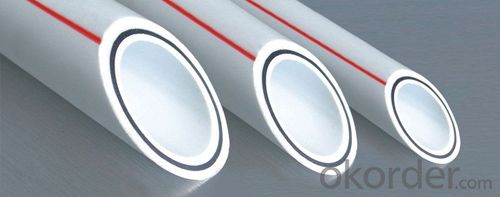

Durable Quality 2024 PP-R Plastic Tubes for Household Pipes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Our Products:

1.It is used in industrial fields, agriculture and garden irrigation

2. Beauty appearance.

3.Thermal insulation and energy saving.

4. Easy installation

5.excellent heat resistance and pressure resistance

6. affordable price

Discription:

1. Country of Origin: | China |

2. Colors: | Green/white/grey |

3. Dimensions: | 20-110mm |

4. Material: | Random Polypropylene , Environmental copper or stainless steel |

5. Pressure Rating: | PN10/PN16/PN20/PN25 |

6. Connection: | Socket fusion joint, electro fusion joint or transition joint |

7. Temperature: | Maximum sustained temperature is up to 70°C, maximum transient temperature is 95°C |

8. Non-toxic: | No heavy metal additives, would not be covered with dirt or contaminated by bacterium |

9. Corrosion Resistant: | Resist chemical matters or electron chemical corrosion |

10. Long life: | More than 50 years under normal conditions |

Specifications:

PPR PIPE

1) Material:HYOSUNG R200P, Basell H5416

2) Size:20-160MM

3) Standard:DIN8077/8078

4) Pressure:PN10

PPR Pipes Advantages:

1. Sanitization & Non-poison: This product is green building material which is able to use for pure clean drinking water pipe system. No heavy metal additives would not be covered with dirt or contaminated by bacterium.

2. High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

3. Corrosion-Proof & Non-Fouling: Resist chemical matters or electron chemical corrosion. Able to avoid the pipe's fouling or blocking as well as the blemish, rust on basin and bath.

4. Heat Preservation & Energy-Saving: Excellent heat insulation features, minimal thermal conductivity which is only 0.5% of the conductivity of metal pipes.

5. Less Weight & High Strength: Its proportion is only 1/8th of metal pipe’s, with pressure-proof strength up to over 5MPa(50kg/sqcm),high tenacity and impact resistance.

6. Beautiful Appearance & Higher Flow Capacity:Smooth inner and outer surfaces, less flowing resistance, soft color and beautiful figure.

7. Easy and Reliable Installation: Using heat melting joint without sleeve wire, and taking few seconds for connecting and adopting good quality copper inserts to connect the metal pipe and basin.

8. Long Using Life: The pipe system can be used for over 50 years under normal condition.

9. PP-R is recyclable and environmental friendly.

- Q: My child left her pierced earrings on way too long. The plastic backs are hardened onto the post. They are not the flat round ones. These are small clear plastic tubes. There must be a softener of some kind, no? Please help.

- Ok after trying all the same things, my husband took a pair of wire cutters and cut the very end of the plastic back off. The left over plastic part slipped right off and the earring is still able to be used.

- Q: Is there an easy way to remember the color tubes (phlebotomy) and what test they are needed for?

- Phlebotomy Color Tubes

- Q: I have a long flexible 1 plastic tube that is attached to itself forming a closed circuit and I'd like to add an electric blower to it to flow air continuously that will make a small ball go around continuously. I'd like to splice the blower into the 1 plastic tube but need to know where or how to exhaust the air to keep the air circuit moving continuously in one direction.

- The problem is not how to connect the blower, the problem is how to get the small ball to go through the blower (which you can't). What you have to do is to deflect part of the air in the tube to the blower input without allowing the ball to go that path. And then the blower pressurizes the air and injects it downstream of the pick off port. A high pressure low volume blower or pump might be best. That means a small pick off port and a small injection port.

- Q: Which companies manufacture GOOD QUALITY plastic and rubber tubing for use in a molecular biology lab, ie. for condensers, circulators, etc

- Look in Cole-Parmer catalog, or in Fisher scientific, or in VWR or....

- Q: What exactly is tubes in ears?

- Tiny tubes are inserted thru the eardrum in order to relieve mucus and/or fluid that has built up behind the membrane; usually as a result of infection. Eventually the eardrum grows back and the tubes fall out on their own.

- Q: The connection between the plastic tube and the metal tube seems not so simple

- The pipe you want to connect can be connected by the corresponding joint. It's simple

- Q: Can plastic tubes be used for industrial labeling?

- Yes, plastic tubes can be used for industrial labeling. They are commonly used in various industries such as manufacturing, warehousing, and logistics to label products, shelves, containers, and equipment. Plastic tubes offer durability, flexibility, and resistance to water, chemicals, and UV rays, making them suitable for industrial environments. They can be easily customized with labels, barcodes, or QR codes to provide clear identification and tracking.

- Q: How is dialysis tubing different from the plasma membrane? Give two reasons.

- dialysis tubing is a thin plastic tube that is compared to the plasma membrane. dialysis tubing is not a part of cells, it is a plastic prop used for experiments such as testing selective permeability. so there alot of differences, the main one being that the plasma membrane is actually in cells, where as dialysis tubing just reinacts what the cell membrane does.

- Q: Can plastic tubes be used for liquid dispensing in beauty products?

- Yes, plastic tubes can be used for liquid dispensing in beauty products.

- Q: Are plastic tubes suitable for packaging household products?

- Yes, plastic tubes are suitable for packaging household products. They offer durability, flexibility, and are lightweight, making them ideal for a wide range of products such as creams, gels, liquids, and even powders. Plastic tubes also provide excellent protection against moisture, air, and contaminants, ensuring the quality and longevity of the packaged products. Additionally, plastic tubes are convenient for consumers, as they are easy to use, dispense the product efficiently, and can be easily recycled.

Send your message to us

Durable Quality 2024 PP-R Plastic Tubes for Household Pipes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords