Anti-Rust Aerosol Can For Spray, Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 PCS

- Supply Capability:

- 30000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Brief description

Content: insecticide

Size: 52X195mm

Printing: CMYK printing as Per Customer Design

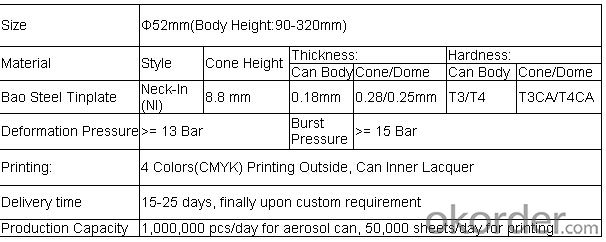

2.Detailed Specification

3. Usage:

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

4. Package:

5. Appearance Specifications

Diameter(mm) | Type | Straight(mm) |

45mm | Necked-in | 80-220 |

52mm | Necked-in | 80-300 |

52mm | Straight | 76-200 |

57mm | Necked-in | 90-240 |

60mm | Necked-in | 90-240 |

60mm | Straight | 80-300 |

65mm | Necked-in | 80-240 |

65mm | Straight | 80-240 |

6.FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s request

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q: What are the key properties of tinplate?

- Tinplate is characterized by its corrosion resistance, strong formability, and excellent storage stability, making it an ideal material for packaging applications.

- Q: How does tinplate perform in high-temperature applications?

- Tinplate performs well in high-temperature applications due to its excellent heat resistance and durability. It can withstand elevated temperatures without warping, melting, or releasing harmful substances, making it a reliable choice for various industrial and packaging uses.

- Q: What are the different types of tinplate edge finishes?

- There are typically three main types of tinplate edge finishes: open, closed, and inward rolled. The open edge is the most common and leaves the tinplate edge exposed, while the closed edge is formed by folding the edge of the tinplate under itself for a more finished appearance. The inward rolled edge is created by rolling the edge of the tinplate towards the inside of the can, providing a smoother and safer edge.

- Q: What are the different thickness options for tinplate?

- The different thickness options for tinplate typically range from 0.13mm (0.005 inches) to 0.49mm (0.019 inches), depending on the specific requirements of the application.

- Q: Advantages and disadvantages of tinplate packaging

- Because of these properties, so can provide a besides the heat, completely isolated from the closed system of environmental factors, avoid color food because of light, oxygen, moisture and deterioration, nor because of aroma through and become weak or affected by environmental pollution through the smell and taste, stability is better than that of other packaging materials of food storage. Vitamin C save the highest rate, nutrient retention is the best. International environmental management standards will be implemented soon based on ISO-14000, has the advantages of low pollution, tin recycling, resource characteristics, in the future packaging applications, will have a broader space for development.

- Q: How does tinplate contribute to the preservation of paint products?

- Tinplate contributes to the preservation of paint products by providing a durable and protective packaging solution. It is a corrosion-resistant material that prevents the paint from coming into contact with oxygen, moisture, and other external factors that can lead to degradation or spoilage. Additionally, tinplate cans are known for their tight seals, preventing any leakage or contamination that could compromise the quality and longevity of the paint inside.

- Q: How does tinplate perform in terms of oxygen barrier properties?

- Tinplate has excellent oxygen barrier properties, making it an effective material for packaging applications.

- Q: What are the common testing methods for tinplate?

- Some common testing methods for tinplate include visual inspection, thickness measurement, adhesion testing, corrosion resistance testing, and tensile strength testing.

- Q: What are the transportation considerations for tinplate?

- Transportation considerations for tinplate include ensuring proper packaging and securing the tinplate to prevent damage during transit. Due to its susceptibility to corrosion, tinplate should be protected from moisture and extreme temperatures. Additionally, the weight and size of tinplate may impact the choice of transportation method and require careful handling to prevent accidents or injuries.

- Q: What are the different ways to recycle tinplate closures?

- There are several different ways to recycle tinplate closures. One way is to separate the tinplate from other materials, such as plastic or glass, and then melt it down to create new tinplate products. Another method is to crush the closures into small pieces and use them as aggregate in construction materials like concrete. Tinplate closures can also be reprocessed and used in the production of new closures or other metal products. Additionally, recycling facilities may accept tinplate closures and send them to specialized recycling centers for further processing.

Send your message to us

Anti-Rust Aerosol Can For Spray, Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 PCS

- Supply Capability:

- 30000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords