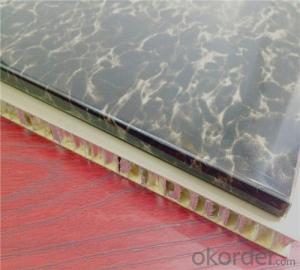

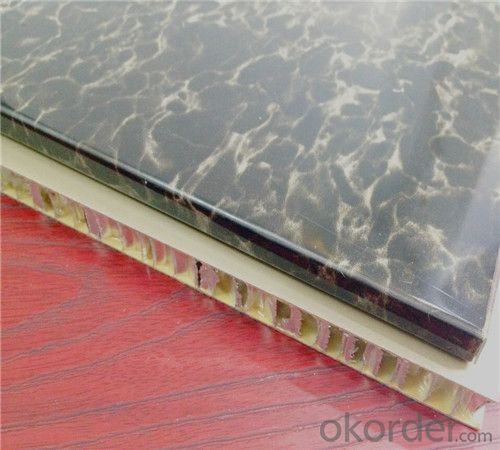

Aluminum sandwich panel / TOBOND wall panel

- Loading Port:

- Zhuhai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TOBOND PVDF ALUMINIUM COMPOSITE PANEL

TOBOND PVDF plus Aluminium Composite Panel is special metal surface wall cladding material, compounded with superior aluminum and LDPE Plastic.

Comparing to traditional metal panel, TOBOND ACP is with prime performance of economic efficiency, environment friendly and flexible installation.

Panel Size:1220*2440(mm)

TOBOND ACP Application

Outer wall cladding, curtain wall.

Redecoration of old buildings outer-wall.

Balconies, indoor partitions.

Units wall cladding

Advertisement signboard

Kitchen and bath room ceiling

Kitchen Cabinet surfacing decoration

Industrial Usage, Vehicle bodies.

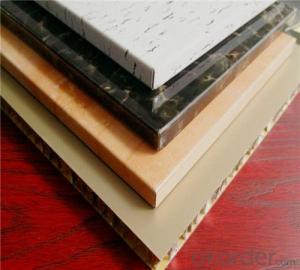

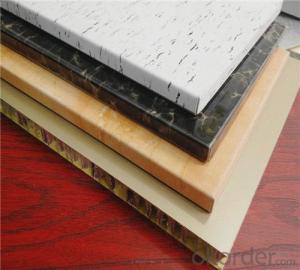

Color Chart:

STANDARD SIZE OF TOBOND ACP

Series | Coating | Usage | Panel Thickness | Panel Size(mm) |

PVDF Plus Outdoor Panel | PVDF | Exterior Wall Cladding | 4mm /3mm | 1220*2440 1220*2900 |

Indoor panel | Polyester | Interior Decoration/ Advertisement board | ||

Fireproof panel | PVDF/Polyester | Exterior Wall Cladding/Interior Decoration | ||

Special Size For Option | 6mm/5mm | 1250*2900 1500*2900 1500*5800 | ||

Proceeding Noticed

Storage: panel must be stored in cool dry place, and placed on flat surface.

Notching; if notching with notching equipment or gong equipment, using milling cutter with half round head≥90 degree. When notching, pls leave 0.2—0.3mm thickness plastic core materials bending with aluminium sheet to increase intension and tenacity, otherwise aluminium sheet may rupture or coating crack.

Arcing Machining: using professional bending equipment to machining, forcing inchmeal to make the panel reaching bending radian needed. Do not bending one-off.

Installation direction: panels must be install in same direction.

- Q: What are the chemical composition of aluminum veneer for building decoration

- JG / T 331-2017 Fluorocarbon aluminum veneer products for curtain walls (implemented on February 1, 2017)

- Q: Fire board 525 front line 38 thick, depth ≤ 600, aluminum plastic after the file water, FB-F09 edge of the price

- You did not understand, I did not understand.

- Q: What can aluminum-plastic plates do! Where to decorate! how to use!

- Aluminum-plastic composite board itself has a unique performance, determines its wide range of uses:

- Q: Curtain wall aluminum-plastic plate, Huatian and Huayuan brand how much difference? Including price.

- There is no obvious gap, according to our years of experience to judge, the difference will not exceed 5 yuan per square meter.

- Q: What is the difference between aluminum and aluminum?

- Aluminum plate, as the name suggests is made of aluminum or aluminum alloy material made of plate. Or by the flat aluminum embryo by heating, rolling and straightening or solid solution aging heat and other processes made of plate aluminum products.

- Q: Aluminum-plastic plate roof is similar to the shape of many store signs, but the area is much larger times, like a box of the same, the middle of the keel or something, the other few are aluminum-plastic panels, combined into a cube. The most intuitive understanding of the container, or sealed the top of the truck compartment, surrounded by closed but the middle of the gap, so although the indoor water leakage point is fixed, and perhaps can not explain that only these leaks leak, there may be other places leaking , Because some points are low or just the seams are so leaked from these points. From this point of view, I do not know whether the need to clean up all the previous waterproof ointment, all re-silica gel?

- You do not talk about how fast cracks, a total of how long, that is, if a tube of glass glue enough you can consider using (that is, sticky fish tank that kind of glue) and winter is not suitable for waterproof work, And thermal expansion and contraction are problematic. Another cost of plastic should also be considered.

- Q: What is the aluminum plate and fire board, what is the difference?

- Fire board is the paper immersed in the resin, after high temperature and high pressure treatment, the production of interior decoration surface materials. Fire board with wear, heat, impact resistance, acid and alkali, fire and other characteristics. Fire board can be used for table, desktop, wall, kitchen utensils, office furniture, door surface, hanging cabinet and other locations

- Q: Now sell a lot of aluminum-plastic plate, are OKorder auspicious aluminum-plastic plate, which is good?

- Yes ah, cloud like building materials is authentic

- Q: Ordinary decorative aluminum-plastic composite plate with the nominal thickness of aluminum is how much

- Common is 3mm / 4mm / 5mm / 6mm, the specific size of the two sides agreed to supply and demand. Deviation of about 0.2mm.

- Q: Aluminum-plastic plate universal flat-panel printer which is good, how much money?

- Aluminum-plastic plate universal printer is a kind of digital inkjet printer can print a lot of manufacturers concentrated in the coast, there are: Jintian, Han extension, and so on, manufacturers are more than one said, probably the price of tens of thousands to Twenty tens of thousands ranging from a penny goods, from the nozzle, configuration, after-sales service comparison.

Send your message to us

Aluminum sandwich panel / TOBOND wall panel

- Loading Port:

- Zhuhai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords