18mm OSB Board/MDF Versus Particle Board Film Plywood Factory from AAA Enterprise

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

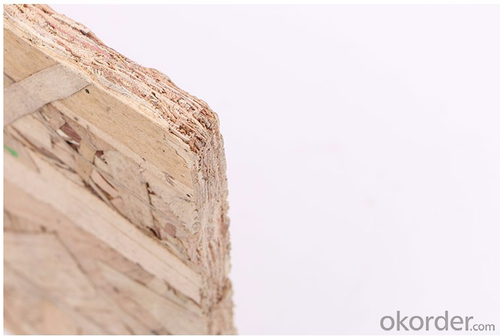

cheap osb board

Product intoduction

Size | 1220*2440*9-25mm, size according to customer requirements for sawing and cutting, ensure the utilization rate of 100%. |

Core | poplar,pine,birch |

Glue | E0/E1/E2 |

Features | light color beautiful, with good strength, for all the raw material, no deformation, good flatness, large bearing capacity, good nail holding power, low price, low price, environmental protection, fumigation-free products. |

Usage | 1.wood structure: exterior wall coating, roof covering, the bottom floor, structural insulated panels, I-beam, single floor. 2. box, boxes, shelves, wooden tray pad ( heavy machinery ). 3. truck body, loading and unloading chassis. 4. display board, liner board / storage box and the storage cabinet / decoration material / fashion furniture, kitchen furniture / concrete building template. |

Capacity | 5000m³/ per month. |

Delivery | 15 days |

Payment | T/T ( 30% advance payment, the remaining payment delivery ) |

- Q: According to the surface conditions:

- decorative particleboard: impregnated paper finishes particleboard; decorative laminate veneer particle board; veneer veneer particleboard; surface coated particleboard; PVC veneer board and so on.

- Q: The Particleboard quality identification editor

- including North China, northwest, northeast plate moisture content is generally controlled at 6-8% is appropriate; the southern region,

- Q: Particleboard in the production process of environmental performance

- to be stored for some time after the observation room. If no spiky smell that particleboard release of formaldehyde less, the use will not affect human health

- Q: What is the production process of particleboard

- the plate thickness deviation and the degree of material transfer between the shavings

- Q: Raw materials for the production of particleboard include

- Preparation of wood shavings processing equipment are chipper, re-crusher, grinding machine and fiber separator, cutting methods are cutting, cutting and broken.

- Q: Particleboard of the unfavorable factors

- ut also the main application of innovative results. From a national perspective, the number of patented wood-based panel enterprises, the number of patent applications and patent applications rarely,

- Q: According to the use of points: Class A particleboard; Class B particleboard

- gradient structure particleboard; oriented particle board; waffle particle board; molded particleboard.

- Q: How to improve the particleboard market space

- In order to improve the quality of the particleboard and reduce the cost and improve the research and development capabilities

- Q: What are the disadvantages of particleboard?

- but with the country's attention to environmental protection, high-quality particleboard environmental protection has been protected.

- Q: The product structure of the wood-based panel industry

- In addition, the orientation of particleboard, wood-plastic composite panels, waffles and crop straw board and other products of immature technology,

Send your message to us

18mm OSB Board/MDF Versus Particle Board Film Plywood Factory from AAA Enterprise

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords