Standard Grade Paper Packaging Tape with Aluminum Foil Synthetic Rubber Based Silver Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

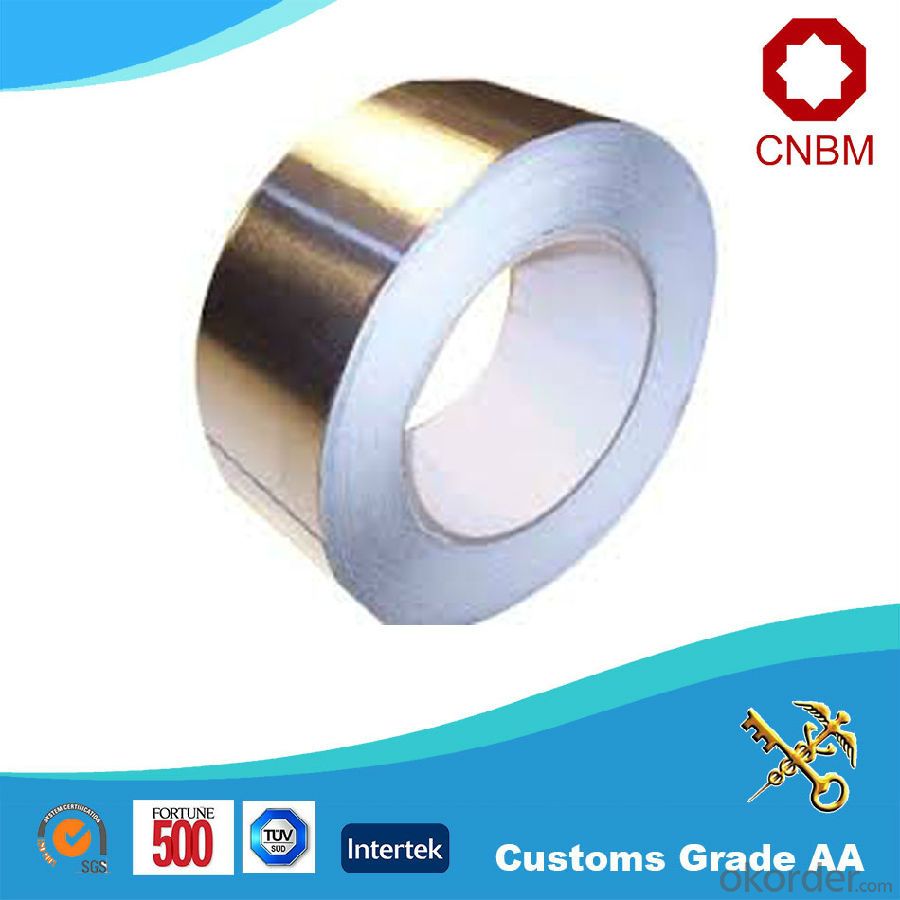

Aluminum Foil Tape Synthetic Rubber Based Silver Color

1. Structure of Aluminum Foil Tape Description

Aluminum Foil Tape is of aluminum foil as the carrier, coating with solvent based acrylic, synthetic rubber-resin, or water based acrylic adhesive. General purpose of Synthetic Rubber Based Aluminum Foil Tape: widely used for seaming and jointing bonding of various vapor barriers, fixing thermal fin in refrigerators. Provide fast and permanent bond performance for vapor barrier against the moisture.

2. Main Features of Aluminum Foil Tape

Excellent in adhesion and flame retardant

Resistance to cold, heat and aging.

High Temperature stability

High mechanical strength and good impact resistance

3. Aluminum Foil Tape Images

4. Aluminum Foil Tape Specification

Item | Aluminum Foil Tape |

Adhesive | hot melt/ water based acrylic |

Thickness (micron) | 35 |

Initial Tack (14# mm) | 18 |

Adhesion to Steel (N/25mm) | 40 |

Service Temperature (℃) | 60 |

Holding Power (h) | Rolls in Carton |

Packing | Rolls in Carton |

Certification | SGS and ISO9001 |

5. FAQ

Q1. What is the specification of Aluminum Foil Tape?

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1200mm; length according to customers’ requirements

Q2. What kind of service we can provide for you?

Sample of Aluminum Foil Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. What is our company?

CNBM International Corporation is a state-owned company. As World Top 500 Company, we have clients from over 120 countries and overseas branches in 5 countries. We specialized in adhesive tape for over 20 years, with SGS and ISO9001 certified and Grade AA for Export.

- Q: Can packaging tape be used for labeling?

- Yes, packaging tape can be used for labeling. While packaging tape is primarily used for sealing packages and boxes, it can also serve as a convenient way to label items. By writing directly on the tape or attaching a paper label to it, you can easily identify the contents of a package or mark it for specific purposes. However, it is important to note that using packaging tape for labeling may not be as durable or long-lasting as using dedicated label materials. Additionally, the adhesive on packaging tape may not be as strong as that on specialized labels, which could lead to labels falling off or becoming less visible over time. Therefore, while packaging tape can be used for labeling in some cases, it may be more suitable for short-term or temporary labeling needs.

- Q: Is packaging tape transparent?

- Indeed, transparency can be found in packaging tape. Various forms of packaging tape are manufactured using clear substances like polypropylene or acrylic, which enable them to possess a see-through quality. The advantage of this transparency lies in its ability to allow users to effortlessly view the contents of a package without the need for unwrapping. Furthermore, transparent packaging tape is often favored in situations where a polished and professional appearance is desired, as it effortlessly blends with diverse packaging materials. Nonetheless, it is worth mentioning that not all packaging tapes possess transparency, as there are also options available in colored or printed variations that cater to specific purposes or branding requirements.

- Q: Can packaging tape be used for sealing packages with delicate fabrics or clothing?

- Yes, packaging tape can be used for sealing packages with delicate fabrics or clothing. However, extra care should be taken to prevent any damage to the fabric. It is recommended to use a gentle touch while sealing the package and consider adding an additional layer of protective material, such as tissue paper or bubble wrap, to provide cushioning and prevent any potential damage.

- Q: Is packaging tape compatible with automatic packaging machines?

- Yes, packaging tape is compatible with automatic packaging machines. Automatic packaging machines are designed to work with a variety of packaging materials, including packaging tape. They are equipped with mechanisms to efficiently dispense and apply packaging tape to seal packages.

- Q: Can packaging tape be used for sealing plastic bottles?

- Indeed, the utilization of packaging tape in sealing plastic bottles is possible. Designed with the purpose of providing a secure and tight seal on various surfaces, including plastic, packaging tape boasts robust adhesion. Consequently, it effectively ensures the security and protection of the bottle's contents. Nevertheless, it is crucial to acknowledge that packaging tape may not match the efficacy of specialized bottle sealing alternatives like bottle caps or seals. These alternatives are exclusively crafted for plastic bottles and offer a more dependable and leak-proof seal. Consequently, although packaging tape can serve as a temporary solution, it is advisable to employ proper bottle sealing options for the long-term storage or transportation of liquids.

- Q: Can packaging tape be used for sealing office supplies or stationery?

- Yes, packaging tape can certainly be used for sealing office supplies or stationery. It is a versatile adhesive tape that is commonly used for sealing boxes and packages. However, when using packaging tape for sealing smaller items like office supplies or stationery, it is important to consider the size and weight of the item. If the item is lightweight and the packaging tape is not too wide or bulky, it can be a convenient and effective option for sealing. However, for smaller items, it may be more suitable to use other types of tape, such as clear tape or double-sided tape, which are specifically designed for sealing stationery and office supplies.

- Q: Is packaging tape safe for use on painted surfaces or walls?

- Packaging tape is generally not recommended for use on painted surfaces or walls, as it can potentially damage the paint when removed. It is advisable to use painter's tape or other specialized tapes specifically designed for use on painted surfaces to avoid any harm or residue.

- Q: Can packaging tape be used for sealing packages with automotive parts or accessories?

- Yes, packaging tape can be used for sealing packages with automotive parts or accessories. Packaging tape is designed to securely seal packages, and it can effectively hold together packages containing automotive parts or accessories. It provides a strong adhesive bond, ensuring that the package remains sealed during transportation or storage. Additionally, packaging tape is often resistant to moisture, which is important when shipping automotive parts or accessories that may be sensitive to water damage.

- Q: Can packaging tape be used for sealing glass or delicate items?

- Yes, packaging tape can be used for sealing glass or delicate items. However, it is important to handle the items with care and apply the tape gently to avoid any damage. It is recommended to use a cushioning material like bubble wrap or foam to provide additional protection before sealing with packaging tape.

- Q: Can packaging tape be used for sealing envelopes?

- Yes, packaging tape can be used for sealing envelopes. It provides a strong and secure seal that helps protect the contents of the envelope.

Send your message to us

Standard Grade Paper Packaging Tape with Aluminum Foil Synthetic Rubber Based Silver Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords