Gold Aluminum Foil Sheets - 5083 Aluminium Alloy Plate for Marine/Aluminium Cast Plates 5083 5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

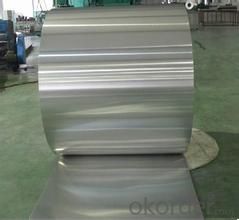

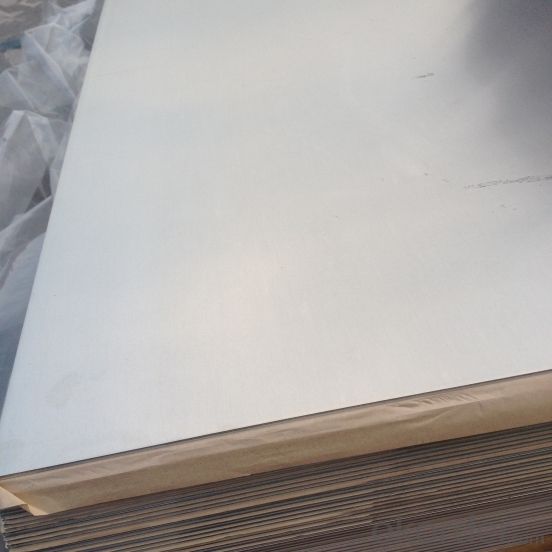

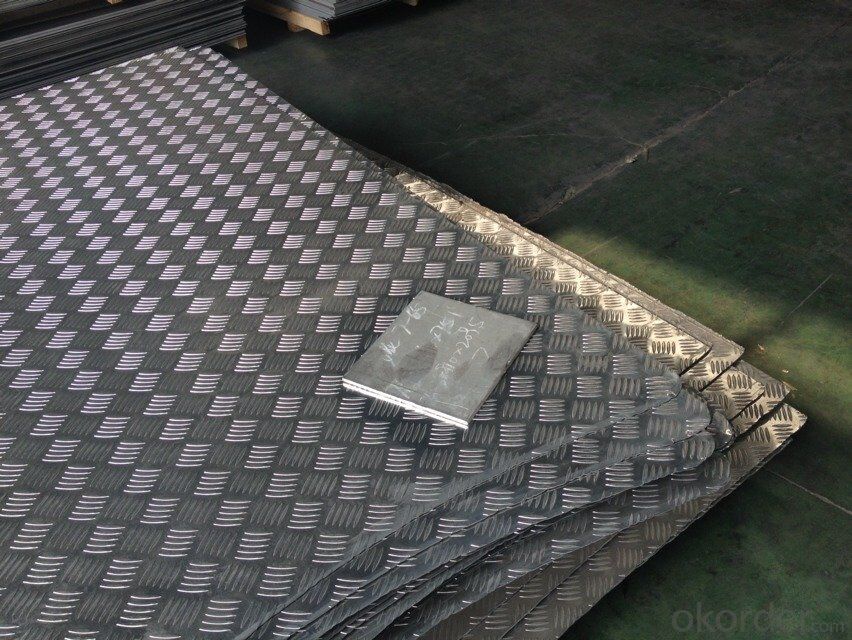

Aluminum Sheet for Making Aluminum Composite Panel

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Discription:

Width: 50-800mm

Thickness: 8-25mic

Length: 3-300m

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: write a balanced equation for the reaction between aluminium metal and potassium hydroxide in water

- Hi there! So you're given Aluminum metal, which has the oxidation state (almost always) of 3+. In play are: Al 3+ K+ OH- You have KOH(aq) + Al 3+ and they react to form a precipitate, creating Al(OH)3 and the potassium cation disperses into solution. In traditional symbols: 3 KOH (aq) + Al 3+(s) ----- Al(OH)3(s) + 3K+ (aq) That's 3 K+, 3 OH-, and 1 Al 3+. That carries for both sides! NIE would look like: 3 OH- + Al 3+ ----- Al(OH)3 (s) Most instructors don't mind if you leave off (aq) but pretty much all of them care about (s), so make sure you add those phase states! I hope I helped :)

- Q: Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Indeed, aluminum sheets are well-suited for the production of electronic enclosures. The reason for aluminum's popularity in this regard lies in its remarkable combination of strength, durability, and lightness. Moreover, its capacity for conducting electricity effectively qualifies it for dissipating the heat generated by electronic components. Furthermore, aluminum sheets can be effortlessly molded, shaped, and machined to meet the precise specifications of electronic enclosures, thereby allowing for personalized and adaptable designs. Additionally, its ability to resist corrosion renders it suitable for safeguarding electronic devices against environmental elements. In summary, aluminum sheets offer the perfect material solution for the manufacturing of electronic enclosures.

- Q: Can aluminum sheets be used in the aerospace industry?

- Indeed, the aerospace industry does employ aluminum sheets. Aluminum, being a lightweight material with a remarkable strength-to-weight ratio, is highly favored for numerous aerospace purposes. Its usage is prevalent in the manufacturing of aircraft structures, including fuselages, wings, and panels. The adoption of aluminum sheets in the aerospace sector offers several advantages, encompassing diminished fuel consumption due to weight reduction, enhanced maneuverability, and heightened payload capacity. Furthermore, aluminum showcases excellent resistance to corrosion, a vital trait for aircraft operating in harsh environmental conditions. All in all, the aerospace industry extensively relies on aluminum sheets, owing to their advantageous properties and exceptional performance.

- Q: Also what are some intersting facts about Aluminum? (the element) thanks 2 any 1 who answers =)

- Aluminum is a versatile material with vast applications in engineering, aerospace and automotive industries. Some of its desirable properties include lightweight (relative to steel) and high strength. The metal is however rarely used in its pure form, it is often alloyed with other elements such as Mg, Manganese, chromium, Titanium to fine tune its mechanical, chemical and or physical properties and tailor it to specific applications. However, in some applications other materials are preferred, for example, Magnesium, due to its higher strength to weight ratio is increasingly replacing Al in transmission casing of automobiles. Also, Compacted Graphite cast Iron is preferred in engine blocks because of its superior strength at high tempreatures, dimensional stability and wear resistance. Auto engines work at very tempreatures and alloys that are capable of withstanding high pressures while maintaining stability are critical. CGCI performs better than Al in this situation. Al alloys remains an important engineering materials though.

- Q: What safety measures should be considered when handling large quantities of aluminum sheets?

- <p>When working with large amounts of aluminum sheets, it's important to take several precautions. Always wear protective gloves and eyewear to prevent cuts and eye injuries. Ensure good ventilation to avoid inhaling aluminum dust, which can be harmful. Use proper lifting techniques to avoid back injuries, and never exceed the weight limits of any equipment. Store aluminum sheets in a dry, cool place to prevent corrosion. Be cautious of static electricity buildup, which can be a fire hazard, especially in dry conditions. Finally, be aware of the risk of aluminum dust igniting, so avoid open flames and sparks near stored or processed aluminum sheets.</p>

- Q: Can aluminum sheets be used for decorative purposes?

- Yes, aluminum sheets can be used for decorative purposes. They are versatile and lightweight, making them ideal for various applications such as interior design, architectural accents, signage, and decorative panels. Aluminum sheets can be easily shaped, painted, or engraved, allowing for endless possibilities in creating beautiful and eye-catching decorative elements.

- Q: 6061-T6 can aluminum sheets be bent?

- It can be bent, but the hardness of T6 series is higher, and the edges of the sheets are easy to wrinkle or split

- Q: Are aluminum sheets suitable for use in electrical applications?

- Yes, aluminum sheets are suitable for use in electrical applications. Aluminum is an excellent conductor of electricity, and its high conductivity allows for efficient transmission of electrical current. Aluminum sheets are commonly used in electrical applications such as power transmission lines, electrical wiring, and electrical enclosures. Additionally, aluminum is lightweight, which makes it easier to handle and install. It is also resistant to corrosion, which ensures long-term durability and reliability in electrical systems. However, it is important to note that aluminum has a lower conductivity compared to copper, so it may require larger gauge sizes to compensate for this difference. Overall, aluminum sheets are a viable and cost-effective option for various electrical applications.

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed.

- Q: I know 7005 series aluminum is stronger and lighter than 6061series, but how does 7005 compare to 2014 series?

- i okorder

Send your message to us

Gold Aluminum Foil Sheets - 5083 Aluminium Alloy Plate for Marine/Aluminium Cast Plates 5083 5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords