do not have the part of the brush, the wall should be pre-play a good control line pavement, compaction, until the adhesive dry hard, with silicon Patching or pressing. There is the mouth of the decorative plate width of 90 mm or l65 mm, the length of the general 2440 mm, should be used vertically, the installation should first press the design size of the material, the need for parquet should be cut on the flower after the puzzle Cutting. Before installation, the wall and the back of the board should be coated with adhesive, the adhesive in the upper, lower and middle parts can be painted, the installation of vertical compaction compaction, until the adhesive dry, with wood line pressure side closure. After installation of the wall decoration board, it is necessary to clean the extruded glue in time to prevent contamination of the board. Wall decoration board can be used after installation, no need to paint varnish and other surface decoration. Wall-mounted decorative panels are required to be flat, hard, clean and dry, and the treatment is the same as the wooden dado.

- Q: for example im doing a science fair project and the expirement involves a surface of a book a plate and and the materials that complete the experiment are a loud clicking clock and two paper towl tubes and the sound should go through the tube and bounce off the book (plate) and go through the second tube.

- Hard flat smooth surfaces like marble walls.

- Q: The wall decoration board that brand is good

- In the choice of decorative panels, mainly from the following aspects to consider: 1, from the color on With the development of the decoration industry, decorative panels endless, less talk about the market there are hundreds of colors to choose from, in the selection of a lot of room to see the color of the eye is also a lot, but it is impossible to see all the Sell ??home, in the choice of decorative panel color should be considered their own wooden floor color, has been fancy furniture color, sofa color, etc., there is a whole harmony with the color will be more taste, can not just look at the color of the model look good , But can not and their own home furnishings of other words, is a flaw. 2, the quality of the plate Not the sooner the board is a good board, not to say that the production is not a good board, Kanban can not just look at the price level, and some plate although the price is very low, but because it is mature products, often quality But more superior, take Thai pomelo yellow, for example, only when the time to more than sixty, only half a year, more than thirty can buy, and the plate sandwich compared to the original good, it is because with the development of time , Its production process is also improving, the product is more and more mature, the market price transparency is also higher and higher, the natural price will be down. 3, the price on Plate is not the higher the price, the higher the quality, so the choice of decorative panels to consider when the price. Decorative panels are multi-layer veneer criss-cross arranged from the combination of sheet metal. The outermost front panel is called a panel, and the back is called a backplane. The inner board is called the core plate.

- Q: How to install aluminum alloy decorative panels?

- Aluminum alloy decorative plate varieties, specifications and colors by the design Lai Ding, generally by the vertical installation of the board on the wall. Install the aluminum alloy decorative panels of the wall to be done in advance 15mm thick 1: 3 cement mortar leveling layer. To be cement mortar leveling layer after hardening, 500mm per hole in the wall drilling, aperture of about lOmm, in order to plug the steel expansion bolts. Ready to keel, keel can be cold-formed actinized keel or aluminum alloy keel, keel height is appropriate 60mm, width is appropriate 30mm wall thickness 2.5mm. Punch holes in the keel. When the keel is installed, insert the steel swivel bolt into the wall and drill the keel Hole into the bolt, add nuts and washers, tighten the nut, the keel fixed to the wall. The keel should be installed horizontally. Keel installation by checking the correct, you can install the aluminum alloy plate to the keel up. Aluminum alloy decorative plate fixed on the keel method can be used M4 × 6.5 aluminum alloy pull rivets (plus steel card) or use M4 × 15 tapping screws. Aluminum alloy decorative panels should be installed vertically, the board and the keel contact, at least have a pull rivets or tapping screws fixed.

- Q: I now the wall is a white wall, the formation is not the first must be fixed before the wooden side of the wood panel with a fixed panel or you can omit the wooden side of the solution to understand the brother to thank you

- Decorative panels are fixed on the woodworking board, white latex plus mosquito nails, wall facade must have wooden stalls, wood stalls and then fixed woodworking board, so solid, can not be omitted, the general is the case, but specific You have to ask the carpenter.

- Q: Decorative panels for exterior wall trim panels

- Decorative panels are made in recent years by the new building exterior decoration insulation materials; the material from the polyester paint or fluorocarbon paint, carved aluminum zinc alloy steel plate, polyurethane insulation layer, glass fiber cloth compound made of the main application In the gymnasium, library, school and hospital office buildings, villas and other buildings of the external walls of decorative and energy-saving transformation; the main function for the building decoration, thermal insulation, heat insulation, waterproof and mildew. Metal surface decoration insulation board is the industrial production of large format plug-in wall panels, dry installation, durability, low maintenance costs, set the external wall insulation and decorative functions in one, in line with building energy efficiency "modular" technology development, Is China's building wall insulation technology to promote the field of an advanced technology.

- Q: Where do you buy a decorative plate made of diatom?

- Using high-temperature coating technology one-time molding, a little smell are not, good decoration can stay.

- Q: Does the decorative plate contain formaldehyde?

- Plywood formaldehyde grade all products can reach e1 level and E0 level, and wholesale plywood to consider to his house to see it! Good manufacturers, operating for 20 years

- Q: Energy-saving insulation decorative plate prices

- Energy-saving insulation decorative board is a multi-characteristics of the composition of the plate, more suitable for home use fire board ah, or insulation board, the main price is 1 / block; 1, Fluorocarbon metal paint finishes series structure : Vacuum insulation board / XPS / EPS / rock wool / phenolic insulation board + inorganic resin plate + Fluorocarbon metal paint matching products. 2, polyurethane metal lacquer finish series structure: vacuum insulation board / XPS / EPS / rock wool / phenolic insulation board + inorganic resin board + polyurethane metal paint matching products. 3, Fluorocarbon solid paint finishes series structure: vacuum insulation board / XPS / EPS / rock wool / phenolic insulation board + inorganic resin plate + fluorocarbon solid paint (multi-color choice) matching products. Features: high-grade decorative effect, with ultra-durable protection, energy efficient and environmentally friendly, high weather resistance, high self-cleaning, anti-pollution, acid rain, strong adhesion, compactness, low cost 4, polyurethane solid paint finishes series structure: vacuum insulation board / XPS / EPS / rock wool / phenolic insulation board + inorganic resin board + polyurethane solid color paint (multi-color choice) matching products. Features: high-grade decorative effect, with ultra-durable protection, energy efficient and environmentally friendly, high weather resistance, pollution resistance, acid rain, strong adhesion, compactness, low cost.

- Q: Seeking Haver M2 car door trim panels demolition methods, as well as the door inside the door demolition method, for detailed tutorial.

- And then a glass edge of a triangle trim board unloaded, and then pull out the door can be a vertical

Send your message to us

Astral Mineral Fiber Board False Ceiling

- Loading Port:

- Xingang China

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 1×40HQ m²

- Supply Capability:

- 20000 m² per day m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords