Aluminum PE Outdoor Roofing Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

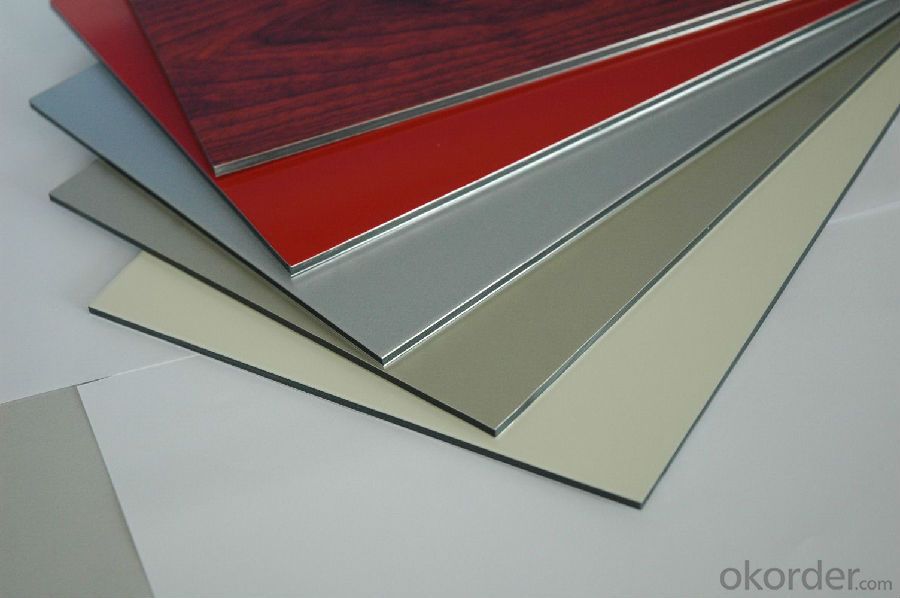

1. Structure of PE Aluminium Composite Panel for Outdoor Roofing Description

PE Aluminium Composite Panel for Outdoor Roofing is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of PE Aluminium Composite Panel for Outdoor Roofing

PE Aluminium Composite Panel for Outdoor Roofing | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of PE Aluminium Composite Panel for Outdoor Roofing

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of PE Aluminium Composite Panel for Outdoor Roofing

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of PE Aluminium Composite Panel for Outdoor Roofing

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

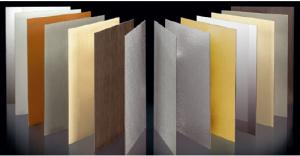

6. Image of PE Aluminium Composite Panel for Outdoor Roofing

7. Package and shipping of PE Aluminium Composite Panel for Outdoor Roofing

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to recycle aluminum using renewable energy sources such as solar or wind power?

- <p>Yes, aluminum can be recycled using solar energy or wind energy. The recycling process involves melting the aluminum, which can be powered by electricity generated from renewable sources. Solar panels and wind turbines can produce the electricity needed for this process, reducing the carbon footprint associated with aluminum recycling. In fact, recycling aluminum requires only 5% of the energy needed to produce new aluminum from raw materials, making it an energy-efficient process that benefits significantly from renewable energy sources.</p>

- Q: This question asks for typical applications of aluminum foil in everyday life.

- <p>Aluminum foil is commonly used for food storage and preservation, as it can be wrapped around food to keep it fresh. It's also widely used in cooking, particularly for baking and roasting, to prevent food from sticking to pans or to seal in moisture and flavor. Beyond culinary uses, aluminum foil is employed in arts and crafts for creating 3D structures or as a reflective surface. It's also used in insulation, as a barrier in construction, and for packing and wrapping items to protect them during shipping. Additionally, aluminum foil is utilized in various industrial processes due to its heat resistance and malleability.</p>

- Q: Is it possible to utilize aluminum to enhance the durability and efficiency of batteries?

- <p>Yes, aluminum can be used to make batteries more durable and efficient. Aluminum's lightweight, high conductivity, and corrosion resistance make it a favorable material for battery components. In particular, aluminum-air batteries leverage aluminum's ability to provide a high energy density. Additionally, research is ongoing to improve lithium-ion batteries by using aluminum as a component in the anode, which can potentially increase energy storage capacity and lifespan. However, challenges such as aluminum's reactivity and the development of efficient recycling methods must be addressed for widespread adoption in battery technology.</p>

- Q: Explain the distinction between pure aluminum and aluminum alloys, focusing on their composition and properties.

- <p>Pure aluminum is composed of aluminum alone, with a high degree of purity, typically over 99%. It is soft, malleable, and has good thermal and electrical conductivity. Aluminum alloys, on the other hand, are made by combining aluminum with other elements such as copper, magnesium, or silicon to enhance their strength, durability, and resistance to corrosion. These alloys are harder than pure aluminum and can be tailored for specific applications, making them more versatile for industrial use.</p>

- Q: Explain how the inclusion of copper impacts the characteristics of aluminum alloys.

- <p>The addition of copper to aluminum alloys significantly enhances their strength and hardness. Copper is one of the most effective alloying elements for aluminum, leading to the formation of a series of age-hardenable alloys known as the 2xxx series. These alloys, such as 2024, are characterized by their high strength-to-weight ratio and are often used in aerospace applications, structural components, and transportation equipment. The copper atoms in the aluminum matrix form precipitates that strengthen the alloy through a process called precipitation hardening. However, the addition of copper also reduces the alloy's ductility and corrosion resistance, necessitating careful control of the copper content and heat treatment processes to optimize the alloy's properties for specific applications.</p>

- Q: This question asks for common uses of aluminum in everyday life.

- <p>Aluminum is widely used in daily life due to its lightweight, corrosion resistance, and affordability. Some applications include: 1) Food and beverage cans for preserving food and drinks. 2) Aluminum foil used for cooking and food storage. 3) Construction materials, such as window frames and roofing. 4) In transportation, like car parts and airplane components to reduce weight. 5) Electrical wiring due to its high conductivity. 6) Household items like pots and pans, and furniture. 7) Packaging materials for various products. 8) In sports equipment like bicycle frames and tennis rackets. These applications highlight aluminum's versatility and importance in everyday life.</p>

- Q: Are aluminum alloys suitable for use in the aerospace industry?

- <p>Yes, aluminum alloys are extensively used in aerospace applications due to their high strength-to-weight ratio, corrosion resistance, and good fatigue characteristics. They are particularly favored for constructing airframes, wings, and other structural components where weight savings are critical. The alloys are also used in manufacturing engine parts and heat exchangers due to their thermal conductivity and ability to withstand high temperatures. However, the specific alloy selection depends on the particular requirements of the application, such as temperature resistance, strength, and environmental conditions.</p>

- Q: Is it safe and common to use aluminum in food packaging?

- <p>Yes, aluminum is commonly used in food packaging due to its lightweight, durability, and excellent barrier properties against light, oxygen, and moisture. It is often used in the form of aluminum foil and aluminum-coated films or laminates to protect food and extend its shelf life. However, there are concerns about the potential health risks of aluminum exposure, and it's important to note that regulations and guidelines exist to ensure that aluminum levels in food packaging are safe for consumers.</p>

- Q: This question asks for examples of alloys that include aluminum as one of their components.

- <p>Aluminum is a versatile metal that forms many alloys, enhancing properties like strength, corrosion resistance, and electrical conductivity. Some common aluminum alloys include: 1. 6061, used in aircraft structures and automotive parts due to its good mechanical properties and machinability. 2. 2024, known as 'Alclad', is strong and used in aircraft structures. 3. 7075, one of the strongest aluminum alloys, used in aerospace and military applications. 4. 3003, used for cooking utensils and chemical equipment due to its good corrosion resistance. 5. 5052, used in marine applications and food processing equipment for its excellent corrosion resistance. These alloys are widely used in various industries due to their unique properties.</p>

- Q: This question inquires about the potential differences in cooking performance when using various types of aluminum foil.

- <p>Yes, there are differences in cooking performance between different types of aluminum foil. The thickness of the foil can affect heat distribution and cooking time; heavier gauges are more durable and better for roasting and baking, while thinner foils are suitable for lining pans or wrapping foods. The quality of the foil, such as whether it's non-stick or not, can impact food release and cleanup. Additionally, some aluminum foils are designed to be heat resistant up to higher temperatures, making them suitable for broiling or grilling, while others may not withstand such high heat. It's important to use the appropriate type of aluminum foil for the specific cooking method to ensure food safety and optimal results.</p>

Send your message to us

Aluminum PE Outdoor Roofing Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords