Anping Wire Mesh factory for Stainless Steel Window Insect Screen

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Material: SUS/AISI 201 202 302 304 304HC 304L 316 316L etc.

Characteristic & Use: Excellent resistance against acid, alkali, heat and corrosion, extensively used in processing of oil, chemical, food, making wire mesh filter, also sorting and screening of solid, liquid and gas in mine, metallurgy, airspace and machine making etc.

More Information

1) product range : 30m ( up to 200m) long and in width of 36’ 48’ 1m 1.2m 1.5m 2.0m etc. or cut to length panels as per client’s requirement.

2) Weave: Plain Weave, Twill Weave ; Plain Dutch Weave, Dutch Twill Weave.

3) Mesh counts: 1 mesh to 635 mesh.

Quality: Meet Australia Market.

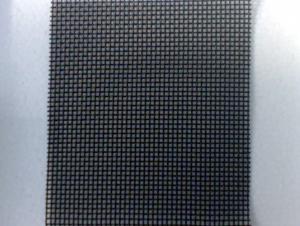

Mesh per inch: 11mesh x 11mesh

Wire Diameter: 0.8mm

Surface treatment: Black powder coated,Gray powder coated

Stainless steel security screens Property:

1. Equal tensile stainless steel wire,Equal wire diameter.

2. Equal hole size

3. Flat and straight surface

4. Meet australia standard,Pass knife test,Impact test,Jemmy attack test

1.6mm dia Stainless Steel Security Window Screen Mesh

Material:Stainless steel 304, 316, carbon steel.

Wire diameter and mesh size:

0.7mm x 12 mesh,

0.8mm x 11 mesh (Common specification),

0.9mm x 10 mesh,

1.0mm x 8.5 mesh,

1.6mm x 4 mesh.

Weaving method:Plain weave, crimp weave.

Surface: Electrostatic spray. The common colors are black, gray, white, yellow, etc.

1.Features:Acid resistant,Alkali resistivity,High-tempreture Resistance,Abrasion Resistant,Long Life,ect.

2.Application:It is widely used in these industries ,such as petroleum,chemical,chemical fiber,tyres manufacturing ,metallurgy,medicine,food.With its excellent resistance against acid,alkali and heat,find extensive uses in filtering , and sorting of solid ,liquid and gas

3.Stainless Steel Wire Mesh:can be divided into Stainless Steel Wire Mesh Square Opening and Stainless Steel Wire Mesh Dutch Weave according to weaving types, while Square Opening Stainless Steel Wire Mesh can be further divided into square wire mesh plain weave and square wire mesh twill weave.

FAQ

Advantages we have

A.Skilled and experienced workers

B.Perfect processing capabilities including shearing, sawing, punching, drilling, welding and additional fabrication

expertise

C.Better engineering, tighter tolerances, better prices, shorter lead times

D.Better value, quicker turnarounds, flexibility in options.

Benifits you get

A.Stable quality:Coming from good material,skilled workers and technique.

B.Lower Price:Not cheapest but the lowest at the same quality.

C.Good Service:Satisfactory service before and after sale.

D.Delivery Time:30-45 days for mass production

- Q: What is the effect of the wire mesh on the floor

- strong ground local load-bearing capacity: in the processing workshop, garage and other ground load larger room, to warm with wire mesh can improve the overall strength of the ground layer, to avoid ground cracking, collapse and so on.

- Q: Barbed wire mesh 20 mesh and 30 mesh what is the difference

- The mesh count refers to the number of holes of 2.54 cm. The unit used to express the mesh in the mesh product specification is hole / cm or line / cm. In countries and regions using imperial units of measurement, the mesh size is expressed in holes / inch or lines / inch.

- Q: This material of the barbed wire in the water I do not know how long?

- Fenqiang barbed wire is cold galvanized welded wire mesh, is the choice of high-quality low-carbon steel wire welded wire welded wire mesh, advanced welding process in each intersection are vertical and horizontal welding,

- Q: What is the mesh in the wire mesh specification?

- The smaller the mesh, the worse the ink passes, the larger the mesh, and the better the ink passes. In the selection of screen can be printed according to the accuracy requirements, select a different mesh mesh.

- Q: Construction in the wall and the beam at the junction of nail wire mesh what role

- To enhance the capacity of some of the ground, in the processing workshop, garage and other places on the ground load larger room, wire mesh can improve the overall structure of the ground layer strength, to avoid the ground cracking, fall and so on.

- Q: In the chemical experiment, how does the wire mesh use? What are the effects?

- Increase the contact area. So that the reaction of iron to participate more intense (fast)

- Q: How does the "jagged" on the back of the knife cut the barbed wire?

- Army knife sawtooth is mainly to eliminate the internal strength of the knife body, processing to be quenched, there are jagged, quenching time to eliminate the knife's internal stress, is more solid knife body, and in special times as a saw, do not have to cut wire mesh,

- Q: Is the warm tube laid on top of the steel wire or below?

- and that the road is broken, then the loop must be replaced by all the warm pipe, which means that your room layout of the road to warm all the area to all Out of all to replace the new pipe to replace.

- Q: How is the wire mesh made

- materials used generally use high-quality low-carbon steel or stainless steel. In general, it is necessary to produce a number of processes such as plate peeling, pickling, washing,

- Q: What is the use of wire

- If the rust does not remove, this sponge-like rust is particularly easy to absorb moisture, iron is rotten faster

Send your message to us

Anping Wire Mesh factory for Stainless Steel Window Insect Screen

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords