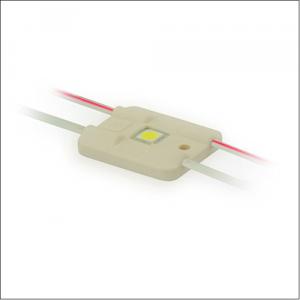

2014 Autonomic Packaging Injection 5050 LED SMD ModuleJg3024Sd1

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 100 Pcs bag

- Supply Capability:

- 100000 Pcs Per Month bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction

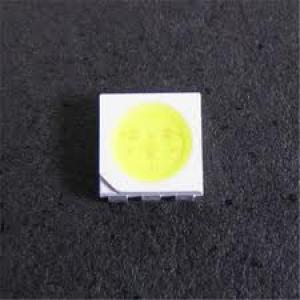

2014 JINGGE Autonomic packaging/ 90lm / 1.08W / DC12V / Injection Molding / Epistar 5050 SMD LED Module

Features

1W high luminous whit light LED.

High quality breakthrough LED product.

Unique design philosophy.

Based on low tension injection-molding technogy.

Jingge autonomic packaging high quality LED high brightness and average lifespan more than 50000 hours.

Specification

Emitting color | white | Wire Type | 20AWG |

Model | JG-3024SD1 | Connected in series max | 20PCS |

Dimension | 30×24×5.4mm | PCB Material | Aluminum Base(JG-2721) |

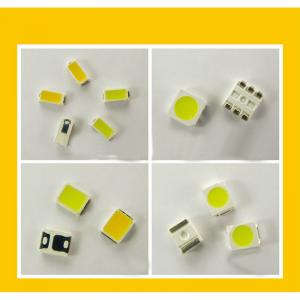

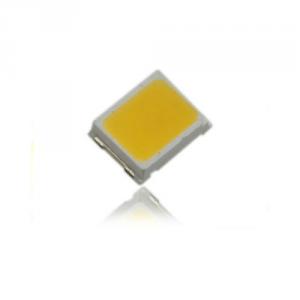

LED Type | 5050SMD | Shell Material | Retardant Flame PVC |

LED Qty | 1PCS | Shell Color | White |

Working Voltage | DC12V | Waterproof Grade | IP66 |

Rated Current | 90mA | Luminous | 90LM |

Rated Power | 1.08W | Average Lifespan | >50000h |

Beam Angle | 120 degree | Working Temperature | -20 to 70 degree |

wire length between modules | 101mm | Storage Temperature | Room Temperature |

Wire Length | 120mm | Certificate | CE Rohs |

Application

1.Widly used in electronic signs,channel letter

2.Backlighting for Advertisement, Signboard and Billbord

3.Backlighting for Lightingbox

4.Signal Lamp for Channel

Our Service

1.We offer high quality LED, inquired will be replied 24 hrs

2.Your special requirement about led light will be acceptable

3.Discount is according to the quantity you ordered

4.Excellent after-sales service

All led module can be done logo according to customer's requirement.

About us

With a professional and creative R&D team,NIT strives to produce high quality LED. From equipments to raw materials (such as chip,lead frame and epoxy), they are all of the first-class in the industry. By studying the essence of the latest manufacturing process,techniques and formula, NIT has developed a series of patent products. In November 2007,NIT broke through the critical defect of white LED by reducing the degradation by 5 times.

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By sea | 30-40 business days |

1. 3-10 business days for Sample Orders; 7-40 business days for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address.

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- When making a batch of LED lights, the brightness values of various lights are in accordance with certain rules. Due to achieve a white balance, three RGB color brightness required by the ratio of 3:6:1, that is to say the blue light required brightness is very low.

- Q: What is the principle used in SMD LED lamp, should pay attention to what the problem?

- LED white is the light emitting diode, a PN junction to the most important use of SMD beads is the heat, according to the different manufacturer beads, glue package is not the same, should pay attention to pre baking time and temperature, the latter should pay attention to the patch temperature, the most important is the price, many manufacturers in order to cost savings, internal chip used is too small does not meet the standards, support steal frugal material, with iron, the failure cycle shortened, LED lamp can not reach the ideal effect. Again, the LED supply current must not exceed the rated value, which is an important factor in damage to lamps and lanterns

- Q: Led lamp and Led patch two what is the difference between ah, the feeling is a patch of long service life, whether or not? 5-10 meters pan area lighting lamp selection Everbright shaped or patch shape?

- First of all, I want to say, in the same light emitting chip case, two is not what were, just a different process is a DIP plugin, a SMD patch process, the 3 floor of the right, just some high grade patch.

- Q: How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

- You can also use the ohmmeter's ohmmeter. To dial multimeter, to "ohm X1" file, the light emitting diode when the red pen is connected to the positive terminal of SMD LED, the black probe is connected to the negative terminal of SMD LED.

- Q: What is patch SMD-LED?

- Semiconductor wafers consist of two parts, one is P type semiconductor, in which the hole dominates, and the other end is N type semiconductor, which is mainly electronic here. But when the two semiconductors are connected, they form a P-N junction between them. When the current passes through the wire acting on the chip, the electrons are pushed into the P region. In the P region, electrons combine with the hole and then emit energy in the form of photons, which is the principle of LED luminescence. The wavelength of light, that is, the color of light, is determined by the material that forms the P-N junction.

- Q: Which is good for LED patch and LED bulb?

- Chip LEDLED patch lamp (SMD) is made of FPC circuit board, LED lamp and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.LED bulbThe light emitting diode, is capable of converting electrical energy into visible solid semiconductor devices, which can be directly converted into electricity to light; LED Large Electronic = Display, LED = large electronic display; Lupus erythematosus disseminatus, systemic lupus erythematosus, a chronic idiopathic autoimmune disease; LED lead the past and past participle, meaning "leadership, led the Russian Pulkovo Airport IATA code.

- Q: Notes on patch LED

- Clean, do not use an unknown chemical liquid to clean the patch LED: an unknown chemical liquid may damage the patch LED. When necessary, immerse the patch LED in alcohol, less than 1 minutes at normal room temperature, and dry naturally for 15 minutes before starting to use

- Q: The ten patch LED lights are connected in parallel. The rated power is 5 watts. How much voltage do you need?

- The voltage needs to be determined according to the product specification, usually 3.1 - 3.5V

- Q: How do led patches measure good or bad?

- Use the two stage tube test of the multimeter, the red pen is connected, and the black pen is negative. If there is a bee, the sound is bad, and if the light is bright, it is good

- Q: SMD LED lamp working voltage?

- Single chip of 1 watts, more than a lot, different colors, the voltage will be different. White is usually 3.0-3.6V.* in addition to their working voltage, working current is more important parameters, once the flow, it will burn out.The LED lamp. With chips is variety, many tricks, they can be connected in series and parallel. The voltage is divided into high voltage, low voltage and medium voltage

Send your message to us

2014 Autonomic Packaging Injection 5050 LED SMD ModuleJg3024Sd1

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 100 Pcs bag

- Supply Capability:

- 100000 Pcs Per Month bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords