Aluminum Foil Facing Double Side 2-Way Scrim Reinforced Insulation Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Foil Facing Description:

Aluminium Foil Facing Insulation provides excellent insulation: reflects up to 97% of radiant energy in addition to resisting other types of heat transfer from conduction,convection,and radiation.The side of metalized PET/Alu forms an effective barrier against moisture,air currents and vapors.It is economical solution in many field. It is a light duty, Eco grade D/S foil Insulation. It is ideally used as sarking and insulation under roofs , in walls behind cladding or under timber floors , for residential and commercial building. Combining with glasswool or foam insulation, it is excellent as a vapor barrier for air-conditioning ducts, pipes and vessels.

2.Main Features of the Aluminium Foil Facing Insulation:

High heat reflection & low thermal conductivity

Heat preservation & energy saving

Moisture barrier & waterproof

Low flammability

Strong, durable & corrosion resistance

Light weight & easy to install

Clean, safe and fibre free & no odour and toxicity, totally environmental-friendly

No mildew growth & no rodent and insect nesting

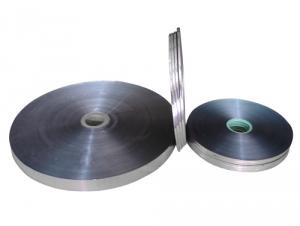

3. Aluminium Foil Facing Insulation Images

4. Aluminium Foil Facing Insulation Specification

Appearance : silver

Structure : aluminum foil/polyethylene/2-way scrim/kraft paper/ polyethylene / aluminum foil

Width : 120/125/130cm

Length : 100/200m

Norm : 112g/m2

Tensile strength: Endwise: 135N/25mm

Broadwise: 131N/25mm

Bursting strength: 124N

Temperature resistance: 4 hours no decladding -40°C/90°C

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe

,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: This question asks for the proper method of using aluminum foil to wrap food, with emphasis on the correct side of the foil facing outward.

- <p>To wrap food correctly with aluminum foil, you should use the dull side of the foil facing outward, which is in contact with the food. The shiny side has a non-stick surface and is not recommended for direct food contact as it may contain substances that could potentially leach into the food when heated. Start by cutting a piece of foil large enough to fully cover the food. Place the food in the center, then fold the foil over, crimping the edges to seal tightly. This will help retain moisture and heat, and prevent any potential cross-contamination.</p>

- Q: What precautions should be taken when handling hot food using aluminum foil as a cooking tool?

- <p>When handling hot food using aluminum foil, first ensure the foil is thick enough to withstand high temperatures without puncturing. Always use heat-resistant gloves or a thick cloth to avoid burns. Do not wrap food directly in aluminum foil if it's very hot, as this can cause the foil to tear or the food to stick. Allow the food to cool slightly before wrapping. When removing the foil from the heat source, use tongs or a spatula to avoid direct contact with the hot foil. Be cautious of steam when opening the foil, as it can be very hot.</p>

- Q: Is it safe and practical to use aluminum foil facing as a substitute for a kitchen cutting board?

- <p>Using aluminum foil facing as a kitchen cutting board is not recommended. While it may seem like a convenient alternative, it can dull your knives quickly and may not be as sanitary as a proper cutting board. Aluminum foil is also not designed to withstand the pressure and friction of cutting, which could lead to tearing or puncturing the foil, potentially causing injury or contamination. It's best to use a cutting board made from materials like wood, plastic, or bamboo, which are specifically designed for food preparation and cutting.</p>

- Q: This question asks about the optimal methods for placing food in a microwave using aluminum foil, specifically focusing on the orientation of the foil's facing.

- <p>The best way to store food in a microwave using aluminum foil is to avoid using it altogether. Aluminum foil is not recommended for use in microwaves because it can cause sparks and potentially start a fire. Instead, use microwave-safe containers made of glass, ceramic, or plastic. If you must use aluminum foil, ensure it does not touch the microwave's walls or ceiling and that it is not in direct contact with the food. However, for safety and efficiency, it's best to use appropriate microwave-safe materials.</p>

- Q: Explain the distinctions between aluminum foil facing and tin foil, including their composition and uses.

- <p>Aluminum foil facing and tin foil are both thin sheets of metal used for various purposes, but they differ in composition and properties. Aluminum foil facing is a thin layer of aluminum bonded to a substrate, often used in construction for insulation, while tin foil is pure tin and is used for wrapping food or as a decorative element. Aluminum foil is lightweight, corrosion-resistant, and conducts heat well, making it ideal for cooking and insulation. Tin foil, on the other hand, is less common in everyday use due to its higher cost and lower durability compared to aluminum. It is often used in niche applications such as art and craft projects or for certain types of food packaging that require a barrier to light and oxygen.</p>

- Q: Explain how to best utilize aluminum foil facing in the preparation of a sandwich.

- <p>The best ways to use aluminum foil facing in a sandwich include: 1) Wrapping the sandwich to keep it fresh and prevent it from drying out, especially when storing for later. 2) Using it as a makeshift 'grill' by placing the sandwich between two sheets of foil and toasting it in a panini press or on a stovetop for a crispy exterior. 3) Creating a foil pouch by sealing the sandwich in foil, which can be used for cooking sandwiches in an oven or on a campfire, keeping the ingredients moist and tender. 4) Using foil to press down on the sandwich while grilling or toasting, ensuring even heat distribution and a uniform texture. Always ensure the foil is food-safe and does not come into direct contact with the sandwich's fillings to avoid any potential contamination.</p>

- Q: What are the most suitable materials for creating aluminum foil facing?

- <p>The best materials for making aluminum foil facing are typically aluminum alloys, specifically 1100, 3003, or 8011 series alloys. These alloys offer excellent formability, corrosion resistance, and reflectivity, which are crucial for applications like insulation, construction, and heat management. Additionally, the facing material often includes a layer of polyester or polyethylene film to enhance durability and prevent tearing. The choice of material can also depend on specific requirements such as temperature resistance, UV resistance, and environmental conditions.</p>

- Q: This question asks for a list of various types of aluminum foil facing that can be found in the market.

- <p>There are several types of aluminum foil facing available in the market today, including: 1. Standard Aluminum Foil Facing, which is the most common type used for insulation and moisture protection. 2. Reinforced Aluminum Foil Facing, which is stronger and more durable, often used in high-temperature applications. 3. Embossed Aluminum Foil Facing, which has a textured surface for improved aesthetics and grip. 4. Coated Aluminum Foil Facing, which is coated with materials like polyethylene for added protection against chemicals or moisture. 5. Perforated Aluminum Foil Facing, which has small holes for ventilation or drainage. 6. Laminated Aluminum Foil Facing, which combines aluminum with other materials for enhanced properties. These types cater to various applications in construction, food packaging, and other industries.</p>

- Q: Is it safe to use old aluminum foil for food packaging, considering potential health risks and material degradation?

- <p>Using old aluminum foil for food packaging is not recommended. Over time, aluminum foil can become discolored, thin, or develop pinholes, which can compromise its integrity. These changes can lead to food contamination and the foil's ability to protect food from bacteria or other contaminants. Additionally, old aluminum foil may contain residues from previous uses that could mix with new food items, potentially causing off-flavors or health concerns. It's best to use fresh, clean aluminum foil for food packaging to ensure safety and hygiene.</p>

- Q: The user is inquiring whether it is safe and practical to use plastic containers for the purpose of freezing food.

- <p>Yes, you can use plastic containers for freezing food, but it's important to choose the right type. Opt for containers labeled as microwave-safe, freezer-safe, or BPA-free. Avoid using containers that become brittle or warp at low temperatures as they may crack or leak. Always leave a little space in the container for expansion to prevent breakage. It's also recommended to transfer frozen food to airtight containers or glass for longer-term storage to maintain food quality and safety.</p>

Send your message to us

Aluminum Foil Facing Double Side 2-Way Scrim Reinforced Insulation Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords