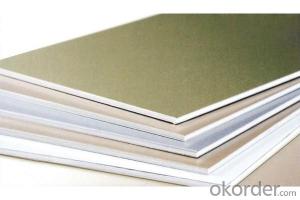

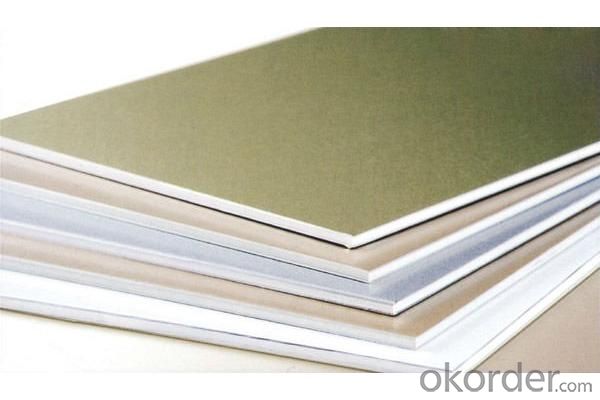

PE PVDF aluminium composite panel exterior cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PE PVDF aluminium composite panel exterior cladding

| PRODUCT PARAMETER | |||||

| Product name | Pvdf Aluminum Composite Panel | ||||

| Material | Aluminum sheet and PE | ||||

| Brand name | Kaysdy | ||||

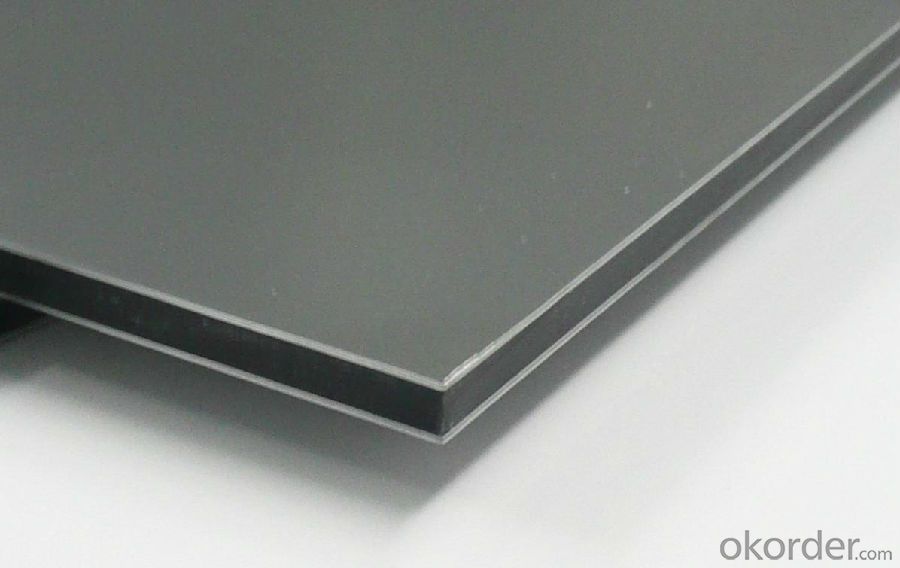

| Standard size | 1220mm x 2440mm x 3mm, 1220mm x 2440mm x 4mm | ||||

| Optional size | panel thickness | 3mm - 5.8mm | |||

| aluminum skin thickness | 0.08mm, 0.10mm, 0.12mm, 0.15mm, 0.18mm, 0.21mm, 0.25mm, 0.30mm, 0.35mm, 0.40mm, 0.45mm, 0.50mm | ||||

| panel width | 0.9m - 1.57m | ||||

| 0.9m - 1.57m | |||||

| panel Length | 5.8m is the best choice for container, or according to customized | ||||

| Core layer | Common PE or fireproof PE | ||||

| Surface coating | Polyester(PE) or Fluorocarbon(PVDF) | ||||

| Special treatment | Brushed, mirror, marble pattern, etc | ||||

| Features | 1. Excellent weather resistance | ||||

| 2. Outstanding characteristics of fireproof | |||||

| 3. High peel strength | |||||

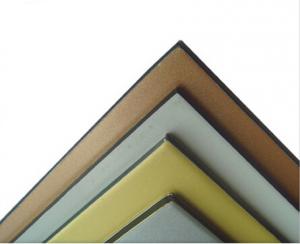

| 4. Multiple colors | |||||

| 5. Easy and rapid installation | |||||

| 6. Environment friendly and Recycle | |||||

| 7. Perfect rigidity | |||||

| 8. Cleanness Maintenance | |||||

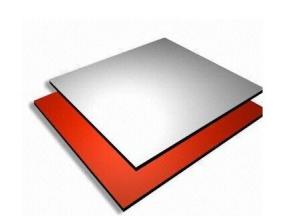

Pvdf Aluminum Composite Panel Material

a) Front:Aluminum-alloy sheet coated with fluoro-carbon resin (PVDF) and polyester resin (PE) roasting painting;

b) Core:nontoxic polyethylene;

c) Back:Aluminum-alloy sheet coated with polyester resin painting;

d) Surface finish:Treated with PVDF and PE resin rolling roasting coating;

e) Aluminum alloy sheet thickness: 0.04~0.5mm.

Aluminum Composite Panel Characteristics

Super peeling strength;

Excellent surface flatness and smoothness;

Superior weather, corrosion and pollutant resistance;

Even coating, various colors;

Fireproof, excellent heat and sound insulation;

Superior impact resistance;

Lightweight and easy to process;

Easy to maintain.

- Q: Where is the sale of aluminum-plastic color steel composite panels (panel is 0.5mm thick blue steel plate is a foam or rock wool floor is aluminum-plastic plate)

- You say it is aluminum! If the aluminum plate is heard, but the aluminum plate can not heard of!

- Q: Answer: drawing wire and aluminum plate internal structure Thank you

- Surface drawing, the use of fire core material of the aluminum plate

- Q: Can aluminum panels be used for home improvement? Want to be decorated as a wall!

- Aluminum-plastic panels can be used for interior furnishings.

- Q: China aluminum-plastic plate door decoration materials, where to buy a good point? Have prawn help?

- To Kunming cloud like building materials to buy, they are a set of aluminum-plastic plate, aluminum veneer production and wholesale as one of the large curtain wall decoration materials business, the introduction of the quality of aluminum-plastic plate is very good.

- Q: Aluminum plate thickness for outdoor and indoor is not the same?

- Indoor use: generally 3MM polyester coating. The thickness of the aluminum skin is 12 wire, 15 wire, 18 wire, 21 wire, 25 wire, 30 wire, etc .; but there are more thin, 8 wire, 6 wire and so on.

- Q: Aluminum-plastic plate and color steel tile which is more durable

- Aluminum-plastic panels are more durable.

- Q: Reflective film mounted to the aluminum-plastic plate, just mounted on a very flat, a night arch on why

- Bubble or arched, it is because the inside into the air caused .I think there is no other reason.

- Q: How to judge the market now on the advantages and disadvantages of aluminum-plastic composite panels

- Whether it can easily tear the aluminum down, inside the board can not point

- Q: Home decoration, please curtain wall with aluminum plate how much the price per flat

- According to my knowledge, I say ~ aluminum-plastic composite board is a chemically treated aluminum plate for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials The The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Aluminum-plastic composite panels in the country has been widely used, belonging to a new type of building decoration materials. I know that the general price is between 80 to 120 yuan This is what I know the information, I hope you have a reference role ~

- Q: OKorder where to buy aluminum panels, aluminum veneer, aluminum honeycomb panels sun panels, artificial stone countertops, translucent slate, Shu Le homes

- OKorder nobody doing aluminum honeycomb board to do these most famous is Foshan, Guangdong you can ask me

Send your message to us

PE PVDF aluminium composite panel exterior cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords