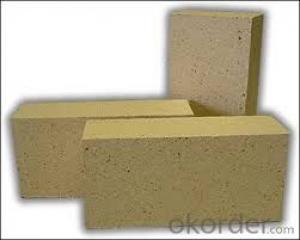

High Alumina Silica Refractory Bricks for Electric Arc Furnace Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Alumina-silica Refractory Bricks Used In Electric Arc Furnace Roof4

Manufacture

Low price.

Looking for lo

Alumina-silica Refractory Bricks Used In Electric Arc Furnace Roof

Here we can help you find the most suitable one to meet your needs.

No waste! No extra cost! No cheat! All we are doing is trying to save your cost!

We can't say we are No.1 in China, but we are trying to be the No.I in mind of our clients!

If you are interested in this kinds of products,welcome view our website. high temperature insulating bricks

All I want to tell you is:please have a "taste",just like as taste a cup of coffee, talk with our sales,then you'll know whether we are your idea supplier or not.

All of your inquiry will be attentioned promptly!

the follows are some detail parameters of our products,in order to save your time,we just show you the datas

fire clay brick for various kilns

Characteristics:

Fireclay brick is made from clinker clay by mixing, forming, drying, sintering and matching characterized by good resistance to corrosion and abrasion, good thermal shock resistance, good spelling resistance, high mechanical strength, good volume stability under high temperature.

Specifications

1. for Glass Melting Furnace

2. High quality and best price

3. Chemical stability

4. ISO9001:2000

5. Timely deliver

Applications: Metallurgy, building materials, chemical industry, petroleum, machinery manufacturing, silicate, power and other industries.

Physical andChemical Indicators:

Items | Index | ||||||||

N-1 | N-2a | N-2b | N-3a | N-3b | N-4 | N-5 | N-6 | ||

Refractoriness, °C ≥ | 1750 | 1730 | 1730 | 1710 | 1710 | 1690 | 1670 | 1580 | |

Refractoriness Under Load,°C, [0.2MPa×0.6%] ≥ | 1400 | 1350 | -- | 1320 | -- | 1300 | -- | -- | |

Linear Change on Rehearting,% | 1400°C×2h | +0.1 -0.4 | +0.1 -0.5 | +0.2 -0.5 | -- | -- | -- | -- | -- |

1350°C×2h | -- | -- | -- | +0.2 -0.5 | +0.2 -0.5 | +0.2 -0.5 | +0.2 -0.5 | -- | |

Apparent Porosity, % ≤ | 22 | 26 | 24 | 24 | 26 | 24 | 26 | 28 | |

30.0 | 20.0 | 25.0 | 20.0 | 15.0 | 20.0 | 15.0 | 15.0 | ||

- Q: What is the heat preservation material used in a laboratory furnace?

- Asbestos, high alumina brick, or carbonized silicon are often used.Thermal insulation materials are generally used to guide heat coefficient less than or equal to 0.2 of the material. Thermal insulation material development is very fast, and in industry and building the use of good insulation technology and materials, often can get twice the result with half the effort. Each ton of mineral cotton insulation used in the building saves one ton of oil a year.

- Q: What are the main components of high alumina bricks?

- Sweat is like water mineral alumina bauxite, aluminum ore, magnesite, waves of gibbsite. Anhydrous alumina raw material, such as corundum, alumina, fused corundum. High alumina brick Zhengzhou gold company specializing in the production of various specifications, you can directly ask their technical staff.

- Q: How much is one ton of high alumina refractory brick?

- Three high aluminum refractory brick Zhengzhou Kuwait is generally around 800. 32 years of experience, good.

- Q: What is the price of the latest thermal insulation material?

- Also through online pre understand the products and prices, and now have large-scale manufacturers are generally opened on the cable business. Goods than three, manufacturers on-site inspection, confirm the quality of goods after considering cooperation.

- Q: How are the high alumina bricks fired?

- According to the quality requirements of different grades of high alumina brick, choose different grades of bauxite raw materials, it is conducive to rational use, fine materials, fine distribution, as far as possible not to use mixed grade severe raw materials. The quality of the clinker depends on the calcination temperature, calcination temperature, sintering temperature should be generally reached or slightly higher than that of alumina clinker sintering, to ensure the full and possible high volume density, and the two secondary Mullitization and sintering shrinkage effect in calcination process. Lightweight high alumina brick, also known as high aluminum insulation brick (high-aluminium heat insulating brick). A lightweight refractory consisting of mullite and glass phases or corundum in excess of 48%. The volume density is 0.4 ~ 1.35g/cm3. The porosity is 66% ~ 73%, and the compressive strength is 1 ~ 8MPa. Better thermal shock resistance.

- Q: What materials are used for roof insulation?

- There are two kinds: one is a kind of cotton insulation board, such as rock wool board, aluminum silicate cotton board, but this is not environmental protection, harmful to life, foam board (this fire safety factor minimum), these relatively cheap.

- Q: Can high alumina brick resist carburizing?

- The key is to look at the content of Fe3O2 metal oxides (so-called anti carburizing brick generally refers to the content of Fe3O2 less than 1% clay brick and Gao Lvzhuan) just a photo shoot, out for everyone to see, high alumina brick common in reductive atmosphere has been chalking up.

- Q: The difference between ordinary and diatomite brick refractory brick

- Refractory brick belongs to a large class, according to different materials used are divided into: high alumina brick, dolomite brick, magnesia chrome brick, magnesia spinel brick, phosphate brick, carborundum brick, brick, mullite bricks etc..

- Q: Use of high alumina refractory bricks?

- High alumina refractory brick in Al2O3 more, close to neutral refractory material, can resist acid slag and alkaline slag erosion, because it contains SiO2, so alkaline slag ability than acid resistance slag ability less.It is widely used in building blast furnace, hot blast furnace, furnace top, blast furnace, reverberatory furnace and rotary kiln lining. In addition, high alumina bricks are widely used as furnace regenerative checker, pouring system for plug nozzle, etc..

- Q: Which thermal shock stability of clay brick and high alumina brick is good?

- Generally, the thermal shock resistance of high alumina brick products is worse than that of clay brick products

Send your message to us

High Alumina Silica Refractory Bricks for Electric Arc Furnace Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords