Aluminum Foil Facing Aluminium Foil Mylar for Cable and Flexible Ducts Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 31 lb/ft

- Supply Capability:

- 1231321 lb/ft/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

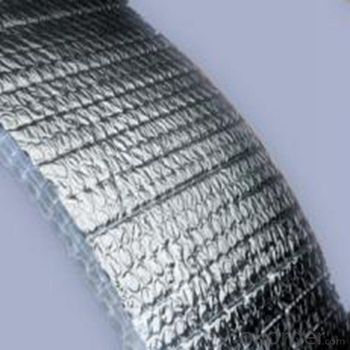

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

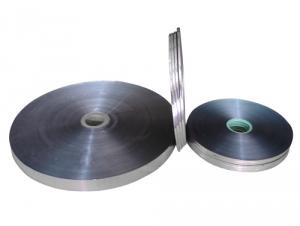

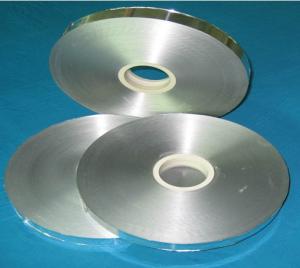

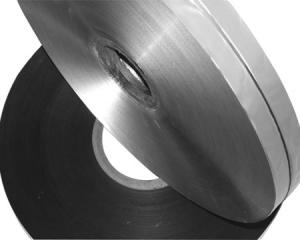

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is it possible to use aluminum foil with a reflective side to wrap sandwiches?

- <p>Yes, you can use aluminum foil facing to make sandwiches. The reflective side of aluminum foil is food-safe and can be used to wrap sandwiches for storage or transportation. It helps to keep the sandwich fresh and prevents it from drying out. However, it's important to ensure the foil is clean and free from any sharp edges that might tear the bread or packaging. Additionally, it's best to avoid using foil with non-stick coatings on the inside when in contact with food.</p>

- Q: The user is asking if it's possible to use aluminum foil with a reflective side to cook a pot roast.

- <p>Yes, you can use aluminum foil with a reflective side to make a pot roast. Aluminum foil is a versatile tool in cooking and can be used to wrap the roast, helping to retain moisture and cook the meat evenly. Ensure the foil is heavy-duty to withstand the cooking process and avoid punctures. Remember to monitor the roast closely to prevent overcooking, and adjust cooking times and temperatures as needed.</p>

- Q: What are some safer alternatives to aluminum for food packaging?

- <p>Yes, there are several alternative materials for food packaging that are considered safer than aluminum. These include biodegradable materials like PLA (polylactic acid), which is derived from renewable resources like corn starch. Paper-based packaging is also a popular choice, often coated with wax or other materials for added protection. Additionally, glass containers are a non-toxic and reusable option. Some companies are exploring innovative solutions like mushroom-based packaging and edible packaging made from seaweed. These alternatives aim to reduce environmental impact while maintaining food safety and quality.</p>

- Q: Is it safe and practical to reuse plastic food wrap materials after cleaning them?

- <p>Reusing food wrap materials after washing them is generally not recommended. Plastic wraps can lose their effectiveness as barriers against bacteria and air after one use. Washing them can also introduce bacteria and may not fully remove any residual food particles. For food safety and hygiene, it's better to use new, clean wraps each time.</p>

- Q: Can the shiny side of aluminum foil be utilized as a reflective surface?

- <p>Yes, aluminum foil facing can be used as a reflector. Aluminum foil has a highly reflective surface, which makes it suitable for reflecting light and heat. The shiny side of the foil is particularly effective due to its smooth and polished finish. It is commonly used in various applications such as cooking, gardening, and DIY projects to reflect heat or light. However, it's not as efficient as specialized reflective materials like mirrors or aluminum-coated fabrics, and it can degrade over time with exposure to elements.</p>

- Q: What are the eco-friendly options available to replace plastic containers?

- <p>Yes, there are several alternatives to plastic containers that are more environmentally friendly. Glass containers are a popular choice due to their durability and ability to be reused multiple times. Stainless steel containers are also a great option as they are long-lasting and do not leach chemicals. Biodegradable materials like bamboo, silicone, and certain types of plant-based plastics are other alternatives. Additionally, using cloth bags or reusable food wraps can help reduce the need for single-use plastic containers.</p>

- Q: Is it possible to use aluminum foil facing as a material for creating a potpourri sachet?

- <p>Yes, you can use aluminum foil facing to make a potpourri sachet. Aluminum foil is a versatile material that can be cut into small squares or shapes and filled with dried flowers, herbs, and spices to create a fragrant sachet. Ensure the foil is clean and free from any oils or residues before use. Seal the edges of the foil to prevent the contents from spilling out. While it's not as breathable as fabric, it can still hold the scent and keep the potpourri fresh.</p>

- Q: Is there a risk associated with using aluminum foil with raw meat or fish?

- <p>Yes, it is generally safe to use aluminum foil when handling raw meat or fish, as long as it is food-grade aluminum foil. Aluminum foil is designed to be non-toxic and resistant to corrosion, making it suitable for cooking and food preparation. However, it's important to ensure that the foil does not tear or puncture, as this could allow bacteria to contaminate the food. Additionally, avoid using aluminum foil in direct contact with acidic foods, as this can cause the foil to corrode and potentially release aluminum into the food. Always follow proper food safety guidelines when preparing and cooking with raw meats and fish.</p>

- Q: Is there a concern that aluminum from aluminum foil can seep into food during cooking or storage?

- <p>There is minimal risk of aluminum leaching from aluminum foil into food. Aluminum foil is generally safe for cooking and food storage when used properly. The risk increases with acidic or alkaline foods and high temperatures, but under normal cooking conditions, the amount of aluminum that could leach is negligible. However, it's best to avoid wrapping food in aluminum foil for long periods or at very high temperatures to minimize any potential exposure.</p>

- Q: How to properly handle aluminum foil when it is exposed to hot or cold temperatures.

- <p>When handling aluminum foil that is hot or cold, it's best to use tongs, a fork, or a pair of gloves to avoid direct skin contact. This prevents burns from hot foil or frostbite from cold foil. If the foil is being used in cooking, ensure it's not in direct contact with the heat source for prolonged periods to prevent melting. For cold applications, like insulation, make sure the foil is dry to maintain its effectiveness as a barrier. Always handle with care to prevent tearing or puncturing the foil, which could compromise its integrity.</p>

Send your message to us

Aluminum Foil Facing Aluminium Foil Mylar for Cable and Flexible Ducts Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 31 lb/ft

- Supply Capability:

- 1231321 lb/ft/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords