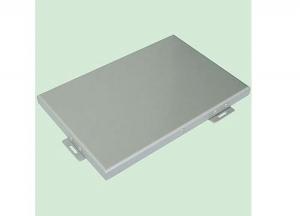

Aluminum Sandwich Wall Slat For Interior Wall Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

CMAX Aluminum Sandwich Wall Slat

CMAX® Integrated Sandwich Wall Panel is a brand new product which is gradually being applied on both indoor and outdoor wall decoration. It is a new product that can be seen as a substitute of paint. It is the panel that laminated with aluminum alloy panel, PU insulation layer and aluminum foil.

CMAX® Integrated Sandwich Wall Panel is famous for the good quality and reasonable price, also we provide customized service, you can provide us the picture that you want to print on the surface, we will do it accordingly.

CMAX® Integrated Sandwich Wall Panel is environment friendly product, which will be good replacement for wall paper and painting. and the fast installation and harmfull gas free will be the best to your home decoration and commerical site docoration. and it will show you a fantansitc effect.

Product Features:

Thermal insulation | Soundproof |

Fireproof (B2) | Hard enough |

Harmful gas free | Easy Installation |

Variety of surface design | Environmental friendly |

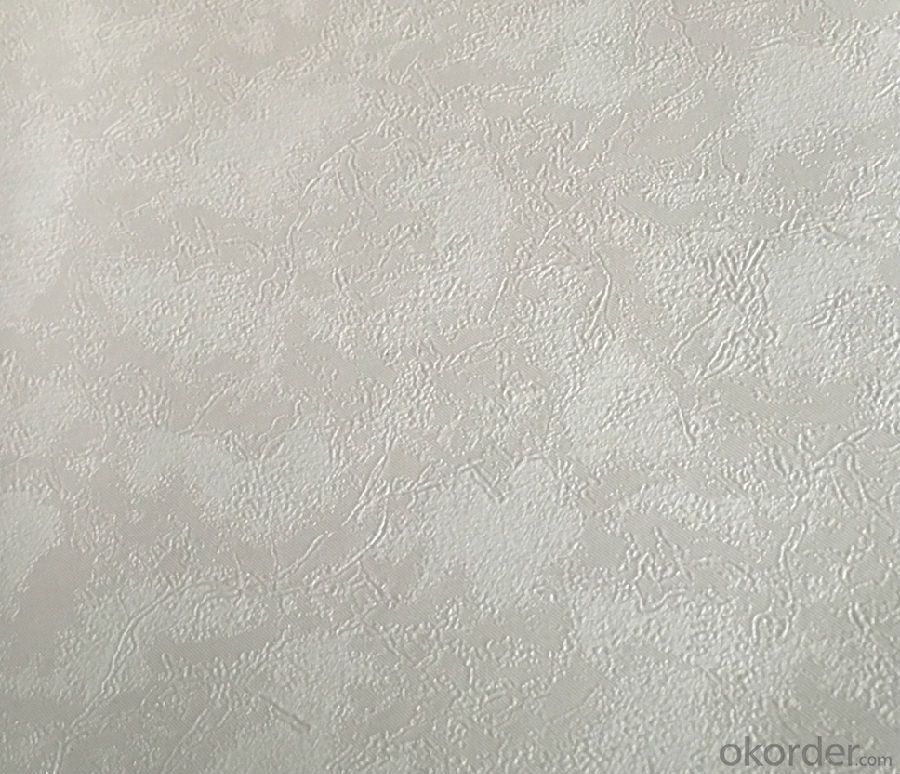

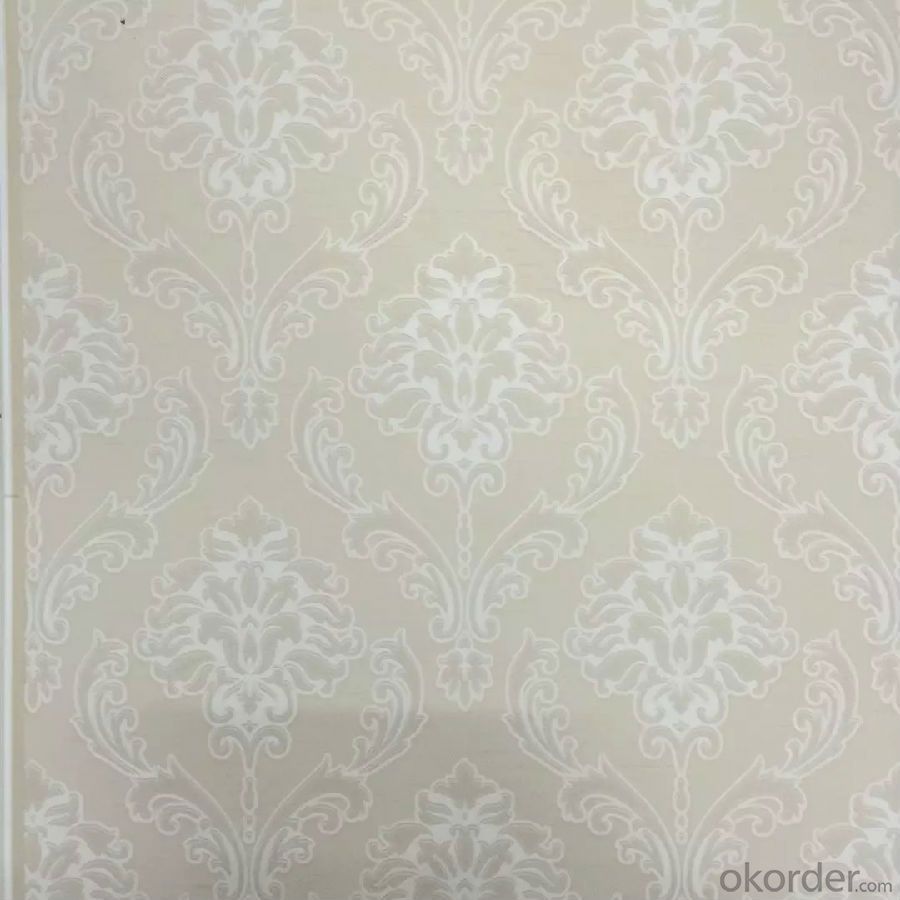

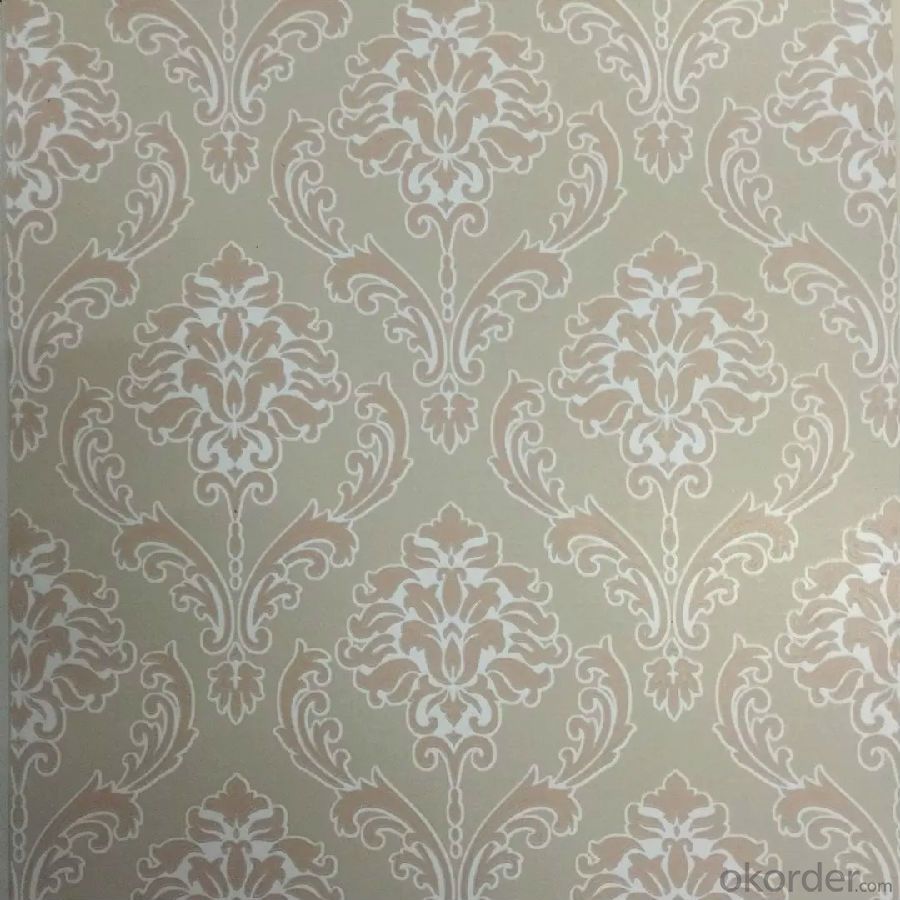

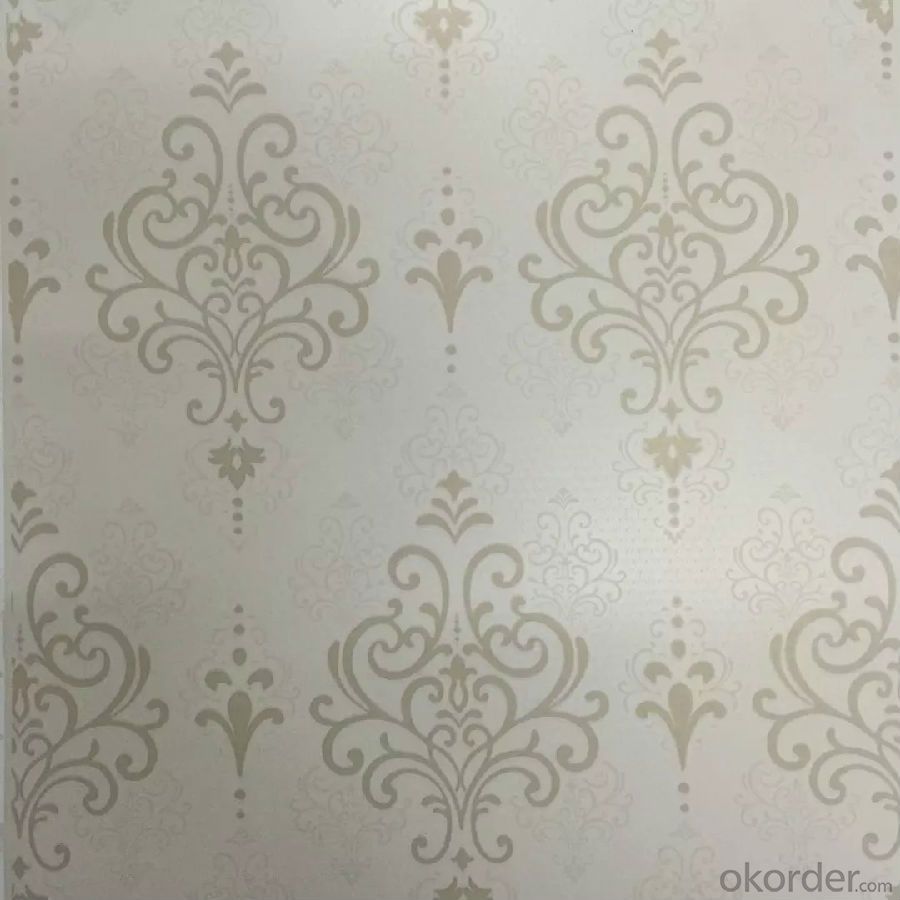

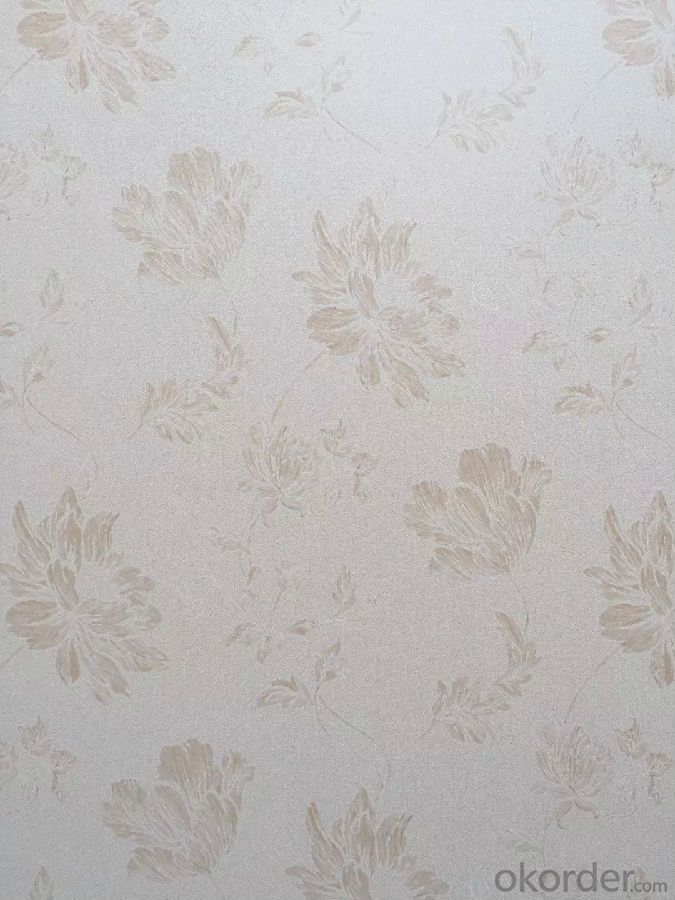

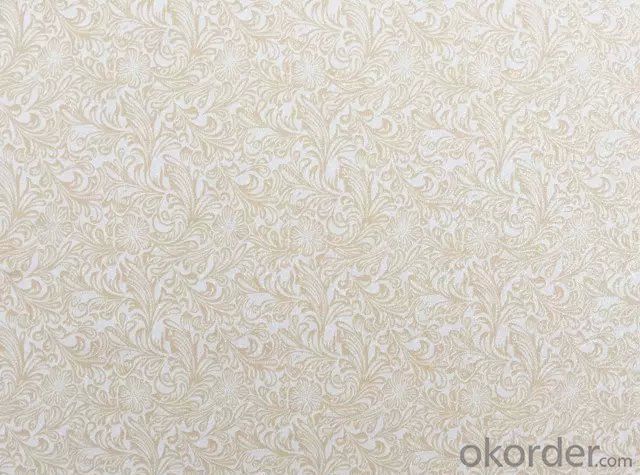

Samples Design of Surface:

Working Sketches:

- Q: Color steel sandwich panels are prefabricated or on-site production processing

- This is based on the specifications you want to color steel sandwich panels to customize, and some factories if you just need the specifications, then there may be spot Oh

- Q: Sandwich panel sandwich panel characteristics

- 1, the quality of light per square meter weight less than 24kg, can fully reduce the structural cost. 2, the installation of fast and light weight, plug, install and can cut the characteristics of arbitrary, to determine the installation of simple, can improve efficiency and save time. 3, fire, color steel composite plus core board of the surface material and insulation materials for non-burning or flame retardant materials, to meet the fire safety requirements. 4, fire-resistant, with a special coating of colored steel sheet up to 10-15 years, after every ten years spraying anti-corrosion coating, sheet life of 35 years 5, beautiful, pressure plate clear lines up to dozens of colors, with any style of the building needs 6, thermal insulation commonly used insulation materials are: rock wool, glass fiber cotton, polystyrene, polyurethane, low thermal conductivity, with a good thermal insulation effect. 7, environmental protection, noise, composite board noise intensity up to 40-50 dB, is a very effective sound insulation material. 8, plastic flexible steel plate can be arbitrarily cut, enough to meet the needs of special design. 9, high-strength high-strength steel plate as the substrate, tensile strength of 5600 (kg / cm2), coupled with the most advanced design and roll forming, with excellent structural characteristics

- Q: What is the acceptance criteria for rock wool sandwich panels?

- 1) upper and lower surface: the use of galvanized color steel plate, the thickness of 0.4-0.8mm. According to the specific requirements of customers, can also be used galvanized steel or galvanized steel plate. The steel plate is first molded by a molding machine and is compounded with the rock wool factory. ? 2) Yanmian core material: the use of density of 120kg / m yan rock block staggered laying, the fiber perpendicular to the sandwich plate on the upper and lower surfaces, and close contact to enrich the sandwich panel of the entire vertical and horizontal. The combination of rock wool and rock wool and the upper and lower steel plates through the high-strength foaming agent to form a whole, sophisticated production process to ensure that the high-density rockwool insulation and metal plate between the inner wall can produce poles Strong adhesion, so that the rock wool sandwich panel has a very good stiffness. ? Wujiang City Linxue purification Choi Board Co., Ltd. is the China Electronics Society Clean Technology Branch members. Commitment to various types of purification decoration, clean air-conditioning works, hydropower engineering facilities supporting the design, installation, commissioning through-train service.

- Q: Color plate and color steel sandwich panel difference?

- Color steel plate galvanized coated iron plate, the use of color steel plate is not insulated. Color steel sandwich panels are double-sided steel plate with the center of the core material through the machine continuous pressure from the type. The core material has foam, rock wool, polyurethane and extruded. The main feature is the insulation of insulation. hope this helps

- Q: Aluminum magnesium manganese composite sandwich panel 90 degrees right angle how to fold

- Certainly the aluminum magnesium manganese plate light, the proportion of aluminum magnesium manganese plate is 4.71, the proportion of color steel plate is 7.85.

- Q: What is the sandwich panel, sandwich board what is the use of what the characteristics of sandwich panels

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. Sandwich panels are a common product in the current building materials, not only good flame retardant and environmentally friendly Sandwich board English name: laminboard Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. [1] The formation of the outer steel plate takes full account of the structural and strength requirements, and take into account the aesthetic, the inner layer of the formation of flat to meet the needs.

- Q: Color board sandwich board and gypsum board partition which expensive

- Gypsum board to do with the wall quickly and free formaldehyde-free pollution If the use of positioning gypsum board can save 30%

- Q: Will the Yanmian sandwich color steel plate of the plant can reach the fire two grade requirements?

- Yanmian sandwich color of the core material is basalt and other natural ore as the main raw material, the high temperature melt into the fiber, adding the right amount of binder, curing and made. Is the same type (sandwich panel series) in the fire resistance of the strongest of a new type of fire board. Applicable to drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling, partition and so on. Fire time is 80 minutes. Some information on "with 600 ℃ fire resistance, fire rating to A level."

- Q: Sandwich board room is suitable for long-term residence

- Yes Sandwich board activities room life 10 - - 15 years or so (ground waterproof well

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

Send your message to us

Aluminum Sandwich Wall Slat For Interior Wall Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords