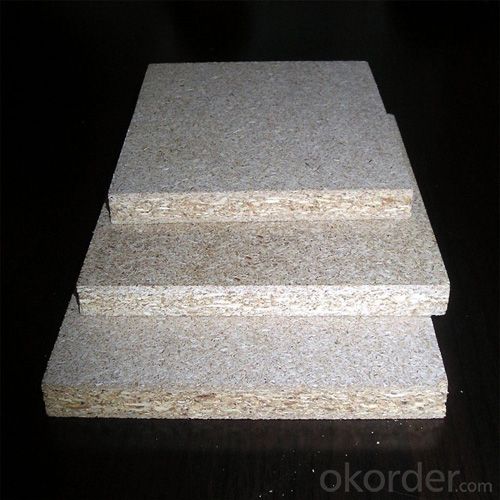

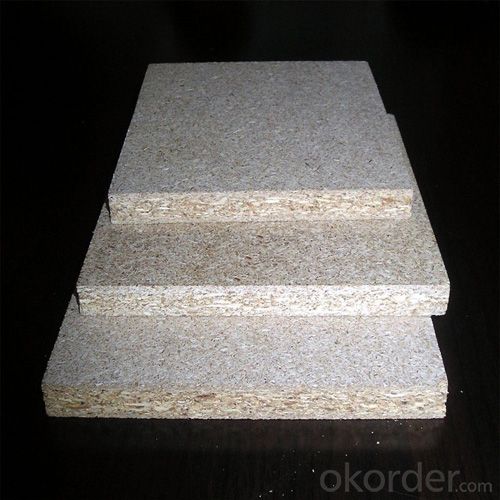

15 mm Thickness Chipboard with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Fibreboards

· Place of Origin: Shandong, China (Mainland)

· Material: Wood Fiber

· Usage: Indoor

· Grade: First-Class, First-Class

· Fibreboard Type: Low Density Fibreboards / Softboards

· Formaldehyde Emission Standards: E2

· Density: 600kgs/m3

· Veneer: raw or melamine paper

· Thickness tolerance: ±0.2mm

· Core: poplar

Packaging & Delivery:

Packaging Details: | Standard export packing. Each bundle will be protected with plastic membrane to seal well, using protect-board for the top and the bottom, the thickness should not less than 4mm for top, and not less than 10mm for bottom |

Delivery Detail: | 15 days after getting your 30% deposit |

Specifications:

Best price chipboard 15mm :

1.Size: 1220X2440mm

2.Thickness: 12/15/16/18/22/25/27mm

3.Glue: E2

4.Certificate:CARB ISO9001 IS

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: What is the current project wall, which kind of roof? There are commonly used models

- General factory roof do mineral wool, sandwich tile seems to be through the fire, the wall is generally used a single layer of tile

- Q: Is not allowed to use foam sandwich color plate

- Hello! Now the state banned the use of foam sandwich color steel plate, also known as foam sandwich panels, because the foam sandwich board fire rating is poor, the state is prohibited. Now the market generally use rock wool color plate, which is used instead of rock wool composite board, fire rating up to A level. There are also some high-end customers with polyurethane color plates instead of using them, so the cost may be higher. Choose a most suitable for their own sandwich color plate can be used. After all, who is not the wind to the wind, the ability to do so

- Q: Color plate and color steel sandwich panel difference

- Color steel plate galvanized coated iron plate, the use of color steel plate is not insulated. Color steel sandwich panels are double-sided steel plate with the center of the core material through the machine continuous pressure from the type. The core material has foam, rock wool, polyurethane and extruded. The main feature is the insulation of insulation. hope this helps

- Q: What is the polyurethane fireproof grade?

- Polyurethane sandwich panels are generally fire-resistant B2, can also reach the B1 level, belonging to the B-level self-extinguishing

- Q: Color steel sandwich panel prices

- Foam board 10 kg 0.4 iron 60 yuan up and down. Polyurethane 160 to 220 yuan

- Q: anxious! Will the polyurethane sandwich panels of various parameters, plant design!

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

- Q: Pressure plate composite insulation board and the difference between the sandwich panels, the price difference is large? What kind of geng good for steel structure plant design?

- The top of the plant with sandwich panels

- Q: What are the black glue used in industrial production of sandwich panels? Chemical properties What chemicals are soluble in chemical reagents?

- Two-component polyurethane black and white plastic A component: B part of the white part of white polyester, black special polyester. Specific components are unknown, there are differences between manufacturers. Soluble in ethyl acetate.

- Q: Color steel tile foam sandwich board model is how the classification

- Common sandwich panels: foam sandwich panels, rock wool sandwich panels, polyurethane sandwich panels. Common specifications: roof board 980, wall board 950. Common thickness: 50mm, 75mm, 100m.

- Q: Is the interior material of the rock wool sandwich panel fluffy or compact?

- This is related to bulk density. Big enough to be dense, you can knock to listen to its voice.

Send your message to us

15 mm Thickness Chipboard with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords