7.5kw 380v 3 phase variable frequency drive ac motor controller

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Brand:CHINSC

2.37kw variable frequency drive

3.MOQ:1 set

4.Best price and quality

5.Quick delivery time

Technical Specification

Item | Specification | |

Input | Rated voltage | T4 series: Three phase 380v, ±15% |

Frequency | 50/60Hz ±5% | |

Output | Voltage | Three phase 0-380V |

Frequency | 0-600Hz | |

Overload ability | Type G: 150% rated current for 1 minute, 180% rated current for 2 second; Type P: 120% rated current for 1 minute, 150% rated current for 2 second. | |

Heat Dissipation | Cooling type | Forced Cooling |

Temperature protection | Heatsink temperature >85degree trip protection against overheat | |

Fan control | Heatsink temperature> 50degree, fan forced operation, frequency inverter continue work | |

Control Performance | Control mode | Open-loop vector control, V/F control, Torque Control |

Start torque | Open-loop vector control: 0.5Hz 180%; VF control:0.5Hz 150% | |

Speed range | Open-loop vector control: 1:200; VF control:1:100 | |

Speed control precision | Open-loop vector control: ±0.2%; VF control:±0.5% | |

Torque control precision | Open-loop vector control: ±5% | |

Torque response time | Open-loop vector control: <20ms< span=""> | |

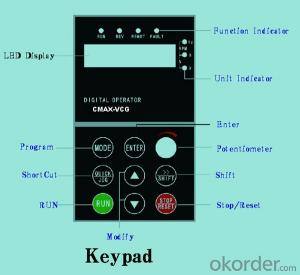

Function | Channel of operation command | Keyboard control,terminal control,communication control |

Start mode | Direct start, DC injection braking before start, speed tracking before start | |

DC injection braking | Start DC injection braking, stop DC injection braking | |

Dynamic braking | Built-in braking unit < = 11kw, get external braking unit>15kw | |

Frequency source choice | Keyboard digital frequency setting, analog V1 setting, analog V2 setting, Keyboard potentiometers setting, Multiple speed operation setting, PID control setting, telecommunications setting, PLC program operation setting, HDI High Speed Pulse setting | |

Main and auxiliary frequency combination set | Just main frequency setting, just auxiliary frequency setting, QUICK/JOG or terminal switching selection, main frequency + auxiliary frequency, main frequency - auxiliary frequency, maximum, minimum, could realize Frequency overlay and fine adjustment function | |

Frequency resolution | Keypad setting:0.01Hz; Analog setting: 0.1% | |

Carrier frequency | 0.5Khz~15.0Khz, both PWM mode could be chosen | |

Acc/Dec time | 0.1~3600.0s | |

Multiple VF curve | Linear V/F curve, 2.0 times power drop torque V/F curve, custom V/F percentage (can realize manual energy saving control), multipoint VF curve. | |

Built-in PID | Built-in PID controller, apply to process control occasion such as water or gas supply. Meanwhile the sleep wake up function could save energy to the great extent possible. | |

Simple PLC operation | 16 segment goal setting, frequency or mode of percentage setting could be chosen, each segment of operation time and direction could be set separately, and realize timing stop function. | |

Common function | Speed tracking, Cut-off restart, fault recovery, Automatic torque promotion, the motor’s parameters auto-learning, Pendulum frequency operation, hopping frequency, UP/DOWN control, AVR, Over-voltage stalling protection, rapid current-limiting, Instant power down and drop frequency operation | |

Input Output Signal | Analog input | V1:0~10V V2:4~20mA or 0~10V, Select through JP2 jumper Keyboard potentiometer input: 0~5V |

Analog output | FM1:0~10V or 0~20mA, Select through JP9 jumper FM2:0~10V or 0~20mA, Select through JP10 jumper. Need the support of SC-EXT1-IO expansion cards | |

Digital input | Standard configuration S1~S6, can expand S7~S10 through SC-EXT3-S expansion cards. A total of 30 kinds of function could be selected. | |

Digital output | Standard configuration 2 channel including SP1, SP2 electrode output; 1 channel relay output T1; Expanding 4 channel relay output T2~T5 through SC-EXT2-R expansion cards. | |

High-speed pulse input | HDI: 0~50.0Khz, support by expansion cards SC-EXT1-IO | |

High-speed pulse output | HDO: 0~50.0Khz, support by expansion cards SC-EXT1-IO | |

Communication Port | Communication protocol | Based on RS485 hardware, support standard MODBUS protocol, should match expansion cards SC-EXT1-IO |

Expansion Cards | 3 type expansion cards | Standard expansion cards SC-EXT1-IO, Relay expansion cards SC-EXT2-R (can realize one drives 2 function), Multifunctional input expansion card SC-EXT3-S, refer to the explanation in Appendix. |

Display Functions | Five digital tube display | Can monitor the operation state of frequency inverter flexibly and conveniently; can set normal monitoring parameters separately when operation and stop. |

Protection Function | 25 kinds of protection functions | Including over-voltage, over-current, overheat, overload, under-voltage, short circuit, ground fault, input and output default phase, protect the frequency inverter running reliably all-round. |

Installation Environment Requirement | Ambient temperature | -10degree~+40degree(ambient temperature is within 40degree~50degree, derating use is required), not allow to contact direct sunlight. |

Humidity | Less than 90%RH, without condensation | |

Application environment | Non-corrosive, flammable, explosive, dust absorbent material, all kinds of lint does not accumulate. | |

Vibration | Less than0.6G | |

Elevation | 0~1000m, reduce the rated specification 10% when lift 1000m for each. | |

Storage temperature | -20~60degree | |

Factory Overview

Application

Textiles, Plastics, Ceramics, Electronics, Numerical Controls, Foods Processing, Light Industry, And Pharmaceuticals. Oil, mining and other fields.

Certification

Welcome your inquiry!

Looking forward to cooperating with you!

- Q: Can the laptop power adapter be generic?

- Not necessarily, the laptop power adapter has two interfaces for input and output. 1. Input interface is connected to the power outlet, generally divided into two holes and three holes, as well as round mouth and flat mouth of the points; 2. Output interface is connected to the computer side, size, length, diameter, diameter, the pin may have differences, common are: diameter 2.5MM, ordinary mouth, mainstream interface; OD 1.7MM, small mouth; MM, big mouth with a needle, round mouth with a needle and so on. 3. Different voltage, different brands of laptop power adapter voltage is not the same 4. Current is different, different brands of notebook computer power adapter current is not the same In summary, the laptop power adapter between the different types, basically not common

- Q: Does the teacher know the working principle of the inverter?

- The frequency converter is an AC-DC-AC power electronic device that converts 50 Hz AC sine wave into straight high voltage direct current and then converts it into an AC power that can control the voltage and frequency, driving the three-phase AC motor.

- Q: Is the inverter output current proportional to the output torque?

- When 50HZ or more, the voltage is not increased, the magnetic flux decreases. P = T * n / 9550, if the motor output torque does not change, the current will increase, the motor heat overload

- Q: My inverter is the era TVF8000 series, the motor is 15KW6 pole motor, has been used for 3 years.

- Motor current when the current 10A this has no effect on you, the rated current is 31.4A, your inverter is selected how many W, is the fan pump type or universal? Now the motor operating current reached 34-35A, more than the rated current, then the motor may have two problems, one is the motor leakage powerful, and in a motor is overload, resulting in increased current

- Q: Delta VFD-F frequency converter how to adjust the number of poles

- P148 look, this is to correspond to the number of poles of the motor, not to adjust the number of poles of the motor

- Q: How to choose the inverter

- I was doing the inverter, you choose the words, as long as 75KW can be selected, huh, huh, because the 1440 speed is fixed, the connection can be set in the inverter itself,

- Q: Do you need to rectify before switching?

- I used to do the frequency of the words to be rectified

- Q: Which machines are used for the frequency converter

- Used on a motor that needs to change the speed to change the power.

- Q: How many types of CVT are classified?

- CVT (Continuously Variable Transmission) technology that is continuously variable technology, which uses the belt and the working diameter of the main and driven wheel to match the power to transfer, you can achieve a continuous change in transmission ratio, resulting in transmission and engine conditions of the most Good match

- Q: What is the difference between the collector and the emitter mode?

- This physical structure is intended to facilitate the need for positive enlargement.

Send your message to us

7.5kw 380v 3 phase variable frequency drive ac motor controller

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches