Aluminum Alloy Grating Or Grate Drainage Trench Cover Or Manhole Cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

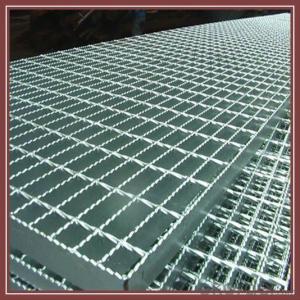

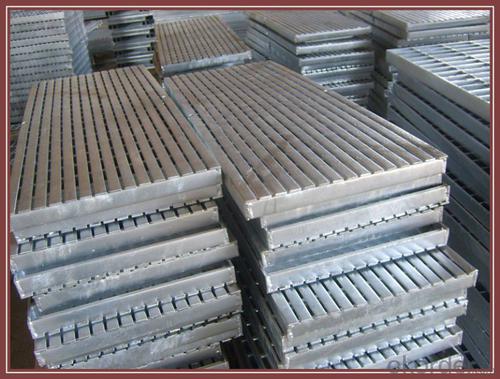

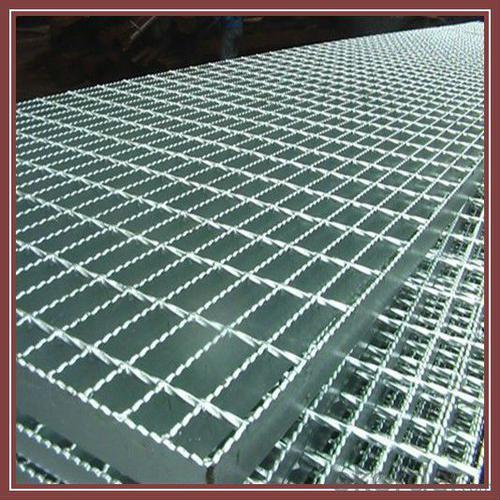

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can aluminum sheets be used for electrical connectors?

- Yes, aluminum sheets can be used for electrical connectors. Aluminum is a highly conductive material and has excellent electrical conductivity. It is commonly used in various electrical applications, including connectors. Aluminum connectors are lightweight, durable, and cost-effective compared to other materials such as copper. However, it is important to consider certain factors such as the type and size of the connection, the amount of current to be carried, and the environment in which the connectors will be used. Additionally, proper insulation and protection measures should be taken to prevent corrosion, as aluminum can be susceptible to oxidation. Overall, aluminum sheets can be a suitable choice for electrical connectors, but careful consideration of specific requirements and conditions is necessary.

- Q: Can someone please help me with the resonance structure for AlCl3. When I draw it, the central Al does not have a complete octet. I read that this is usually the case for atoms like Boron and Aluminium who only have three valence electrons. Is this correct? Also, as a follow on question, does AlCl3 display resonance?

- Since aluminum only has 3 valence electrons it will be missing two electrons from its octet. This means that one of the chloride groups must share an extra electron group with the aluminum. Any three of the chlorides can share an extra electron pair with it (i.e. they'll have 2 lines attached to aluminum), so there is resonance. There are 3 to be specific, one for each chloride sharing another electron pair with Al.

- Q: Are aluminum sheets suitable for automotive applications?

- Yes, aluminum sheets are suitable for automotive applications. Aluminum is a lightweight material that offers several advantages for automotive use. Firstly, aluminum is highly corrosion resistant, making it ideal for exterior parts that are exposed to harsh environments. Additionally, aluminum offers great strength-to-weight ratio, meaning it provides high strength while keeping the overall weight of the vehicle low. This leads to improved fuel efficiency and better performance. Aluminum sheets are also easily formable, allowing manufacturers to create complex shapes and designs for various automotive components. Furthermore, aluminum is recyclable, making it an environmentally friendly choice. Overall, the use of aluminum sheets in automotive applications offers numerous benefits, including weight reduction, improved fuel efficiency, corrosion resistance, and design flexibility.

- Q: What are the applications of aluminum sheets?

- Aluminum sheets have a wide range of applications across various industries. They are commonly used in the construction industry for roofing, siding, and cladding due to their lightweight, durability, and corrosion resistance. Aluminum sheets are also utilized in the automotive industry for body panels and structural components, as well as in the aerospace industry for aircraft parts. Additionally, they are commonly found in the manufacturing of household appliances, packaging materials, and electrical equipment.

- Q: Are aluminum sheets lightweight?

- Indeed, aluminum sheets possess a lightweight attribute. Renowned for its low density, aluminum emerges as a favored option for scenarios necessitating consideration of weight. In direct comparison to other metals, such as steel, aluminum emerges as considerably lighter, facilitating effortless handling and transportation. Despite its lightweight essence, aluminum sheets exhibit remarkable strength and durability, rendering them fitting for a diverse array of applications, including but not limited to the aerospace industry, automotive manufacturing, construction, and packaging.

- Q: What are the different surface finishes available for aluminum sheets?

- Aluminum sheets offer a variety of surface finishes, each with its own unique qualities and aesthetic appeal. Some commonly used finishes include: 1. Mill Finish: This is the most basic finish achieved by leaving the aluminum in its as-rolled state, without any further treatment. It has a smooth and shiny appearance, but may have slight imperfections and is not as durable as other finishes. 2. Anodized Finish: Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum sheet. This finish enhances corrosion resistance, improves durability, and offers a wide range of color options. Anodized finishes can be matte or glossy. 3. Brushed Finish: By brushing the aluminum sheet with a fine abrasive material, a textured pattern is created. This finish is commonly used for decorative purposes and provides a unique and attractive appearance. 4. Polished Finish: Polishing the aluminum sheet using abrasive materials creates a smooth and reflective surface. This finish is often used for decorative purposes, giving the aluminum a high-end, mirror-like appearance. 5. Embossed Finish: Embossing involves creating raised or recessed patterns on the surface of the aluminum sheet. This finish is commonly used for decorative purposes, adding texture and visual interest to the material. 6. Powder Coated Finish: Powder coating entails applying a dry powder to the aluminum sheet and curing it under heat. This finish provides a durable and weather-resistant coating, available in a wide range of colors and textures. 7. Patterned Finish: Patterned finishes are achieved by imprinting various designs or patterns onto the surface of the aluminum sheet. This finish is often used in architectural applications, adding visual interest to the material. These examples demonstrate the range of surface finishes available for aluminum sheets. The choice of finish depends on the desired appearance, functionality, and application requirements.

- Q: This question asks for methods to protect aluminum sheets from damage during transportation and storage.

- <p>To prevent damage to aluminum sheets during transportation or storage, follow these guidelines: 1) Use protective packaging such as bubble wrap or padded covers to prevent scratches and dents. 2) Store aluminum sheets in a dry, cool place away from moisture and direct sunlight to avoid corrosion. 3) Stack sheets with soft padding between them to prevent surface damage. 4) Securely strap or brace the sheets during transport to prevent movement and potential damage. 5) Handle aluminum sheets with clean, dry hands or use gloves to avoid leaving fingerprints or oils that can cause corrosion. 6) Ensure that transportation vehicles are clean and dry to prevent any contaminants from coming into contact with the aluminum. By adhering to these practices, you can minimize the risk of damage to aluminum sheets.</p>

- Q: Are aluminum sheets suitable for aviation applications?

- Indeed, aviation applications can make effective use of aluminum sheets. The aviation industry extensively employs aluminum owing to its lightweight nature, impressive strength-to-weight ratio, and ability to resist corrosion. Aluminum finds applications in the manufacturing of aircraft, including critical components like the fuselage, wings, and structural elements. By utilizing aluminum sheets, the aircraft not only gain structural integrity but also experience reduced weight, thereby enhancing fuel efficiency and overall performance. Furthermore, the versatility of aluminum sheets allows for easy shaping and fabrication, making them highly adaptable for diverse aviation purposes.

- Q: Are the aluminum sheets recyclable?

- Yes, aluminum sheets are highly recyclable. Aluminum is one of the most recyclable materials on the planet, and it can be recycled indefinitely without losing its quality. Recycling aluminum sheets requires less energy compared to producing new aluminum from raw materials, which has significant environmental benefits. The recycling process involves melting down the aluminum sheets to extract the metal, which can then be used to produce new aluminum products. Recycling aluminum sheets not only conserves valuable resources but also helps reduce greenhouse gas emissions and landfill waste. Therefore, it is highly recommended to recycle aluminum sheets whenever possible.

- Q: What are the mechanical properties of aluminum sheets?

- Aluminum sheets possess several mechanical properties, including high strength-to-weight ratio, excellent corrosion resistance, good formability, and high thermal and electrical conductivity. They are also non-magnetic and non-toxic, making them suitable for various applications in industries such as aerospace, automotive, construction, and packaging.

Send your message to us

Aluminum Alloy Grating Or Grate Drainage Trench Cover Or Manhole Cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords