2016 fully automatic electric carton box pp belt bundle strapping machine

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 700 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

2016 fully automatic electric carton box pp belt bundle strapping machine

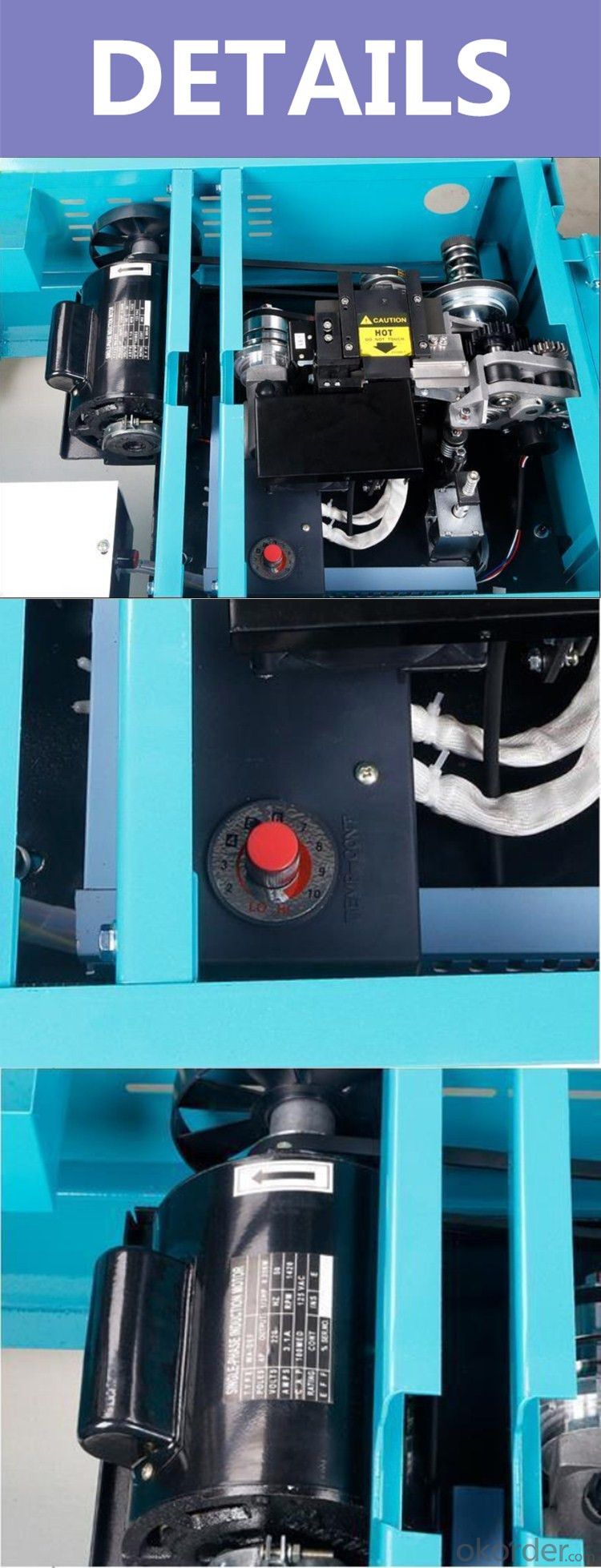

DETAILS

The Specification of Strapping machine LF101A | |

ITEM | LF101A |

Color | Grey |

Machine dimension | L1400*W640*H1475mm |

Strap width | 50mm |

Machine weight | 200kg |

Voltage/power | 380V/50HZ |

Strap width | 50mm |

Shrinking force | 25 - 700 KG |

Automatic Grade | Automatic |

Max Strapping size | 800mm*600mm |

Strapping speed | ≤2.5Second/Strap |

Strap types | PP or PE |

MORE PRODUCT

Our Factory

AFTER SERVICE

we can provied engineers available to service machinery overseas

Free replacement easily damaged parts for 1 year

CONTACT US

JUST CONTACT ME TO GET THE QUOTATION.

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is suggested that displacement or velocity should be detected on the transport path of the membrane. Is a more reliable control signal. Of course, you can also detect the angular speed of the recovery drum, such as a code dial and other simple institutions.

- Q: What is the price of a small jujube packing machine?

- What is the price of a small jujube packing machine?

- Q: What's the best place to use the pillow type packing machine?

- In the early communication can be reflected, and sometimes non-standard customized to see the level of Technology

- Q: What is the name of the paper used in packing machine parts and yellow?

- Rust preventive action, commonly used for steel vapor rust preventive paper, but also for a variety of metals.

- Q: What is the delay time of the packer's cross sealing?

- The sealing time is how long the delay is when the sealing dies are joined together.

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resin is a water-soluble resin, easily cured, the cured resin colorless, non-toxic, good light resistance, long-term use does not change color, heat molding will not change color, can add various colorants to prepare various brightly colored products.Urea formaldehyde resin is hard, scratch resistant, weak acid, weak base and grease. It is cheap and has certain toughness, but it is easy to absorb water, so it has poor water resistance and electrical properties, and its heat resistance is not highThe use of urea formaldehyde resin is widely used in plastic, mold, laminated plastic, foam, also can be used for the production of water-soluble adhesive, the adhesive for wood; fabric shrinkproof and crepe treatment agent; used as a varnish of paper, in order to improve the wet strength of paper. The following is a simple Shaoxing on it the application of the plastic.

- Q: What are the packaging machines that use temperature control watches?

- A lot of heating machines have to use thermostat

- Q: What does the mechanical equipment include?

- Packaging equipment: packaging equipment, packaging testing equipment, packaging container manufacturing equipment, special packaging equipment, filling equipment, mechanical barcode labeling machines, multi-functional packaging machine, wrapping machine, sealing machine, filling machine, strapping machine, dryerPrinting equipment: coding, inkjet printer, offset press, digital printing machine, flexo printing machine, pad printing machine, screen printing machine, complete set of printing equipment, finishing equipment, pre press processing equipment, printing equipment, printing partsSeparation equipment: filter, filter, oil filter, filter press, purification, filtration, screening, filtration, extraction, filtration, distillation, filtration separator / centrifuge, powder separation equipmentWelding and cutting equipment: electric arc welding head electric welding solder wire welding torch torch Taiwan electrode tip plasma welder welder laser welding friction welding machine more chemical equipment heat transfer equipment, chemical equipment transfer pipeline material environmental protection equipment mixing equipment laboratory equipment pressure vessel instrument and electrical equipment reactor piping and fittings of non-metallic equipment

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- For custom vacuum bags, I would recommend a manufacturer who has customized experience in vacuum bags because it reduces your time cost and offers a lot of advice on packaging design and customization.

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

2016 fully automatic electric carton box pp belt bundle strapping machine

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 700 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords