18in Mill Finish Aluminum Sheets for Metal Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum Sheet for Metal Roofing

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finish Aluminum Sheet for Metal Roofing

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Sheet for Metal Roofing

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

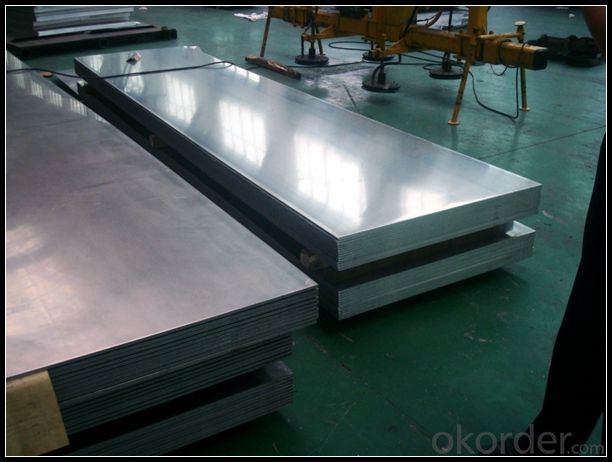

5. Image of Mill Finish Aluminum Sheet for Metal Roofing

6. Package and shipping of Mill Finish Aluminum Sheet for Metal Roofing

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different methods of bending aluminum sheets?

- There are several methods of bending aluminum sheets, including air bending, press brake bending, roll bending, and stretch forming.

- Q: When zinc dust and sulfur dust are combined in certain proportional ratios and ignited, a violent exothermic reaction occurs. Because the reaction only depends on two components; zinc and sulfur, but not oxygen, the reaction has all of the components that it needs within the mixture. The same is also true for a mixture of magnesium and sulfur.However, the same reaction does not occur with iron and sulfur. Instead, the mixture reacts slowly over a period of a few minutes rather than flashing to smoke in less than a second. Now for my questions:1: If aluminum and sulfur were combined in the same proportional ratios as the zinc and the magnesium mixtures were, would the reaction be as fast as the zinc and the magnesium mixtures? Why or why not?2: What properties of the different metals used in these mixtures makes them behave so differently?

- the forged iron crucible will honestly be dragging the warmth away,so attempt to discover a ceramic crucible---you will possibly have the potential to discover them at any rings furnish domicile.you will additionally so discover commercially arranged fluxes for melting,if no longer Borax powder is a fluxing agent I generally use.With the small quantity of meral you're wishing to soften,i think of your MAPP torch ought to artwork,be confident to change the flame to a lowering flame to steer clear of gassing the metallic.the availability domicile RIOGRANDE has an entire inventory of something you are able to require besides as some preprepared alloys which you will choose to objective.

- Q: What does everyone think about replacing aluminum bats with wooded ones in high school. More and more cities are going back to wood.........why

- Simply put, the risk of somebody incurring a serious injury or even death is starting to outweigh the financial benefits of using aluminum over wood. The increase of velocity of a pitched ball coming off a wooden bat compared to one coming off aluminum is tremendous. Specifically pitchers and corner infielders are put at major risk each and every time they play games against hitters using aluminum bats. Places that once thought of saving money by not having to replace broken bats are wisely chosing to put a higher price tag on a players health. It should be a universal thought, but sadly there are some who still endanger players everyday by allowing aluminum bats...they are the ones who should consider the cost of a wooden bat vs. the cost of an athletes health.

- Q: Are aluminum sheets suitable for roofing systems?

- Indeed, aluminum sheets prove to be an appropriate option for roofing systems. The durability, lightweight composition, and corrosion resistance of aluminum render it a favored choice for rooftops. Moreover, aluminum possesses fire-resistant properties and can endure harsh weather conditions, including strong gusts and heavy precipitation. With their long lifespan and minimal upkeep requirements, aluminum roofing sheets present a financially sound choice over time. Furthermore, the highly reflective nature of aluminum aids in reducing energy expenses by maintaining cooler indoor temperatures in hot climates. In summary, aluminum sheets emerge as a dependable and effective preference for roofing systems.

- Q: As for cast aluminum sheet or wrought one, which one has faster heat conduction?

- 1,duralumin: it's the alloy of aluminum, copper, magnesium, manganese and other metals. it's suitable for compacting by rolling, and it has a higher strength and hardness than common aluminum products. 2, aluminum: it contains many inpurities, is crisp and easy to be smashed.cast aluminum usually is secondary aluminum, and it is produced by remelting the collected old aluminum pots and spoons.3, wrought aluminum: it contains 98% aluminum and 2% or more inpurities, and is comparatively pure aluminum. its soft priority makes it suitable for being pressed into various shapes, aluminum pots,aluminum lunch box,aluminum sheets,aluminum wires,aluminum pipes are all made by wrought aluminum.you will know their defferences from their definition.

- Q: So I got this stainless steel ring but I took it to this place and apparently its not stainless it's aliminum bc of how light it is but it's really hard so how could it be aluminum?

- Aluminum is a quite soft metal, but so is gold. It is true that aluminum is light in weight but magnesium is even lighter and is common enough that a ring could be made of it. Metals can be made harder by adding small amounts of other metals or even by the way it is heat treated. .

- Q: Is it possible to use aluminum sheets for exterior siding purposes?

- <p>Yes, aluminum sheets can be used for siding applications. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum siding is lightweight, easy to install, and can be painted to match various architectural styles. It's also resistant to rot, termites, and fire, making it a popular choice for many homeowners and builders. However, it's important to ensure that the aluminum is of high quality and installed correctly to maximize its benefits.</p>

- Q: This question asks whether it is possible to utilize stamped or embossed aluminum sheets for a specific project.

- <p>Yes, you can use stamped or embossed aluminum sheets in your project. These sheets are known for their strength, durability, and lightweight properties, making them ideal for various applications such as construction, automotive, and aerospace. Stamped aluminum sheets are formed by pressing the material into a specific shape, while embossed sheets have a raised pattern. Both types offer design flexibility and can be customized to meet specific project requirements. Ensure that the aluminum sheets you select meet the necessary specifications for your project, such as thickness, strength, and finish.</p>

- Q: What is the typical wear resistance of aluminum sheets?

- The wear resistance of aluminum sheets can vary depending on the specific alloy and temper. Typically, aluminum sheets exhibit a moderate level of wear resistance compared to other metals. However, they do not possess the same level of wear resistance as materials like steel or titanium. Aluminum sheets can endure light to moderate wear and abrasion, making them suitable for applications that do not involve excessive friction or impact. To improve the wear resistance of aluminum sheets, various treatments such as anodizing or painting can be applied to their surface. Furthermore, the wear resistance of aluminum sheets can also be influenced by their thickness and hardness. In general, thicker and harder sheets tend to offer better resistance against wear.

- Q: Are aluminum sheets suitable for structural applications?

- Yes, aluminum sheets are suitable for structural applications. They are lightweight, yet strong and durable, making them ideal for various structural uses such as building facades, roofs, and transportation vehicles. Additionally, aluminum sheets have excellent corrosion resistance, which further enhances their suitability for structural applications.

Send your message to us

18in Mill Finish Aluminum Sheets for Metal Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords