7075 Aluminum Sheets for Secondary Continuous Cold Rolling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Coils for Secondly Continuous Colding Rolling

Aluminium Coils for Secondly Continuous Colding Rolling can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Secondly Continuous Colding Rolling

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

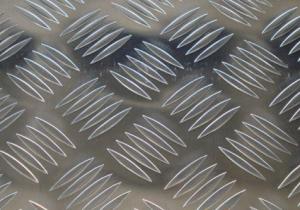

3. Image of Aluminium Coils for Secondly Continuous Colding Rolling

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA1050 | H14 | 0.2-3MM | 1000-1800MM | 2 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are 101 aluminum sheets suitable for chemical processing environments?

- No, 101 aluminum sheets are not suitable for chemical processing environments as they are not corrosion-resistant and may react with certain chemicals, leading to potential damage or contamination.

- Q: why does 10% sulfuric acid not react with aluminum sheet?

- 10% sulfuric acid has a high concentration and will be passivated and formulate a layer of oxide film after reacting with aluminum,and the reaction will stop after seperating sulfuric acid and aluminum. there is a layer of Al2O3 oxide film on the surface of aluminum, so it's hard for sulfuric acid to break the oxide film and react with aluminum.

- Q: Which kind of glue can bond two pieces of aluminum sheets?

- you can use tin welding.

- Q: why does the hardness of 2024 aluminum sheet not increase but decrease after thermal treatment?

- The hardness of 2024 aluminum sheet will decrease after thermal treatment(solution treatment), and it will increase after aging treatment.

- Q: This question asks for a comparison between the benefits and drawbacks of utilizing products made from recycled aluminum.

- <p>Advantages of using recycled aluminum products include reduced energy consumption, lower greenhouse gas emissions, and a decrease in the need for raw material extraction. It also promotes waste reduction and supports a circular economy. Disadvantages might include potential quality concerns, as recycled aluminum might not always meet the same strength and durability standards as new aluminum. Additionally, there can be higher initial costs associated with recycling processes and the need for advanced sorting and processing technologies.</p>

- Q: I saw a nice looking set of cast aluminum pots for a very good price. They feel very heavy. But I remember hearing that aluminum is not healthy so I am wary of buying them. Any advice would be appreciated.

- A lot of aluminum pots these days have a teflon coating. If the pot is plastic-coated, then you won't get any aluminum from it Twenty years ago, there were concerns about aluminum pots because of the aluminum content of alzheimer clumps. But aluminum intake was cleared from worries about alzheimer -- the clumps gather aluminum rather than vice versa. I'm not aware of any more recent health concerns. The first link below claims that the anodizing process that hardens the surface of the pot, also locks in the metal so that none gets into the food. In the second link, Planet Grean (part of Discovery Channel) says that you're allowed 50 milligrams per day, and even using non-anodized aluminum cookware would give you five or six. But they say not to cook acidic foods, store food in the pot, or keep using the pot after a major scratch in the hardened surface. In the third link, Treehugger (also part of the Discovery empire) says that you get more aluminum from your drinking water than from aluminum cookware. (Alum is used to settle sediment in big-city water supplies.)

- Q: Are there any formulators out there that have any ideas on putting together a cleaner that removes carbon (baked on grease) from an aluminum pan without attacking the meatal itself?? Ive been thinking about this problem for a while and would appriciate any ideas you guys might have. Thanks

- try GOJO hand cleaner with a Sung. you dont need to scrub hard and it will remove the baked on grease.

- Q: I just built a stone wall with illuminated glass features embedded, and to make them shine evenly, I had all sides but the visual one wrapped in industrial thickness aluminium foil. One week later, the foil has disintegrated. I have used type 10 Portland. What is going on?

- I believe your problem is that concrete acts as a fairly strong base (this is especially true of mortar mixes). It is well known that strong base will react with an active metal like aluminium and produce hydrogen gas as a byproduct. The representative reaction is: 2Al+6NaOH==2Na3AlO3+3H2, This reaction is fairly rapid and can even cause an explosive buildup of hydrogen gas in a non-ventillated area.

- Q: What is the fatigue life of aluminum sheets?

- The endurance capacity of aluminum sheets pertains to the number of cycles the material can endure before failure arises under cyclic loading circumstances. Various factors, including the composition, thickness, surface finish, loading conditions, and environmental elements, can cause the endurance capacity of aluminum sheets to differ. Aluminum is renowned for its relatively high fatigue strength in comparison to other materials, rendering it a favored option in industries like aerospace, automotive, and construction. The endurance capacity of aluminum sheets is typically influenced by the presence of microstructural flaws, such as inclusions, voids, and grain boundaries. Fatigue tests are conducted, utilizing standardized procedures like ASTM E466 or ASTM E606, to ascertain the endurance capacity of aluminum sheets. These tests entail subjecting the material to cyclic loading conditions, usually at a consistent stress or strain amplitude, while monitoring the number of cycles required for failure to arise. The outcomes are then employed to generate an S-N curve, which represents the connection between the applied stress or strain amplitude and the number of cycles until failure. The S-N curve furnishes valuable insights into the endurance capacity of aluminum sheets, indicating the stress or strain levels at which the material can withstand a specific number of cycles before failure. It is crucial to note that the endurance capacity of aluminum sheets can be enhanced through various approaches, such as alloying, heat treatment, surface treatment, and appropriate design considerations. To conclude, the endurance capacity of aluminum sheets plays a pivotal role in the design of components or structures exposed to cyclic loading conditions. By comprehending the specific properties and characteristics of the aluminum alloy, coupled with proper testing and analysis, it is possible to ascertain the endurance capacity and guarantee the safe and dependable performance of aluminum sheets in diverse applications.

- Q: What is the color range available for aluminum sheets?

- The color range available for aluminum sheets is quite diverse and extensive. Aluminum sheets can be found in a variety of standard colors, including but not limited to silver, black, white, bronze, and gold. Additionally, aluminum sheets can be coated with various finishes, such as anodized, painted, or powder coated, which can further expand the color options. These coatings can provide a wide range of colors, including vibrant shades like red, blue, green, yellow, and more. Furthermore, custom colors can also be achieved through specialized processes, allowing for personalized and unique color choices. Overall, the color range available for aluminum sheets is extensive and flexible, catering to various aesthetic preferences and design requirements.

Send your message to us

7075 Aluminum Sheets for Secondary Continuous Cold Rolling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords