Aluminum Kick Plate Coil Price - Aluminium Hot Rolling Coil for Flat Cold Rolling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Hot Rolling Coil for Flat Cold Rolling

Alloy: 1050, 1060, 1100, 1200, 3003, 3004, 3105, 1235, 8011, 8079, 8006, 5005, 5052, 5754, 5083,etc

2) Temper: Free

3) Thickness: ≥3mm

4) Width: 900-2300mm

5) Weight: 7-8 tons per coil

6) Dimensions and weight can be produced according to clients' specifications.

7) Inner Diameter: 505mm, 605mm

8) Packing: Export standard, wooden pallet.

9) Delivery time: 10-20 days

10) Minimum order quantity:20 tons per size.

11) The term of payment: T/T, irrevocable L/C at sight.

12) Surface: Bright

13)Origin: China

2. Application of Aluminium Hot Rolling Coil for Flat Cold Rolling

Aluminium Hot Rolling Coil is raw material of subsequent production of sheet and coils.

3. Feature of Aluminium Hot Rolling Coil for Flat Cold Rolling

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

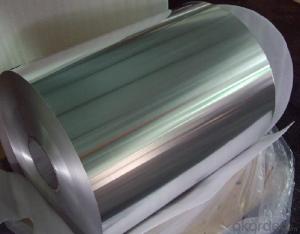

5. Image of Aluminium Hot Rolling Coil for Flat Cold Rolling

6. Package and shipping of Aluminium Hot Rolling Coil for Flat Cold Rolling

eye to sky

eye to wall

with wooden pallet (wooden case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Difference between aluminium roll gate and iron roll gate

- Structurally, there is no difference, but the aluminum roll gate weight is light, the motor needs little effect, save power;

- Q: How do aluminum coils contribute to recyclability in the construction industry?

- Aluminum coils contribute to recyclability in the construction industry by being made from a highly recyclable material. These coils can be easily melted down and reused to create new aluminum products, reducing the demand for virgin materials and minimizing waste. Additionally, aluminum coils are lightweight, making them more energy-efficient to transport and install, further reducing their environmental impact.

- Q: why is aluminum to the right side of the periodic table if it's a metal and why is it negatively charge if it's a mental. also if you combine it with like another metal will it be an ion since its positively charge or no because they are both metals

- It okorder /

- Q: What is the maximum length of aluminum coils?

- The maximum length of aluminum coils can vary depending on various factors such as the specific manufacturing process, equipment capabilities, and industry standards. However, in general, aluminum coils can be produced in lengths ranging from a few hundred feet to several thousand feet. These coils are typically used in applications such as roofing, HVAC systems, and electrical wiring. It is important to note that the maximum length of aluminum coils may also be limited by transportation and handling considerations.

- Q: What are the common surface treatments for aluminum coils in the construction industry?

- Aluminum coils are widely used in the construction industry due to their lightweight, durability, and corrosion resistance. To improve their performance and appearance, various surface treatments are applied. In the construction industry, there are several common surface treatments for aluminum coils: 1. Anodizing is a widely used method that involves creating an oxide layer on the aluminum surface. This process enhances corrosion resistance, improves weather resistance, and provides coloring options. 2. Powder coating is a popular technique where a dry powder is applied electrostatically and then cured under heat. This results in a durable, smooth, and attractive finish that is resistant to chipping, fading, and scratching. 3. PVDF coating is a high-performance option that offers excellent weather resistance and color retention. It is commonly used in architectural applications where long-term durability and aesthetic appeal are desired. 4. Paint coating, using liquid paint, provides a wide range of color options and finishes. These coatings offer good corrosion resistance and can be tailored to specific design requirements. 5. Brushed finish is achieved by brushing the aluminum surface, creating a textured appearance. This process can be done mechanically or chemically, enhancing the aesthetic appeal of the coils. 6. Laminating involves applying a layer of protective film or laminate to the aluminum coil. This safeguards the coil from scratches, stains, and other damage during handling, transportation, and installation. These surface treatments not only enhance the durability and performance of aluminum coils but also offer customization options. Architects and designers can achieve their desired aesthetics while ensuring long-lasting performance in construction applications.

- Q: What are the common sizes of aluminum coils available?

- The common sizes of aluminum coils available vary depending on the specific application and industry. However, some standard sizes include widths ranging from 36 inches (91 cm) to 72 inches (183 cm) and thicknesses between 0.019 inches (0.048 cm) to 0.125 inches (0.318 cm). These sizes are commonly used in industries such as construction, automotive, and manufacturing.

- Q: Can aluminum coils be used in heat exchangers?

- Yes, aluminum coils can be used in heat exchangers. Aluminum is commonly used in heat exchanger applications due to its excellent heat transfer properties, lightweight nature, corrosion resistance, and cost-effectiveness.

- Q: What is the impact resistance of aluminum coils?

- The impact resistance of aluminum coils can vary depending on the specific alloy and temper of the aluminum. Generally, aluminum is known for its good impact resistance due to its inherent strength and ductility. Aluminum coils are often used in applications where they may be subjected to impact or mechanical stress, such as in the automotive industry, construction, or packaging. Aluminum alloys, such as 3003, 5052, or 6061, are commonly used for manufacturing coils. These alloys are known for their high tensile strength, which contributes to their impact resistance. Additionally, aluminum has the ability to absorb and distribute energy upon impact, which helps to reduce the risk of damage or deformation. However, it is important to note that the impact resistance of aluminum coils can also be influenced by other factors such as the thickness of the coil, the surface finish, and any additional protective coatings or treatments applied. Thicker coils generally offer higher impact resistance, while coatings or treatments can enhance the durability and resistance to impact. Ultimately, the impact resistance of aluminum coils can be considered good, but it is always recommended to consult with a manufacturer or supplier to determine the specific impact resistance properties of the chosen aluminum alloy and coil.

- Q: Can aluminum coils be used in the production of automotive heat shields?

- Yes, aluminum coils can be used in the production of automotive heat shields. Aluminum is commonly used in heat shields due to its excellent thermal conductivity and lightweight properties. It helps to effectively dissipate and reflect heat, making it a suitable material for this application.

- Q: Foshan where there are high-quality aluminum and aluminum rolls for sale?

- If you know where to use, or what are the requirements of the words I can occasionally recommend you manufacturers give you, because I am in this industry!

Send your message to us

Aluminum Kick Plate Coil Price - Aluminium Hot Rolling Coil for Flat Cold Rolling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords