2024 Newgreen Rigid PVC Foam Board/Sheet - Plastic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

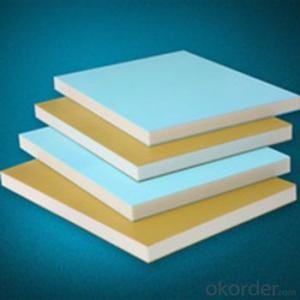

1. Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm or as your request

Thickness:1-33mm

Production Capacity:10000pcs per month

Usage Life: more than 50 years

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

5.FAQ:

(1).How can i get the sample?

If you need samples, we can make as per your request. The samples available for free. And you should pay for the transportation freight.

(2).How long can i expect to get the sample?

The samples available as you ask in 1 days. The samples will be sent via express and arrive in 5~7 days.

(3).Can we have our Logo or company name to be printed on your package?

Sure. Your Logo can be putted on the package by printing or sticker.

(4).Can you cut the PVC foam board and in custom size?

Yes, we have facilities to cut the PVC foam board and mouldings in special sizes. If the size speciation is too complicated or the volume is too many, we will charge processing cost.

6.Product Pictures

- Q: Can plastic sheets be used for stage props?

- Yes, plastic sheets can be used for stage props. They are versatile, lightweight, and can be easily manipulated into various shapes and forms to create the desired effect for a stage production.

- Q: i want to take out my yugioh cards but im afraid i dont want them to lose their color they are all in sheets and im inside my house but the sun is coming from the windows so will they lose color? thanks 5 star automatic

- Don't place them near windows or take them out into direct sunlight. Make sure the sheets you use to cover them are opaque because if light penetrates the sheet they will be discoloured. Put them in a cloth or cardboard cover. That always works. Good luck!

- Q: Company wants me to pay extra for it but why do I need it?

- Probably to keep the moisture in the soil and not make the air under there damp. Wise investment if done properly. I sure hope he intends to put the plastic on the ground, right?

- Q: What are the fire safety ratings of plastic sheets?

- The fire safety ratings of plastic sheets vary depending on the specific type and composition of the plastic. Some plastic sheets may have higher fire safety ratings and be more resistant to ignition and flame spread, while others may have lower ratings and be more combustible. It is crucial to check the fire safety certifications and standards specific to the plastic sheet in question to determine its fire safety rating accurately.

- Q: my car windscreen sticker was full of permanent marker marks done by little kids. i need to lift the marks without spoiling the sticker.

- I am afraid that you may end up to get new sticker. Usually permanent markers can be erased by Acetone, Clorox, or such. However all these chemicals may damage the sticker.

- Q: Can plastic sheets be used for DIY picture frames?

- Yes, plastic sheets can be used for DIY picture frames. They are a cost-effective and lightweight alternative to glass, providing protection for photographs or artwork. Plastic sheets are available in various sizes and can be easily cut and shaped to fit different frame designs.

- Q: Can plastic sheets be used as barriers?

- Yes, plastic sheets can be used as barriers. They can be installed as a protective barrier to prevent the spread of germs or as a physical barrier to separate different areas or objects.

- Q: How do you remove the plastic block from the kitchen?

- The recommended comprehensive quality are white beech, white wood, wood, birch or willow saponin that several material: chopping chopping board board plastic cutting board wooden chopping board bamboo chopping board glass and other materials with the characteristics of the chopping board wooden chopping board is far more safe not add the material recommended priority wooden chopping board

- Q: What are the disadvantages of plastic sheets?

- Some disadvantages of plastic sheets include their non-biodegradable nature, which leads to environmental pollution, difficulty in recycling, potential health hazards due to the release of toxic chemicals, and limited heat resistance and durability compared to other materials. Additionally, plastic sheets may lack the aesthetic appeal and natural feel of alternative materials like wood or glass.

- Q: Are plastic sheets fire-resistant?

- No, plastic sheets are generally not fire-resistant.

Send your message to us

2024 Newgreen Rigid PVC Foam Board/Sheet - Plastic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords