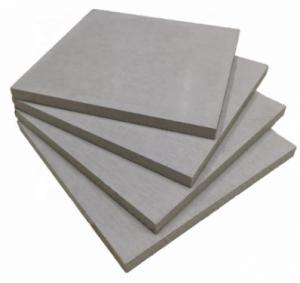

A1 Degree non-combustion fiber cement board 6mm,9mm,12mm price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber cement board

Description of the fiber cement board:

Fiber cement board is a composite material made of sand,cement and cellulose fibers. Fiber cement board is manufactured in a sheet form and is used not only as cladding but also commonly used as an eave lining and as a tile underlay on decks and in bathrooms and other places.

Parameters of our fiber cement board:

| Item | Result | Test method |

| Density | 1.2~1.4g/cm3 | Density test |

| Imcombutibility | Eligible | Imcombustibility test |

| Bending strength | 10.5Mpa | Bending strength test |

| Modulus of elasticity | 1.3*10^4 | Modulus of elasticity test |

| Asbestos content | None | Asbestos content test |

| Frost resistance | Eligible | Frost resistance test |

| Water absorptivity | 0.4 | Water absorptivity test |

| Thermal shrinkage | 0.43 | Thermal shrinkage test |

| Welling rate | 0.02% | Welling rate test |

| Radioactivity | IRa 0.1 | Radioactivity test |

| Ir 0.2 |

The main advantages of our fireproof fiber cement board:

Fiber cement board is Class A1 fireproofing, neither toxic gas emission , nor black smoke in case of buming Standardized production of the product fiber cement board, site assembly and easy installation

Fiber cement board is No dust emission , no dust generation , non-oxidation, mold prevention, insect prevention and moth prevention

Fiber cement board is Acid and alkali resistance , chemical resistance

Fiber cement board is Wear resistance, easy cleaning, low maintenance cost

Fiber cement board is Antibacterial surface

Fiber cement board is Environmental friendly, no VOC gas when installation

Fiber cement board is Large effect, elegant appearance, less gap and favorable to cleaning

Fiber cement board is Low thermal conductivity and favorable to heat insulation and energy saving

Fiber cement board is Surface diffuse reflection and not reflective

Fiber cement board is Good durability and long service life

Fiber cement board is Bright apperance and rich color gives us a feeling of cleanliness and warmth

Non-asbestos siding fiber cement board

Refractory temperature:1770-2000°C

Grade: A1 incombustible

Thermal conductivity: 0.03

Material: cellulose fiber

Shape: rectangle

Form: flat sheet

Size: 2440*1220*(4-40)

Product categories: fire prevention board

Flexure strength: 14

Operating temperature: normal temperature

Introduction

Non-asbestos fiber reinforced calcium silicate board is low shrinkage fiber cement preesure board which uses cement, quartz, lime, fly ash, cellulose fiber, inorganic fiber and other materials as main material, manufactured by advanced technology and techniques to form green sheet, and then pressed by thousands tons pressure, cured by high temperature and high pressure steam and other special treatment.

Product feature

Fire prevention, waterproof, high strength, corrosion resistance, heat insulation, sound insulation, durable, long service life, safe and convenient construction.

- Q: Cabinet door environmental protection grade how to divide

- Cabinet door of the substrate if it is a density board, then its highest environmental rating is E1 level, and like the double-sided surface of this substrate is the particle board can reach the highest standards of Japan JIS four standard environmental standards

- Q: 2017 plate top ten brands

- China top ten gypsum board brand 1 king coconut (China's well-known trademarks, the Chinese brand 500, China's top ten brands of wood, the first Chinese woodworking board brand, Hangzhou King coconut holding) 2 Albert CHAN (Guangdong famous brand, specializing in the production of environmentally friendly plywood wood products of large enterprises, Guangzhou City is Granville Wood Products Co., Ltd.) 3 Tailmei (German technology, German equipment, China 's top ten gypsum board brand, China' s environmental labeling product certification, Hubei famous brand. 4 North New Building Materials (China Famous Brand, China Top Ten Gypsum Board Brand, China Top Ten Brand, China Famous Brand, China Gypsum Board Industry First) 5 Lafarge (green building materials, Lafarge Group (French brand), Lafarge has the world's leading building materials R & D facilities) 6 Taishan (China Famous Brand, China Famous Brand, Taishan Gypsum Co., Ltd. is a national key new building materials production enterprises) 7 Saint-Gobain (global gypsum board share first, global gypsum powder share first, global ceiling share third, Saint-Gobain Group) 8 can be resistant (top ten gypsum board brand, Germany can be resistant to international companies with its innovative solutions to occupy the industry leading position from the development) 9 Jason (top ten gypsum board brand, green building materials, Jason gypsum board group company to invest in China, serve the global construction market!) 10 Bayer (Shandong brand name products, top ten gypsum board brand, Shandong Bayer Group for the human to create a beautiful living environment)

- Q: What is the smart sheet?

- Smart sheet can be interpreted as intelligent sheet metal, King coconut latest release of intelligent paint-free board is smart sheet 1, intelligent simulation Using a selection of 5A-class model to ensure that each piece of intelligent paint-free board standards the best; Mianqi the surface of the impregnated film coated paper, using a digital scanning, digital imaging, digital printing technology to ensure that the finished color texture clear and realistic. 2, intelligent security Joined the UV hidden map recognition, digital layer security, intelligent information reading, physical visual security of the four recognition system to ensure that every user can rest assured that the use of King coconut products. 3, intelligent customization Choose the most representative, to undertake China's thousands of years of wood culture of natural precious wood varieties, and synchronized supporting the decorative lines and hardware, customized for consumers to enjoy the private sector, for the vast number of consumers to create a multi-functional intelligent home Living space, its beauty is no less than a variety of finished furniture. 4, intelligent experience: Through the Tablet PC, mobile phones, computers and other tools to show a variety of styles and style effects, to eliminate the consumer in the selection of the concerns, bring the sheet industry in the unprecedented ease and convenience.

- Q: Recently we received a lot of customers to reflect, said to buy their own snowflake sheet, the results go back after use, the taste is great, even worse, the board labeled furniture has not long, there has been damp deformation situation. Customers are very angry, we are also confused.

- Recently we received a lot of customers to reflect, said to buy their own snowflake sheet, the results go back after use, the taste is great, even worse, the board labeled furniture has not long, there has been damp deformation situation. Customers are very angry, we are also confused. However, it is the most environmentally friendly sheet on the market, and the formaldehyde emission of the E1 grade (0.5 <formaldehyde emission <1.5) sheet is similar to that of the same type of sheet, although the plate price is relatively high. The brand claims to be the E0 level release standard. Many customers are directed at the brand of snow. We do is the conscience of business, bright business, snow shop in the flagship store sold to our customers are the lowest price, the floor is very low profit, are by running the amount to earn meager profits, of course, each A sheet of hair issued to the we are checked, and will never appear cracks, flaws. In the flagship store to buy Xuefeng ecological board, we will carefully selected for the customer out of the same batch of goods, to ensure a high degree of unity of the panel color. Will never appear shoddy situation to deceive consumers, which is undoubtedly pick up the stone hit his feet, we will never make this self-destructive brand image of the act. We compare the documents, compared to the decorating company, and finally concluded: these customers are not buying snowflake sheet. Now the market is not a lot of qualified small decoration company, the name of the shiny brand name, to higher than the price of ordinary plate, to sell the brand of wooden plywood, often do not understand the decorating industry customers Deceived, which is our snow brand is also a damage.

- Q: I went to the furniture market to see the production of furniture with a solid wood, the second is the plate. Solid wood is well understood, that plate is what, there are several? Which is better

- Generally divided into solid wood and man-made sheet. Solid wood is a natural solid wood sheet, this is easy to understand. Man-made sheet is divided into many categories. 1, multi-layer plywood. 2, Blockboard is the big core board. 3, high density board fiberboard (high density board) 4, solid wood particle board. 5, particleboard. 6, moisture board and so on

- Q: How to do the corn stalks

- Process Technology Line: 1. Straw density plate: Air dry straw → impurity removal → cut off → wind selection (blown out of the heart) → cans → high pressure steam → spray → fine → spray → drying → pavement → preload → hot pressing → edge → cutting → packaging → finished product 2. Straw crushed plate (particleboard) Drying Straw → Cutting → Wind Selection → Recovering → Drying → Screening → (Surface Layer, Dust, Core Material) → Mixing → Pavement → Preloading → Hot Press → Edge → Cutting → Inspection → Packaging 3. Straw composite board Straw → Cutting → Steam Blasting → Mixing → Paving → Wood Veneer → Glue → Preloading, Hot Press → Side → Varnish → Sanding → Finished 4. New wall materials: Corn stover high grain straw → election → leaves → cut → pavement → irrigation → do the surface layer → veneer → sanding → finished In addition to the above processing, the straw can also be used for pulp making after steam blasting, which is about a third less expensive than traditional pulping methods and only one third of the traditional method. It is helpful to solve the problem of pulp gap caused by the forced cessation of small papermaking by the state. Fourth, the main technical key and expected to achieve the technical and economic indicators: 1. Main technical key: ① developed as low as possible, environmentally friendly, waterproof superior, infiltration of a good name of the glue. ② design and improvement of grading pavement. ③ steam blasting equipment selection and the determination of the main process parameters. ④ hot pressing and cold pressing process parameters adjustment. 2. Expected technical and economic indicators: ① adhesive; solid content: 60% -65% ??????????Free formaldehyde content: 0.2% or less ??????????Viscosity: coated with 4 cups: 30 ℃ 10-20 seconds (fiberboard) ?????????????????????????????????50-65 seconds (particle board)

- Q: Is the molded sheet a green sheet?

- Molded plate is the plastic plate, has been the European kitchen and bathroom, bathroom furniture door of the mainstream material, the domestic enterprises since 1997 began to use in the product. Looking for environmentally friendly sheet can go to China plate trading online to see.

- Q: How is the environmental standard of the plate defined?

- The country has not yet officially released on the E0 level of national standards, the current so-called E0 standard for the industry's most common convention.E0 means: less than or equal to 0.5 mg / l of formaldehyde emissionE1 refers to: less than or equal to 9.0mg / 100g formaldehyde emissionE2 means less than or equal to 30.0 mg / 100 g of formaldehyde emission

- Q: Not the best material if the material is certainly K gold and then titanium and the like plate metal is conventional glasses frame is not a good argument of course the same material brand bigger work is certainly better

- Not the best material if the material is certainly K gold and then titanium and the like plate metal is conventional glasses frame is not a good argument of course the same material brand bigger work is certainly better

- Q: MD board has no E1 level

- MDF has E1 level There are three kinds of formaldehyde content measurement method - perforation extraction method, climate box method and dryer method. Domestic according to the calculation of formaldehyde content is divided into E1, E2 level. E1 grade formaldehyde emission less than 1.5MG / L, can be used directly in the room; E2 level formaldehyde emission is less than 5MG / L, generally only for outdoor use, indoor use must be closed treatment. Ex grade formaldehyde emission is greater than 5MG / L, indoor can not be used. The market has said E0 level, which can be said to be pure broken speculation, the domestic and not the actual test certificate.

Send your message to us

A1 Degree non-combustion fiber cement board 6mm,9mm,12mm price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords