Geosynthetics and Geotextiles - 2024 Best Price HDPE Waterproofing Geomembrane Liner

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

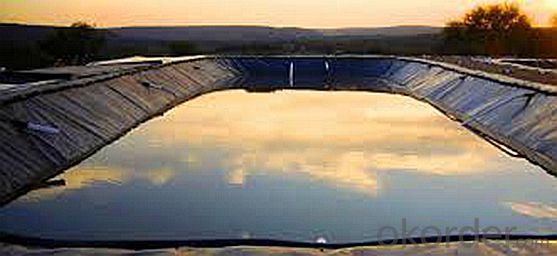

Garden

(artificial lakes, ponds, the lining of tank in golf course, slope protection, ect.)

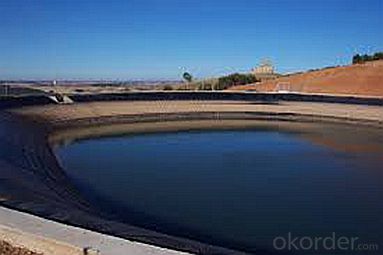

Petrochemical

(chemical plants, oil refineries, oil tank of fill stations , chemical reactions pound, the lining of settling basin, second lining, ect.)

Overall features & benifits

1. Low Permeability - HDPE lining systems are secure because leachate does not

Penetrate them; Methane gas will not escape from the HDPE cover system; And

Rainwater will not infiltrate an HDPE cap.

2. Chemical Resistance - HDPE, resistant to a wide range of chemicals, is not threatened by typical solid or hazardous waste leachates.

It is also suitable for sludge and secondary containment around chemical storage

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the standards and regulations for geotextile products?

- The standards and regulations for geotextile products vary depending on the country and region. However, there are several widely recognized international standards that govern the manufacturing, testing, and performance requirements of geotextiles. These include standards from organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards cover aspects such as strength, durability, permeability, and environmental compatibility. Additionally, various regulatory bodies may have specific requirements for geotextile products, particularly in the construction industry, to ensure their safe and effective use in specific applications.

- Q: What is the separation between the roof waterproof protective layer and the waterproof layer?

- The meaning of the protective layer and the isolation layer is not the same, figured out the role and meaning of nature know how to set up. 1, the protective layer of the waterproof layer contains a two-tier meaning. First, if there are other waterproof layer above the construction layer, due to the construction process may cause damage to damage to water, so need to do protective layer; Second, the roof is the function of the master or planting, the activities of personnel may cause damage to water , Need to do protective layer. 2, the role of the isolation layer is also divided into two kinds. First, to prevent the adverse effects of the two kinds of materials (incompatible), with the isolation layer for the interface, such as PVC coil and polystyrene foam insulation board, because the plasticizer in the membrane will migrate , The direct contact with the benzene plate will produce melt damage; Second, the coil surface of the rigid layer, may be due to thermal expansion and contraction deformation affect the waterproof layer, in the rigid layer of the larger part of the deformation, Too large and damage the waterproof layer, then need to set the isolation layer. There is a geotextile isolation layer between the waterproofing membrane and the pebble press material. 3, not all of the waterproof layer and the protective layer between the need for isolation layer. When the cement mortar is used as the protective layer, the cement mortar may be directly applied to the waterproof surface. When the flexible protective material (heat reflective coating, etc.) or the insulation layer is used, the isolation layer is not required.

- Q: Are geotextiles suitable for use in stormwater management systems?

- Yes, geotextiles are suitable for use in stormwater management systems. They are commonly used in a variety of applications within these systems, such as erosion control, filtration, and drainage. Geotextiles can effectively filter sediment and pollutants, prevent soil erosion, and provide stability to stormwater infrastructure.

- Q: What are the benefits of using geotextiles?

- There are several benefits of using geotextiles in various applications. Firstly, geotextiles provide effective erosion control by stabilizing the soil and preventing it from being washed away by water or wind. Secondly, they enhance the drainage system by allowing water to pass through while retaining the soil particles, thus improving the overall performance of the infrastructure. Thirdly, geotextiles act as a barrier to separate different soil layers or materials, preventing their mixing and maintaining their integrity. Additionally, geotextiles can increase the load-bearing capacity of soils, making them suitable for construction or reinforcement purposes. Lastly, geotextiles are cost-effective and easy to install, reducing both the time and labor required for the project.

- Q: Are geotextiles poisonous?

- Geotextile is not toxic, the production of geotextile raw materials are polyester (PET) or polypropylene (PP). Polyester and polypropylene have become daily necessities. Many of the mineral water bottles are also produced by PET and PP raw materials.

- Q: What are the key factors affecting the filtration performance of geotextiles?

- The key factors affecting the filtration performance of geotextiles include the permeability of the geotextile, the pore size distribution, the thickness and weight of the geotextile, the hydraulic gradient, and the particle size of the soil being filtered.

- Q: What are the advantages of using geotextiles in green building design?

- Geotextiles offer several advantages in green building design. Firstly, they provide effective erosion control by stabilizing soil and preventing sediment runoff. This helps to protect the environment and nearby water bodies. Additionally, geotextiles enhance soil fertility and moisture retention, promoting healthy plant growth and reducing the need for irrigation. They also help in weed suppression, reducing the reliance on herbicides. Moreover, geotextiles can be used to create permeable pavements, allowing rainwater to infiltrate the ground and replenish local groundwater supplies. Overall, the use of geotextiles in green building design improves sustainability, reduces environmental impact, and enhances the overall performance of the project.

- Q: Geotextile standard is broken how low?

- Geotextile of the top of the strong implementation of the national standard GB / T-2008, the standard of the geotextile bursting strength requirements in the international arena is not very low. Geotextile because it is produced by fiber acupuncture, and its breaking strength and elongation at break for the main performance indicators, even in practical applications when we are mainly using these two characteristics of geotextile. Breaking strength is called CBR bursting strength, the main test is the product of anti-puncture, the general waterproof, impermeable material requirements are higher, and geotextile is the filter, the protection of materials, so the standard requirements are lower.

- Q: Can geotextiles be used in groundwater protection systems?

- Yes, geotextiles can be used in groundwater protection systems. Geotextiles are permeable fabrics that can help in filtration and separation of different soil layers. They can be used to prevent the migration of fine particles and contaminants, providing an additional layer of protection for groundwater sources.

Send your message to us

Geosynthetics and Geotextiles - 2024 Best Price HDPE Waterproofing Geomembrane Liner

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords