A large number of inventory foam

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CONSTRUCTION:

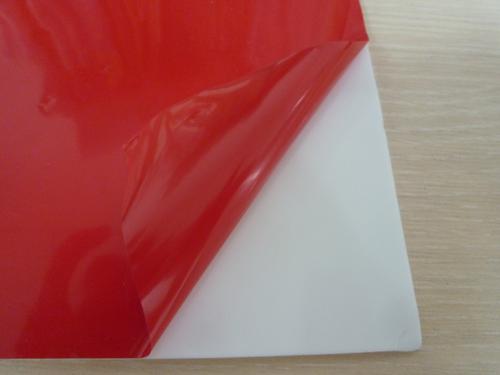

Carrier: Acrylic foam

Liner: PE film, red colour.

TYPICAL PHYSICAL PROPERTIES:

Color: White

Total Thickness: 0.64mm ± 50 micron

180°Peel Adhesionafter 20 minutes (gf/25mm):2,500

180°Peel Adhesionafter 24 hours (gf/25mm):3,500

TemperatureTolerance :100℃

(24 hoursconditioning at indicated temperature with 100g static load)

PACKING:

Jumbo Roll:0.800 x 33m

Packaging:Wrapped with corrugated cardboard.

REMARKS:

1. The data above are typical results and subject to change withoutnotice.

2. Tolerance: Weight and Thickness: ±5%; Width: ±5mm;

Length: Cut Roll & LogRoll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be storedat room temperature and be kept away wet and/or heat source.

4. It is essential, as with allpressure-sensitive tapes, that the surface to which the tape is applied must beclean, dry, and free of grease and oil.

5. The users should take test anddo trial-application on the above products before coming into application so asto witness and ensure suitability for their special purpose and technique.

- Q: Which is better waterproof performance, neoprene or silica gel?

- High temperature silicone rubber is mainly used for making all kinds of silicone rubber products, while room temperature silicone rubber is mainly used as adhesives, potting materials or dies. The maximum amount of heat curing type, heat curing type and methyl silicone rubber (MQ), methyl vinyl silicone rubber (VMQ, dosage and product grades at most), methyl vinyl silicone rubber (PVMQ low temperature resistance and radiation resistance), there are other eyes of silicone rubber, fluorine rubber and so on.

- Q: What is the difference between silicone rubber and silicone rubber?

- Silica gel is a kind of analysis called silica aggregate because he has a special chemical properties in various fields so we found it a synthetic rubber chemical, this also let a lot of friends on the silica gel cognition have a certain understanding, but the difference between silica gel and silicone rubber, we may know little, according to since 1916 the American chemist invented its performance and the effect of silica gel has been studied for many years continuously since the development of silicone industry is more and more widely, and the silica gel and silicone rubber used a different name for different parts!

- Q: Are rubber products poisonous? What harm?

- There are many kinds of rubber, is not toxic, but in the process some people will add some material in contact with the skin, eat will produce adverse reactions, carcinogenicity, until poisoning.

- Q: What kind of rubber coated aluminum alloy (metal) better

- White Silicone, or at cyanide rubber, you have to brush the surface of metal binder, general is muruk we do, rubber products, these things often encounter

- Q: How to maintain and store the rubber material?

- Rubber itself is a shelf-life, you can ask the supplier to warranty, above all, as fillers, such as calcium carbonate, carbon black, long time no problem, also have a shelf life of antioxidant promoter, especially individual species. When storing, pay attention to fire prevention, moisture-proof, away from the high temperature, avoid direct sunlight, of course, the general "first in first out" is a must follow the truth.

- Q: How to remove the peculiar smell of rubber products?

- Water - based deodorant is mainly an oil - based water - borne agent, which reduces the flavor of rubber products when neutralized with rubber raw materials. This method is not thorough and effective, generally lasting within one month.

- Q: How to clean rubber products?

- Rubber is elastic hot melt thermosetting body, plastic is hot cold setting. Rubber due to different types of sulfide species, its molding and curing temperature range is also a considerable gap, and even can be affected by climate change, indoor temperature and humidity affected. Therefore, the production conditions of rubber products need to be adjusted at any time. If not, the quality of the products may be different.

- Q: For the application of common synthetic rubber, not too long or too difficult, want to do

- Polybutadiene rubber (BR) is formed by polymerization of butadiene rubber CIS structure. The advantages are: flexibility and excellent abrasion resistance, good aging resistance, low temperature resistance is excellent in heat under dynamic load is small, easy to metal bonding. The disadvantage is low strength, tear resistance, processability and self-adhesive poor. Using temperature range: - 60 DEG C ~ + 100 DEG C. The general and natural rubber or butadiene rubber and tire tread, main production and transportation with cold and special products.

- Q: What is rubber leather?

- High elasticity polymer. The word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process (see photo). In 1770, British chemist J. Priestley discovered that rubber could be used to erase pencil writing. The material used at that time was called rubber, which has been used so far. The molecular chain of rubber can be crosslinked, and the crosslinked rubber can recover quickly when it is deformed by external force, and has good physical and mechanical properties and chemical stability. Rubber is the basic raw material of rubber industry. It is widely used in making tyres, rubber hoses, tapes, cables and other kinds of rubber products.

- Q: What is the rubber composition and function of the airplane tyres?

- Ethylene propylene rubber and ethylene propylene rubber are synthesized with ethylene and propylene as main raw materials. They are resistant to aging, electrical insulation and ozone resistance. Ethylene propylene rubber can be filled with oil and filled with carbon black. The price of the product is low, and the chemical stability of the ethylene propylene rubber is good. The abrasion resistance, elasticity, oil resistance and the proximity of styrene butadiene rubber are close. Ethylene propylene rubber is widely used. It can be used as tyre, sidewall, rubber strip and inner tube, as well as parts of automobile. It can also be used as wire, cable sheath and high voltage and extra high voltage insulating material. Can also manufacture rubber shoes, sanitary products and other light colored products. It is a chloroprene rubber as the main raw material, made by homopolymerization or copolymerization of small amounts of other. Such as high tensile strength, heat resistance, light resistance, aging resistance and oil resistance properties are superior to natural rubber, styrene butadiene rubber, butadiene rubber. It has a good flame resistance and excellent resistance to burning, its chemical stability is high, water resistance is good. Chloroprene rubber is electrical insulation, cold resistant performance is poor, rubber is not stable in storage. Neoprene is widely used, such as the manufacture of transport belts and belts, wires and cables, and the manufacture of oil resistant hoses, gaskets, and chemical resistant equipment linings.

Send your message to us

A large number of inventory foam

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords