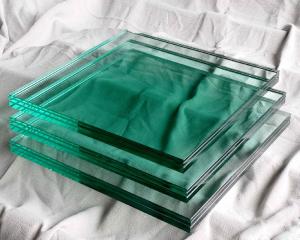

4.0mm AR coated float glass ( for LED light)

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

4.0mm AR coated float glass

Low iron ultra clear float glass mainly used on solar panel because ofits super light transmittance rate. Solar

panel is a thin layer ofoptoelectronic semiconductor which converting solar energy into electricity. By considering

its efficiency, we are using High transmittance and low reflectionglass for its panel. This high strength glass

maintains the best image qualityby elimination unwanted distortions with the advanced optical technology.

Terms | conditions |

Thickness | 3.2mm,4.0mm,5.0mm,6.0mm,8.0mm |

Light transmitance | 94-98% |

function | self cleaning |

applications | solar module,PV module,water heater,led street light,etc. |

payment terms | 40% TT in advance,balanced before shippment . |

delivery | whitin 15 days after receiving the deposit |

packing | pallet ,carton or wood case all available . |

certification | TUV&ISO9001 |

features | smooth ,clear and flat surface |

MOQ | 1000square meters |

Port | Ningbo or shanghai |

1.Reply your inquiry in 24 working hours.

2.Customized design is avaliable ,OEM is welcome .

3.Delivery the goods to our customer all over the world withspeed and precision.

4.Offer customer the products with good quality andcompetitive price .

- Q: What is this wall of glass building material called?

- Architectural glass: Humans learn to use glass has been a thousand years of history, but more than 1,000 years, as the development of architectural glass material is relatively slow. With the development of modern science and technology and glass technology and the improvement of people's living standard, the function of architectural glass is no longer just to meet the lighting requirements, but to have to adjust the light, thermal insulation, security (bulletproof, anti-theft, fire Radiation, anti-electromagnetic interference), art decoration and other characteristics. With the continuous development of demand, glass molding and processing technology has also been a new development. Now, new technologies such as interlayer, tempered, ion exchange, glazed decoration, chemical thermal decomposition and cathodic sputtering have been developed to increase the amount of glass in the building and become the third largest building behind cement and steel material.

- Q: What is the material of the protective film in the middle of the glass

- Tempered glass film with the raw materials are generally Japan's Asahi pin and domestic Los glass, The production process is: 1: open material, the whole glass is cut into larger than the size of 0.6mm small pieces. 2: CNC carved, will open a good piece of gold with steel sand grinding head down, drilling (or slot), CNC carved after the glass was formed 3, flat grinding, mainly dealing with open materials and CNC caused by surface scratches. 4: cleaning, with ultrasonic cleaning machine will be washed, while the glass drying. 5: steel, with potassium acid to strengthen the glass, so that the glass stress, strength, resistance to meet certain requirements. 6: cleaning: the tempered glass into the ultrasonic cleaning. 7: posted AB glue 8: Packaging finished product

- Q: New glass features

- plate glass Flat glass is not processed by other flat glass products, also known as white glass or clean glass. According to the production method is different, can be divided into ordinary flat glass and float glass. Flat glass is the largest in the building glass, the most used one, mainly for doors and windows, from lighting, enclosure, insulation, sound insulation and other effects, but also further processed into other technical glass of the original film. Flat glass according to its use can be divided into window glass and decorative glass. According to the national standard "ordinary flat glass" and "float glass" provisions, the glass according to its thickness can be divided into the following specifications: In accordance with national standards, flat glass according to its appearance quality classification grading, ordinary flat glass is divided into superior products, first-class goods and second-class three grades. Float glass is divided into three grades: superior grade, first grade and qualified product. Flat glass use has two aspects: 3 ~ 5mm flat glass is generally used for doors and windows of the lighting, 8 ~ 12mm flat glass can be used to cut off. Another important use is as the original film of tempered, interlayer, coated, hollow and other glass.

- Q: The state is the number of buildings above the tempered glass

- Tilt the installation window, all kinds of ceiling (including skylights, lighting top), ceiling;

- Q: Is nano-glass insulated paint a lie?

- It was mentioned on behalf of the effect of more understanding of nano-materials nano-glass coating insulation I personally think that may

- Q: What are the shortcomings of the explosion-proof membrane itself? Will there be any adverse consequences?

- Explosion-proof film than ordinary insulation film thickness, so that the glass is not easy to be crushed, if the film is selected when the poor quality of the brand, when the danger occurs when you want to break the glass from the car to escape are not easy, so that the explosion- Hidden film. Another explosion-proof membrane insulation rate is relatively low, generally not as good as the effect of insulation film.

- Q: What is Article 20 of the Regulations on Safety Management of Building Glass?

- Four of the "building safety glass management regulations" (development and operation [2003] 2116) only 14, is not the twelfth ah? Article 12 Penalties ??(1) The safety glass production enterprise shall bear the corresponding legal responsibility for the serious economic loss or personal injury or death caused by the quality of the safety glass itself. The quality supervision department shall supervise and inspect the quality of its products and, if it fails to meet the quality requirements, It shall impose penalties on it, and the compulsory certification body shall revoke its certification certificate in accordance with the relevant provisions. According to the relevant provisions of the punishment, the certification body should bear the relevant legal responsibility. ??(2) The sales unit shall bear the corresponding legal responsibility for the unit that sells the unqualified safety glass in violation of these Provisions and the major economic loss or personal injury or death caused by the products it sells. ??(3) Any trade contract involving the import of unqualified safety glass in violation of these Provisions shall be subject to corresponding legal liability for causing significant losses or personal injury or death caused by the imported products. ??(4) The construction, design, construction and supervision units that violate these Provisions shall be punished by the construction administrative department in accordance with the relevant provisions. The unit that sells the unqualified safety glass in violation of the provisions shall be investigated and dealt with by the administrative department for industry and commerce according to law.

- Q: Standard Specification for Building Timber Glass 3C Marking

- 3C certification mark the glass will be tempered glass, because the glass is the basic requirements of safety glass.

- Q: Information about the new glass Jijiji hurry! Tell me today

- Chemical tempered glass is by changing the chemical composition of the glass surface to improve the strength of the glass, the general application of ion exchange method for steel. The Li + ion exchange layer is formed on the surface by Li + ion exchange layer, and the Li + ion exchange layer is formed on the surface of the Li + ion exchange layer by adding the Na + or K + ions of the glass surface layer to the Li + ions in the lithium (Li +) salt in the molten state, The expansion coefficient is less than Na +, K + ions, which in the cooling process caused by the outer shrinkage of small inner shrinkage larger, when cooled to room temperature, the glass will be in the inner layer of tension, the outer pressure state, its effect Similar to physical tempered glass.

- Q: How to install architectural glass insulation film

- Hello: And paste the car membrane process is basically the same, if it is flat glass do not have a membrane, and first to clean the glass, and then cut the film, the film should be appropriate than the glass area, surrounded by extra, generally 5CM, and then removed Protective layer foil, first with a film spray on the glass film and clean the glass on the glass, and then foil, adjust the position after the hard scraping, soft scraping, tendon scraping.

Send your message to us

4.0mm AR coated float glass ( for LED light)

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches