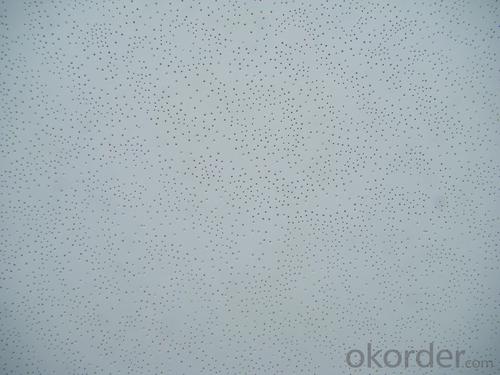

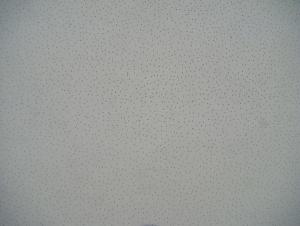

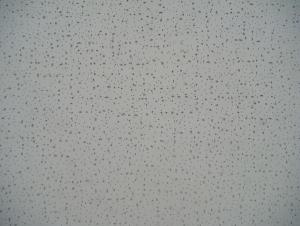

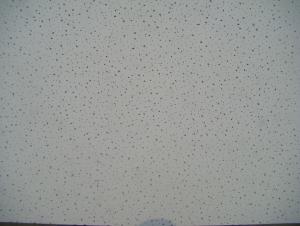

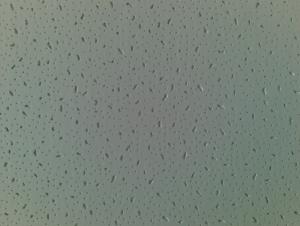

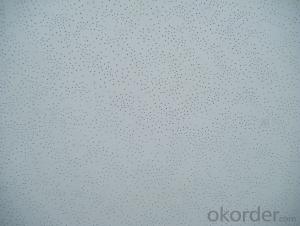

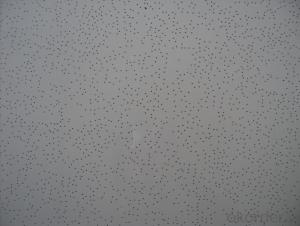

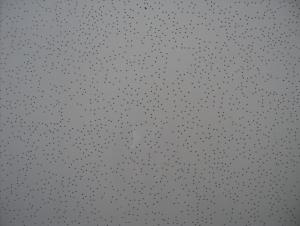

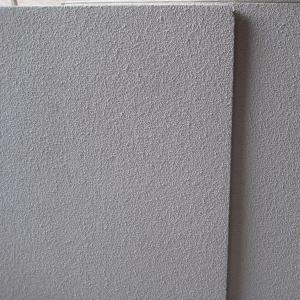

Mineral Fiber Grid Ceiling - MP03

- Loading Port:

- Xingang China

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 1×40HQ m²

- Supply Capability:

- 3×40HQ per day m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Standard Size: 595mm*595mm, 605mm*605mm

Standard Thickness: 9, 10, 12, 14, 15, 18mm

Edge Detail: Square Edge, Tegular Edge (≥12mm)

Technical Data of Mineral Fiber Ceiling:

Density: 260-320kgs/m3

NRC: ≥0.50

Fire resistance: Class B1 (standard GB 8624-1997)

Moisture rate (%): ≤3.5 (40℃,70%RH)

Light reflect: 0.70-0.80

Sagging resistant properties: ≤0.35mm

Humidity Resistance: ≥85%

Typical Application Areas of Mineral Fiber Ceiling:

Hotel Lobbies and Corridors

Offices and conference rooms

Department stores

Super Malls

Hospitals and other Public areas

Standard Thickness: 9, 10, 12, 14, 15, 18mm

Edge Detail: Square Edge, Tegular Edge (≥12mm)

Technical Data of Mineral Fiber Ceiling:

Density: 260-320kgs/m3

NRC: ≥0.50

Fire resistance: Class B1 (standard GB 8624-1997)

Moisture rate (%): ≤3.5 (40℃,70%RH)

Light reflect: 0.70-0.80

Sagging resistant properties: ≤0.35mm

Humidity Resistance: ≥85%

Typical Application Areas of Mineral Fiber Ceiling:

Hotel Lobbies and Corridors

Offices and conference rooms

Department stores

Super Malls

Hospitals and other Public areas

- Q: Uvp decorative plate for home improvement?

- Hello, uv board decoration is not suitable for home improvement, the general applies to bars, high-end mall, villas and ktv!

- Q: I'm trying to write a report about asbestos insulation and other then the fact that it causes cancer, I cannot find much, any information is greatly appreciated!

- go to this web site for the various types of asbestos. The blue one at the bottom is the bad guy.

- Q: Bamboo fiber integrated wall decorative plate is what structure

- 2017 is the beginning of the day with the United States with aluminum foil, foam layer, made of aluminum alloy, 2017 days of the United States integrated wall decoration materials used to upgrade to bamboo fiber, polymer waterproof fire materials, spar powder high temperature suppression, Using high temperature coating or roller coating process, very environmentally friendly and beautiful, with a very good market demand.

- Q: Fatal bug in integrated wall!

- If you unfortunately choose aluminum alloy wall as a decorative wall, then the electric shock will be inevitable. As the decoration power supply is now a lot of excuses, Insulation is normal, but if exposed to aluminum, it will cause fatal problems! Electric shock dead is normal.

- Q: This year more popular polymer UV decorative board, this material has any shortcomings?

- Polymer plate in a lot of years ago have a similar product, after the gradual upgrading of technology, building materials used in general is the plastic polymer, the fire performance is a never hide the problem, which makes it in many large places , The public environment and even the use of home improvement will be limited, but also consumers need to pay attention to the place of purchase.

- Q: Excuse me where to dig decorative panels ah? Not a splint. I do not have one at all

- 30 blue tickets to buy the crystal hole in the three colors of the marble are out of the decorative plate, dug a decorative plate, in fact, the number is three

- Q: Do you want to burn the antique stone composite panel

- Speaking of the area may be easier to answer

- Q: How to remove the Chery a3 shift to twice the plastic decorative panels

- Hello, the side has a screw. Seat can be seen before and after the move

- Q: What is the color quartz sand decorative plate?

- Color quartz sand decorative plate is a white cement or colored cement as a cementing material, with natural colored stones, colored quartz sand, or workers to synthesize colored particles as aggregate, mixed with ingredients casting molding, water brush after the maintenance of stripping, Of the plate.

- Q: I go to a small and very old college in western Pennsylvania. My dormitory is about 70 years old. There are rumors that the walls are "filled with asbestos". I don't know much about this, but what are the odds that there is some truth to this rumor, and why exactly is asbestos harmful?

- Most of the universities and colleges throughout the country are filled with asbestos. It's just a fact of life. One time I was walking down a hallway and an asbestos ceiling tile was lying on the ground because it had fallen from the ceiling. I gasped and held my breathe as I walked by. How many people do you think were exposed? That's a low level exposure and what we experience everyday. Every time you are out driving in traffic you are being exposed to low levels of asbestos because asbestos was used in automobile fiction parts. Asbestos is harmful because it's a mineral that breaks down into tiny fibers that get into your lungs causing irritation and later cancer. If you breathe in one too many of these fibers you can contract a deadly disease called mesothelioma. It's dangerous stuff and massive exposures should be avoided at all costs.

SERENITY,is a large company which produces light mineral wool acoustic board. It displays a good combination of production , manufacture, supporting sales and international trade.Its products cover more than twenty varieties of six categories, including knurling board, relief-embossing board, printing board, spraying board, stereo-molding board, etc.

1. Manufacturer Overview

| Location | Jinzhou,China |

| Year Established | 2006 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Japan, Italy, South- Africa ,India, Russia, Malaysia, Singapore, Taiwan and other countries and areas |

| Company Certifications | ISO9001-2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | TIANJIN |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Mineral Fiber Grid Ceiling - MP03

- Loading Port:

- Xingang China

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 1×40HQ m²

- Supply Capability:

- 3×40HQ per day m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords