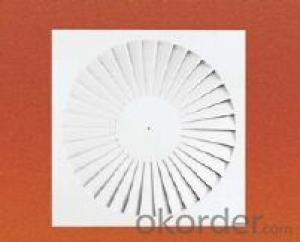

air condition vent mold Exhaust Air Valve

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description Air Condition Vent Mold Exhaust Air Valve for Construction or building

Air condition vent mold Exhaust Air Valve Is Engineered polymer construction, Three-way deflection,Traditional styling,Integral multi-shutter damper with easy to use damper handle For heating or cooling applications

Specifications of Air Condition Vent Mold Exhaust Air Valve for Construction or building

Exhaust Air Valve

Made of Galvanized Steel

exhaust air valve

Size 80, 100, 125, 160, 200mm

Removable core, with collar

Exhaust Air Valve

Material: Galvanized Steel

Finish: White powder coated

Size: 80mm, 100mm, 125mm, 160mm, 200mm

Removable core, with collar

For ceiling air supplying

Easy installation, and good performance

Packaging Detail: Standard export packing ,Your requirment accept.

Delivery Detail: 3-5 weeks

Advantage of Air Condition Vent Mold Exhaust Air Valve for Construction or building:

1.Competitive price.

2.Continuance service and support.

3.Diversified rich experienced skilled workers.

4.Custom R&D program coordination.

5.Application expertise.

6.Quality,reliability and long product life.

7.Mature,perfect and excellence,but simple design.

Feature of Air Condition Vent Mold Exhaust Air Valve for Construction or building

Engineering capabilities include:

1.Parts design.

2.R&D products.

3.Prototype design and production assembly.

4.Reputable design software used for all design work.

5.Hot runner design.

6.Cold runner design.

7.Fast automatice remould design.

8.Mold design with a team of experienced specialists.

Process of our company :

1.Quote competitive price according customer detail requirement.

2.Sign agreement.

3.Customer T/T deposit to us to start to design mould.

4.Send mould drawing to customer for confirmation.

5.Mould design confirmed and start to make mould.

6.Make mould trial during tooling time (which we get agreement with customer)

7.Send mould trial sample to customer for inspection.or customer come to our factory to inspect mould personally.

8.Customer T/T balance to us after mould confirmed.

9.Deliver mould after get balance.

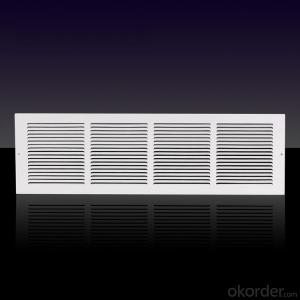

Application of Air Diffusing Grille for Construction or building :

It is mostly used on the sidewall outlet type air distribution. We always export to supermarket to USA ,CHILE ETC. For heating or cooling applications.

FAQ :

1.What is the air grille?

It is made of plastic (ABS PVC,PP PE)or steel metal ,aluminum steel by mould. It could be used for sidewall ,outletype air distribution, heating or cooling applications.

2.what kind of grille we have ?

We have ABS /PP/ PVC Plastic Air Diffusing Grille, aluminum swirl air diffusers, floor register, return air grille , wooden register ,plastic air grille, aluminum air grille, baseboard registers, celling side way registers, plastic air vent, blades dampers, etc .

3.what is the application of our grilles?

It could be used for sidewall ,outletype air distribution, heating or cooling applications.

4. what kinds of design we have ?

Please check our catalogue or website for reference. Or we could make design as your ideas . We have professional technical team . they could make what you imagine.

- Q: How to deal with the liquid hammer phenomenon of compressor

- If the compressor has occurred abnormal impact (knock or impact) sound, and will strongly shake vibration, indicating that the liquid is in the attack. Slight short term abnormal shocks may be of little concern, but often prolonged and heavy fluid shocks cause compressor deformation, rupture, and even breakage, which directly damages the compressor

- Q: What is the purpose of a two-stage compression refrigeration cycle?

- The traditional air conditioning system can only achieve the lowest heat at minus 7 degrees Celsius environment itself, and adopting the two-stage inverter air conditioner double stage compressor can be achieved in the limit condition minus 30 DEG C under strong heating

- Q: What are the air compressors for?

- The food and pharmaceutical industries use compressed air to stir the slurry

- Q: What is the function of the refrigerator compressor?

- Refrigerator is the use of evaporation, refrigeration or gasification absorption of heat to achieve the purpose of refrigeration

- Q: Refrigerators do not cool, compressors do not work, but very hot, what is the reason?

- For the refrigerator electronic control system, in the case of electricity, with a multimeter measuring AC voltage blocking main control board of the input voltage and the output voltage is normal, the screen to show whether the compressor work? Each sensor is normal or not? The contact normal? If the input voltage and output voltage is normal without the main control board a fault

- Q: What are the technical parameters of the compressor?

- The exhaust heat is the sum of the equivalent heat of the compressor's refrigerating capacity and part of the compressor's input power, which is discharged through the condenser in the system. This parameter is a very important performance index for the compressor in the heat pump system. It is also necessary to design the condenser of the refrigeration system.

- Q: What are the differences and characteristics of D M type V compressor?

- V is generally used in multi cylinder, large, high speed. The utility model has the advantages of full utilization of space, good heat dissipation and stable operation. Requirements for technical content is relatively high

- Q: How to repair air conditioning compressor?

- The compressor power supply line card is generally burned, long time working in load condition caused by compressor, high current operation, the surface temperature of the compressor is higher. After dealing with the terminal fault, check the damage reason of the compressor terminal, the condenser fouling, the outdoor fan speed and the compressor capacitor will cause the compressor to run at high current and the surface temperature is too high

- Q: What are the condensers made of?

- Of these, the evaporator is a device for conveying cold capacity. The refrigerant absorbs the heat of the cooled object in it to achieve refrigeration. The compressor is the heart that acts as a suction, compressor, and refrigerant vapor

- Q: How many types of drive are there in an air conditioner compressor?

- At present, scroll compressors have absolute advantages in the field of cabinet air conditioners. In the field of automotive air conditioning, the refrigeration coefficient of scroll compressor has reached 2, showing a strong competitive edge. The development of scroll compressor is to expand its refrigeration range, further improve efficiency, use alternative refrigerants and reduce manufacturing costs and so on.

Send your message to us

air condition vent mold Exhaust Air Valve

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords