Anti-Slip Tape with Aluminum Base for Boxes - Packaging Tape for Sticking Pads

- Loading Port:

- Shanghai

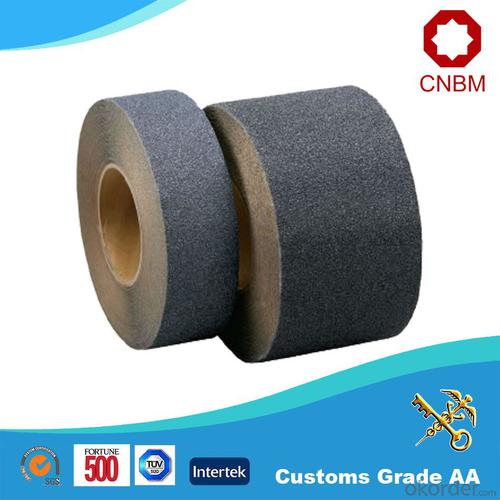

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

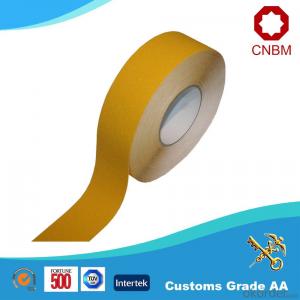

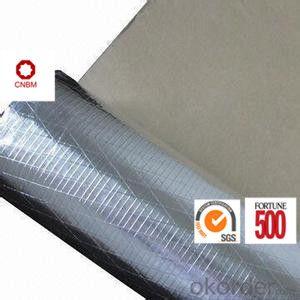

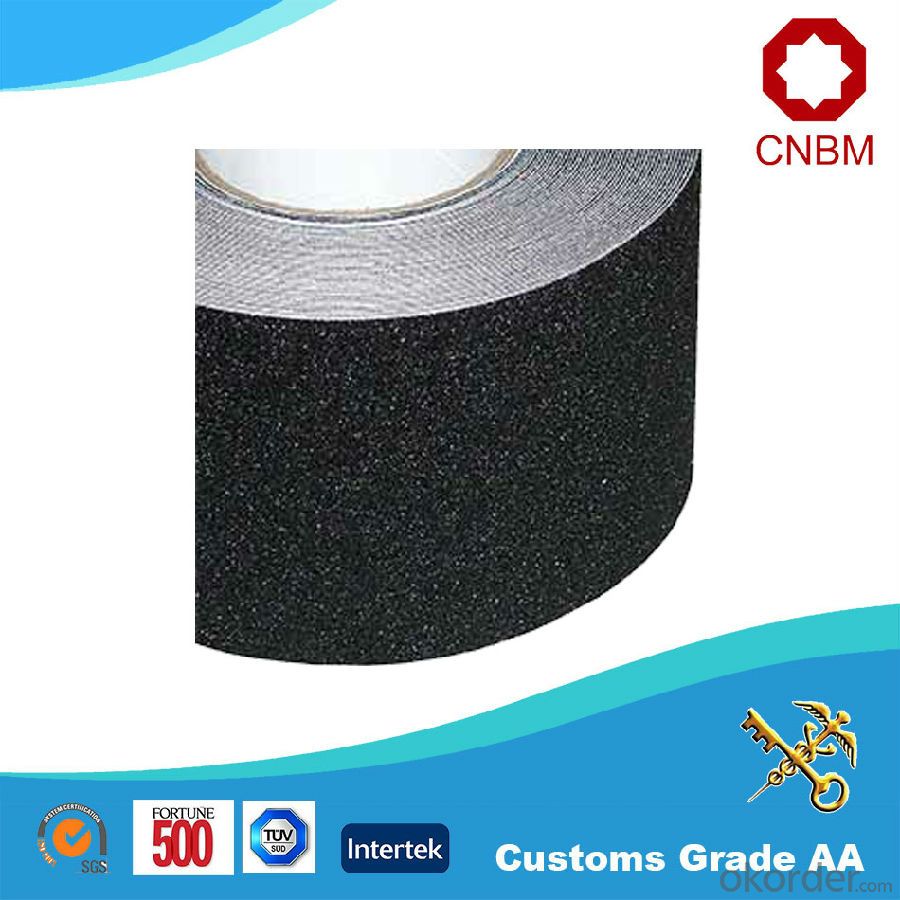

Anti-slip Tape with Aluminum Base for Sticking Pads

1. Structure of Anti-slip Tape Description

This Anti-slip Tape is of Aluminum as based, ready-to-use waterproof strong viscose as glue. Sticking pads with aluminum bases are recommended to be applied on the irregular arched surfaces.

2. Main Features of Anti-slip Tape

- Irregular Surface

SGS and ISO9001

Printing Patterns

High mechanical strength

Excellent in adhesion

Resistance to age

3. Anti-slip Tape Images

4. Anti-slip Tape Description

Item No. | Carrier | Thickness (c) | Anti-skid sand | Surface granularity |

CN-1107 | PVC film | 15 | black corundum | 50 items |

CN-1108 | PVC film | 10 | silicon carbide | 60 items |

CN-1109 | PET film | 5 | white corundum | 80 items |

CN-1111 | PET film | 5 | silicon carbide | 80 items |

CN-1113 | PP film | 5.6 | white corundum | 120 items |

CN-1114 | PP film | 5.4 | white corundum | 80 items |

CN-1116 | PP film | 5 | white corundum | 60 items |

5. FAQ

Q1. What is our company?

CNBM International Corporation is a state-owned company. As World Top 500 Company, we have clients from over 120 countries and overseas branches in 5 countries. We specialized in adhesive tape for over 20 years, with SGS and ISO9001 certified and Grade AA for Export.

Q2. What can we do for you?

24 hours service for you

Custom-made advices for your need

Satisfactory sales service

Professional consultation on your local market

Your inquiry will be replied within 12 hours.

Q3. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Does packaging tape come in different finishes or textures for aesthetic purposes?

- Yes, packaging tape does come in different finishes or textures for aesthetic purposes. While the primary function of packaging tape is to securely seal boxes and packages, manufacturers have recognized the importance of aesthetics in packaging. As a result, they have developed packaging tapes with various finishes and textures to meet different aesthetic preferences. Some packaging tapes come in glossy finishes, which can give a more polished and professional look to the package. These tapes often have a smooth and shiny surface that reflects light, making the package appear more visually appealing. Glossy packaging tapes are commonly used in industries that require a high-end presentation, such as luxury goods or high-quality products. On the other hand, there are also packaging tapes with matte or satin finishes. These tapes have a more subtle and refined appearance, providing a sophisticated look to the package. Matte or satin tapes are often favored in industries that value a more subtle and understated aesthetic, such as cosmetics or boutique products. Apart from finishes, packaging tape can also come in different textures. For example, some tapes have a textured or patterned surface, which adds a tactile element to the packaging. These tapes can have embossed patterns, such as dots, stripes, or even company logos, which can enhance the overall visual appeal and uniqueness of the package. In summary, packaging tape does come in different finishes or textures for aesthetic purposes. Whether it is a glossy, matte, satin, or textured surface, these variations allow businesses to choose packaging tape that aligns with their branding and desired presentation. By utilizing different finishes and textures, packaging tape can not only serve its primary function but also contribute to a more visually appealing and customized packaging experience.

- Q: Is packaging tape safe to use on painted furniture?

- Packaging tape is generally safe for use on painted furniture, but it's important to consider a few factors beforehand. Firstly, make sure the furniture's paint is fully cured or dried, as tape on fresh paint can cause peeling. Additionally, check the type of paint used, as certain types may be more susceptible to damage or discoloration from adhesive tape. To be cautious, test the tape on a small, hidden area of the furniture to check for any damage. It's also advisable to remove the tape slowly and carefully to minimize the risk of harm.

- Q: Can packaging tape be used for sealing automotive parts or equipment?

- Sealing automotive parts or equipment with packaging tape is generally not recommended. Packaging tape is designed for securely sealing lightweight materials like cardboard boxes, but it may lack the durability and adhesive strength necessary for automotive use. Automotive parts and equipment experience various conditions like heat, vibrations, and exposure to chemicals, which can degrade or weaken packaging tape over time. Furthermore, specialized sealing methods like gaskets, seals, or automotive-grade adhesives are typically required for proper functionality and long-lasting performance. Therefore, it is generally advisable to use sealing methods and materials specifically designed for automotive applications to ensure desired performance and reliability.

- Q: How do I prevent packaging tape from losing its adhesive properties?

- To prevent packaging tape from losing its adhesive properties, it is important to store it in a cool, dry place away from direct sunlight and extreme temperatures. Additionally, ensure that the surface where the tape is applied is clean and free from any dust, oil, or moisture, as these can compromise the adhesive. Applying the tape firmly and evenly, avoiding excessive stretching, can also help maintain its adhesive strength.

- Q: Is packaging tape resistant to chemicals or solvents?

- Yes, packaging tape is typically resistant to chemicals and solvents.

- Q: How is packaging tape different from regular tape?

- Packaging tape is specifically designed for sealing boxes and securing packages during shipping or storage. It is typically wider, stronger, and more durable than regular tape, making it capable of withstanding the rigors of transportation. Regular tape, on the other hand, is generally used for lighter tasks like wrapping gifts or hanging lightweight objects.

- Q: As for the title, just bought the tape cutter, but I don't know how to use it. I bought it in plastic. Used for packing express boxes. It's better to use a process chart for me to see.. Thanks。。 Or clear words can also...

- How do I fit the tape onto the sealing machine?There is no machine, or else let you have a look

- Q: What are the benefits of using reinforced packaging tape?

- Reinforced packaging tape offers several benefits, including enhanced durability and strength, making it ideal for securing heavy or bulky items during transportation. It minimizes the risk of package damage, breakage, or tampering. Its reinforced fibers provide extra resistance to tears and abrasions, ensuring the integrity of the package. Additionally, the tape's strong adhesive properties ensure a secure seal, reducing the chances of contents spilling or getting lost. Overall, reinforced packaging tape provides peace of mind, cost savings, and improved customer satisfaction.

- Q: General adhesive tape is a taste, the size of the taste depends on the formula of glue, low molecular weight content, taste will be larger, once adhesive tape, it has a very small taste tape, we have been using.

- The bubble is on the tape slitting machine when cutting the air into the tape to improve only by changing the type or sub machine will have a bubble for 1 months or longer, the bubbles will automatically eliminate, the premise is to increase the cutting of the tape tension, if loose, put a few day and bubble;

- Q: How does packaging tape perform on low-friction surfaces?

- Packaging tape generally does not perform well on low-friction surfaces. Its adhesive may struggle to stick firmly, leading to reduced adhesion and the tape easily peeling off. In such cases, it is recommended to use alternative adhesive solutions or methods specifically designed for low-friction surfaces to ensure proper packaging and sealing.

Send your message to us

Anti-Slip Tape with Aluminum Base for Boxes - Packaging Tape for Sticking Pads

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords