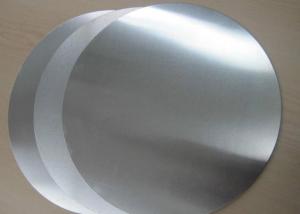

2023 New production High Quality 3003 Alloy Aluminium Circle and Aluminum Disc

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1.Specification & Description

2.Application :

For Aluminium cookware,pot,pan,stock pots,frypan,reflector of the light

3.Packing Pictures

- Q: could aluminum sheet be attracted by magnet?

- no, it couldn't.

- Q: Can aluminum sheets be used in outdoor environments?

- Yes, aluminum sheets can be used in outdoor environments. Aluminum is a highly versatile and durable material that is well-suited for outdoor applications. It has excellent resistance to corrosion, which makes it ideal for withstanding the elements such as rain, snow, and UV radiation. Additionally, aluminum sheets are lightweight yet structurally strong, making them suitable for various outdoor projects such as roofing, siding, and cladding. Furthermore, aluminum is non-combustible, making it a safe choice for outdoor environments. Overall, aluminum sheets provide a reliable and long-lasting solution for outdoor applications.

- Q: Can aluminum sheets be bent?

- Yes, aluminum sheets can be bent as they have malleable properties that allow them to be easily shaped or formed into desired angles or curves.

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Yes, aluminum sheets are suitable for use in cryogenic environments. Aluminum has excellent thermal conductivity and low density, making it an ideal material for cryogenic applications. It can withstand extremely low temperatures without losing its structural integrity or experiencing significant thermal expansion. Additionally, aluminum has good corrosion resistance and can be easily fabricated into various shapes and sizes. These properties make aluminum sheets commonly used in cryogenic systems, such as cryostats, superconducting magnets, and liquid nitrogen storage tanks.

- Q: I need to fix some connections at my dad's house. The original wiring is aluminum, but the newer stuff he did is copper. Simple wire nuts will not suffice. Already had one melted one. I need to fix the connections, but need an economical, safe way of doing it. Suggestions?

- It is safer to replace aluminum with copper. Joints between copper and aluminum tends to oxidize and overheat Electrical fire may happen because of it. In aerial installation, copper is joined to aluminum by means of compression lugs and the lugs screwed together with dow corning compound as anti-oxidant compound

- Q: Can aluminum sheets be easily shaped or bent into desired forms?

- Yes, aluminum sheets can be easily shaped or bent into desired forms due to their malleability and ductility.

- Q: What are the different methods of cutting aluminum sheet?

- Various methods exist for cutting aluminum sheet, each offering unique advantages and applications. 1. Shearing: Employing a sharp blade, shearing provides a quick and efficient process for straightforward cuts. However, it may not be suitable for complex or intricate designs. 2. Laser cutting: By utilizing a high-powered laser beam, laser cutting achieves precise and clean cuts. This method is ideal for intricate designs, allowing for detailed and accurate cuts. Additionally, laser cutting can be automated, making it suitable for large-scale production. 3. Waterjet cutting: With a high-pressure stream of water mixed with abrasive materials, waterjet cutting is versatile and capable of handling various materials and thicknesses. It produces smooth and precise cuts without generating heat, making it suitable for heat-sensitive materials. 4. Plasma cutting: Plasma cutting involves using a plasma torch to heat and melt the aluminum sheet, resulting in a cut. It is a fast and cost-effective method, particularly for thicker sheets. However, the cut may not be as clean as laser or waterjet cutting. 5. CNC milling: By employing a rotating cutting tool, known as Computer Numerical Control (CNC) milling, material is removed from the aluminum sheet to create a cut. This method offers precision and the ability to produce complex shapes and designs. It is commonly used for prototypes or small production runs. When selecting the appropriate method for cutting aluminum sheet, factors to consider include desired cut quality, design complexity, material thickness, and production volume.

- Q: What are the different types of finishes available for painted aluminum sheets?

- Painted aluminum sheets come in various finishes, each with its own distinct features and advantages. 1. For a non-reflective and dull appearance, the matte finish is ideal. This option is commonly utilized in architectural elements and interior design for a low-gloss look. 2. If you prefer a shiny and reflective surface, the gloss finish is the way to go. This finish is often chosen for automotive parts and decorative panels, giving them a sleek and polished appearance. 3. To add texture and patterns to the painted aluminum sheet, opt for a textured finish. This type of finish is commonly used for decorative purposes, enhancing visual appeal and providing a unique tactile experience. 4. Achieve a metallic appearance resembling stainless steel or bronze with a metallic finish. This finish is frequently used in architectural applications to achieve a modern and high-end aesthetic. 5. Powder coating is a popular finishing method where a dry powder is applied to the painted aluminum sheet and cured under heat. This process creates a durable and seamless finish that is resistant to chipping, scratching, and fading. 6. Protect and enhance the durability of a painted aluminum sheet with a clear coat finish. This transparent finish provides an extra layer of protection against UV rays, moisture, and other environmental factors. Consider the intended use and desired aesthetic when selecting a finish for painted aluminum sheets, as each type offers its own unique benefits and characteristics.

- Q: Are aluminum sheets recyclable?

- Yes, aluminum sheets are recyclable.

- Q: Explain how the use of aluminum sheets can impact the visual appeal of a building.

- <p>Aluminum sheets can significantly enhance the aesthetic appearance of a building due to their versatility, durability, and modern look. They offer a sleek and contemporary design, available in various colors, finishes, and textures, allowing architects to create unique and visually striking facades. Their resistance to corrosion and weathering ensures that the building maintains its appearance over time, while their lightweight nature can contribute to innovative architectural designs. Additionally, aluminum sheets can be easily shaped and cut, enabling complex and intricate designs that add to the visual appeal of the structure.</p>

Send your message to us

2023 New production High Quality 3003 Alloy Aluminium Circle and Aluminum Disc

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords