3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm

1. Structure of 3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of 3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

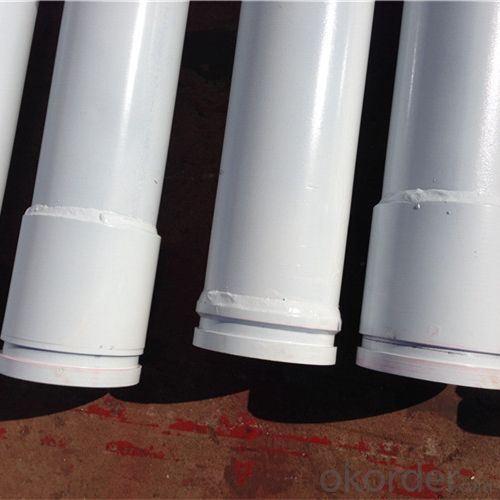

3. 3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm Images

4. 3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm Specification

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

- Q: Are there any specific guidelines for the installation of wear plates or wear rings in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of wear plates or wear rings in concrete pump spare parts. These guidelines typically include ensuring proper alignment and fit, using the correct torque specifications for fasteners, and applying appropriate lubrication. It is important to follow these guidelines to ensure optimal performance and longevity of the wear parts.

- Q: What is the name of the pump for concrete transportation?

- Concrete pump truck is modified on truck chassis. It is equipped with motion and power transmission device, pumping and mixing device, cloth device and other auxiliary devices on the chassis.

- Q: How can you determine when a concrete pump pipe needs to be replaced?

- There are a few signs that indicate when a concrete pump pipe needs to be replaced. First, inspect the pipe for any visible cracks, leaks, or excessive wear and tear. If the pipe shows significant damage or deterioration, it is a clear indication that a replacement is necessary. Additionally, monitor the performance of the pump system. If there is a decrease in efficiency, such as reduced output or increased pressure, it might be due to a faulty pipe. Regular inspection and maintenance will help identify these issues early on and determine when a concrete pump pipe should be replaced.

- Q: How do I properly maintain and replace hydraulic valves in concrete pump spare parts?

- Proper maintenance and replacement of hydraulic valves in concrete pump spare parts involve a few key steps. Firstly, it is crucial to regularly inspect the valves for any signs of wear, damage, or leakage. This can be done by checking the valve body, seals, and connections. Secondly, ensure that the valves are lubricated according to the manufacturer's recommendations to prevent friction and extend their lifespan. Additionally, it is essential to adhere to the specified pressure and temperature limits during operation, as exceeding these limits can lead to valve failure. When it comes to replacement, it is recommended to consult the equipment manual or seek professional assistance to ensure that the correct valves are selected and installed accurately. Regular maintenance and timely replacement of hydraulic valves will ensure the optimal performance and longevity of the concrete pump spare parts.

- Q: How do I properly maintain and replace filters in concrete pump spare parts?

- Proper maintenance and replacement of filters in concrete pump spare parts is crucial for ensuring the smooth and efficient operation of the equipment. Here are a few steps to follow: 1. Regular Inspection: Regularly inspect the filters for any signs of wear, clogs, or damage. Clean or replace them as necessary to maintain optimal performance. 2. Cleaning: If the filters are reusable, clean them according to the manufacturer's instructions. Use compressed air or a mild detergent solution to remove dirt, debris, and clogs. Ensure the filters are completely dry before reinstalling them. 3. Filter Replacement: If the filters are disposable or damaged beyond repair, replace them with suitable replacements recommended by the manufacturer. Ensure that the new filters are of the correct size and specifications. 4. Replacement Schedule: Follow the recommended replacement schedule provided by the manufacturer. Filters may need to be replaced based on usage hours, operating conditions, or as part of routine maintenance. Adhering to this schedule will help prevent premature wear and maintain the efficiency of the concrete pump. 5. Proper Installation: When replacing filters, ensure they are installed correctly, following the manufacturer's instructions. Improper installation can lead to leaks, reduced performance, or damage to the concrete pump. 6. Record Keeping: Maintain a record of filter replacements, cleaning, and maintenance activities. This will help track the lifespan of filters, anticipate replacement needs, and ensure timely maintenance. By following these steps, you can ensure that the filters in your concrete pump spare parts are properly maintained and replaced, promoting the longevity and efficiency of the equipment.

- Q: How often should hopper grate springs be inspected or replaced in a concrete pump?

- Hopper grate springs in a concrete pump should be inspected regularly, ideally on a monthly basis, to ensure their proper functioning. However, the actual replacement of these springs depends on various factors such as the usage intensity, wear and tear, and manufacturer's recommendations. It is essential to monitor their condition closely and replace them promptly if any signs of damage or fatigue are observed.

- Q: How can a faulty accumulator affect the pumping efficiency?

- A faulty accumulator can negatively impact pumping efficiency by causing inconsistent pressure and flow rates in the system. This can lead to excessive energy consumption, reduced overall performance, and potential damage to the pump and other components.

- Q: How often should carbide wear plates be replaced in a concrete pump?

- The frequency of replacing carbide wear plates in a concrete pump depends on various factors such as the quality of the carbide, the amount of usage, and the conditions in which the pump operates. Generally, carbide wear plates may need replacement every 6 to 12 months, but regular inspection and monitoring of their condition is essential to determine the actual replacement interval.

- Q: How often should concrete pump S valves be inspected and replaced?

- Concrete pump S valves should be inspected regularly, ideally every 500 hours of operation or at least once a year. However, the replacement of S valves will depend on various factors such as the quality of the concrete being pumped, the frequency of use, and the overall condition of the valve. It is recommended to consult the manufacturer's guidelines and seek professional advice to determine the specific timing of S valve replacement.

- Q: What are the indications of an inaccurate concrete pump pressure gauge?

- There are multiple signs that may suggest an unreliable concrete pump pressure gauge. Below are a few examples: 1. Inconsistent measurements: If the pressure gauge consistently provides varying readings despite consistent concrete pumping conditions, it could indicate an inaccurate gauge. For instance, if the gauge shows a pressure of 1000 psi one moment and then suddenly jumps to 1500 psi without any significant changes in the pumping operation, it could suggest a problem with the gauge. 2. Abnormal readings: If the pressure gauge consistently displays excessively high or low pressure readings that deviate significantly from the expected values, it may imply an inaccurate gauge. It is crucial to be aware of the usual pressure range for the specific concrete pumping operation to identify abnormal readings. 3. Incompatibility with other gauges: If there are multiple pressure gauges installed in the concrete pumping system and they provide notably different readings, it may indicate that one or more of the gauges are inaccurate. By comparing the readings from various gauges, it is possible to determine if a particular gauge is faulty. 4. Insufficient pump performance: If the concrete pump is not performing as anticipated, such as experiencing reduced output or inconsistent flow rates, it may be a result of inaccurate pressure readings. Inaccurate pressure measurements can disrupt the control of the pump's hydraulic system, leading to inefficiencies in pumping operations. 5. Physical damage or wear: Any visible damage or signs of wear on the pressure gauge, such as cracked glass, bent needles, or loose connections, can compromise its accuracy. Such physical damage can result in inaccurate readings and should be promptly addressed. Regular calibration and maintenance of the pressure gauge are essential to ensure accurate readings. If any indications of an inaccurate gauge are observed, it is advisable to consult a professional technician or engineer to assess the situation and take appropriate actions to rectify the issue.

Send your message to us

3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords